Method for mounting ultra-wide ultra-high reinforced concrete beam large-diameter steel bar

A reinforced concrete and installation method technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of narrow working space, difficult tying, and high construction requirements, so as to solve the problem of operating space, shorten the installation period, The effect of reducing the loss rate of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

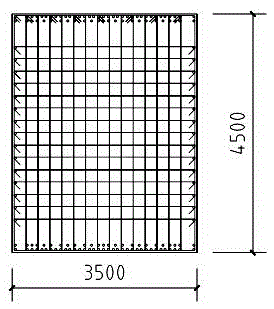

[0028] Embodiment 1: as figure 1 , figure 2 For the reinforced concrete beam with a cross-section of 3500×4500 shown, its reinforcement is as follows: the upper longitudinal stress reinforcement 60 4035 / 25, the lower longitudinal reinforcement 60 4025 / 35, stirrup 16100 (16), Waist N30 40.

Embodiment 2

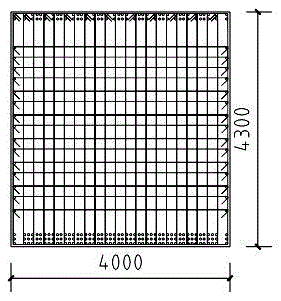

[0029] Embodiment 2: as image 3 , Figure 4 For the reinforced concrete beam with a section of 4000×4300 shown, the reinforcement is: the upper longitudinal stress reinforcement 80 4040 / 40, the lower longitudinal stress reinforcement 150 4050 / 50 / 50, stirrups 16100 (22), loin N30 40.

[0030] (1) The beam reinforcement installation method of Embodiment 1 and Embodiment 2 includes the following steps:

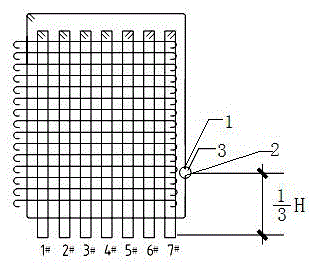

[0031] Step 1: The beam reinforcement project is divided into sections by 1 / 3 of the beam height H in the height direction and installed in sequence, and the length direction is divided by the length of the longitudinally stressed reinforcement supply. Install the internal composite stirrups and the lower longitudinal stress reinforcement within the connection range sequentially from one side;

[0032] Step 2: One side of the closed stirrup on the periphery of the beam is divided into upper and lower L-shaped stirrups 1 and 2 at the position of 1 / 3 of the beam height H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com