Self-locking reverse-spitting-prevention bridge-type concentric adjustable water regulator for separate-layer injection well

A layered water injection, self-locking technology, applied in wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve the problems of single function, increased labor intensity, increased cost, etc. Flexible and accurate water volume, strong self-locking, and anti-vomiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

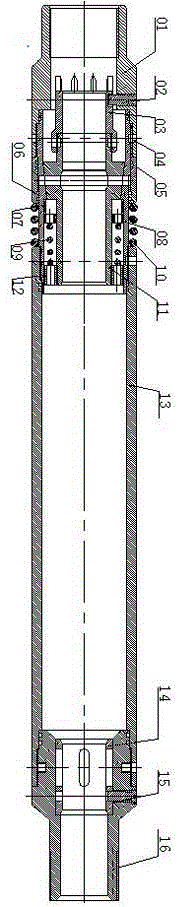

[0018] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0019] The present invention includes an upper joint 1, a positioning screw plug 2, a positioning sleeve 3, a screw 4, a fixed valve 5, a sliding valve 6, a stop sleeve 7, a main body 8, a small pressure spring 9, a large pressure spring 10, and a conversion core 11. Fixed screw sleeve 12, large connecting sleeve 13, anti-rotation sleeve 14, anti-rotation screw plug 15 and lower joint 16, characterized in that: the inner circumference of the upper joint 1 passes through the upper part of the fixed valve 5 and the upper part of the main body 8 through the screw 4 Connection, the lower part of the fixed valve is dynamically sealed with the upper part of the sliding valve sleeve 6, a large pressure spring is provided between the lower part of the sliding valve sleeve and the large connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com