Flexible curtain sealing device for non-pillar roof-cut entry

A sealing device and no coal pillar technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems affecting the normal replacement procedure of the working face, the sealing device cannot be recycled, waste of manpower and financial resources, etc., and achieve the production cost Low cost, good sealing effect, and the effect of saving sealing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

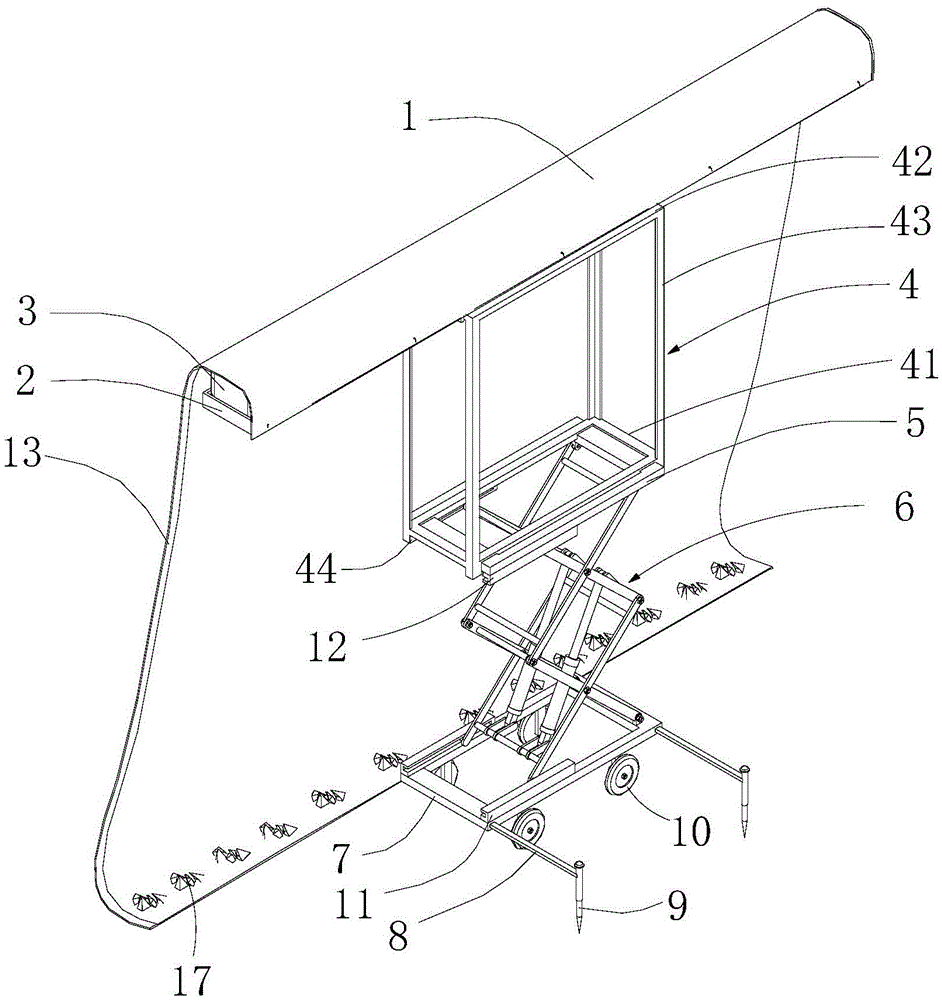

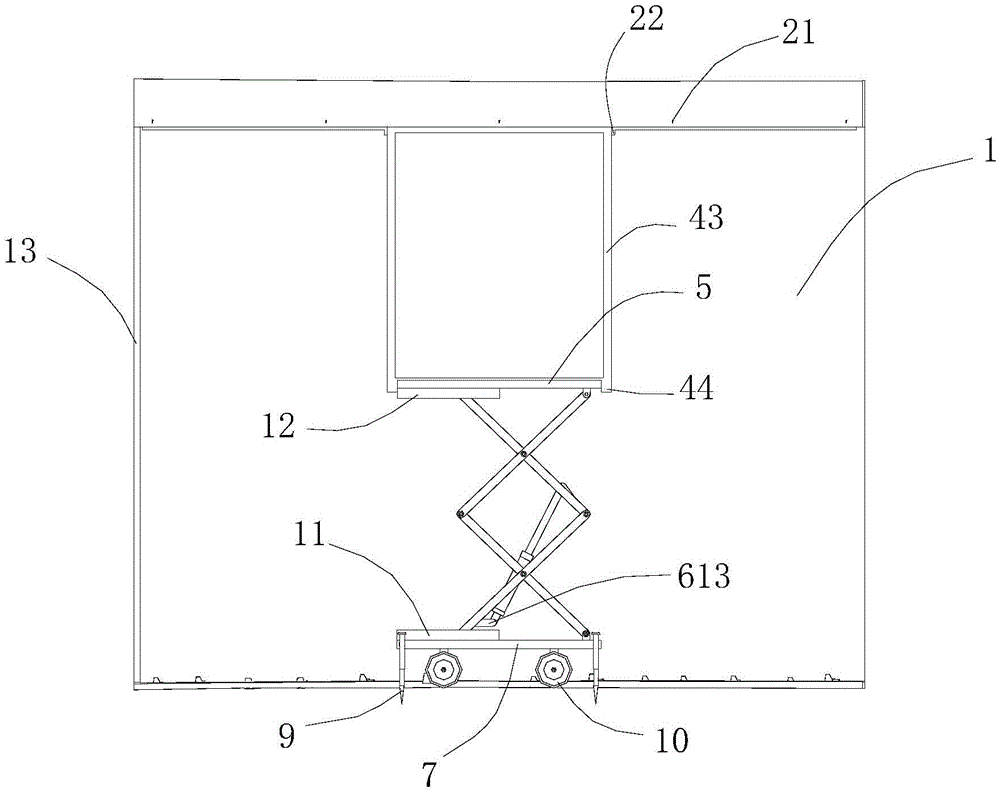

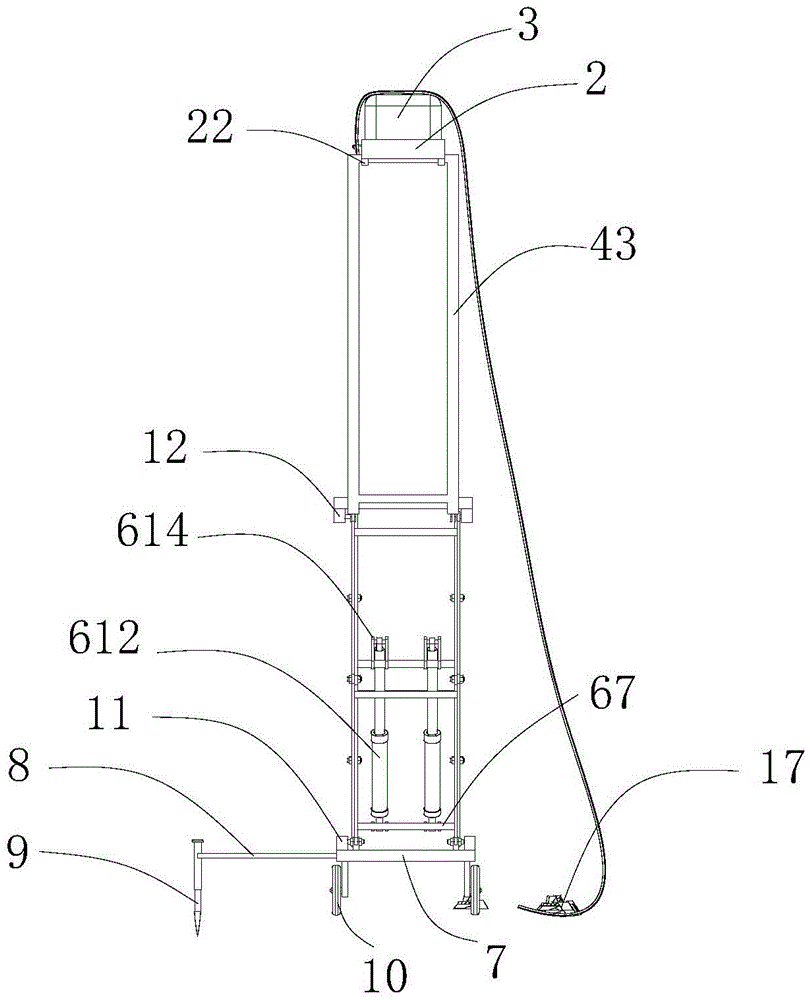

[0031] Such as figure 1 and Figure 6 As shown, a flexible curtain sealing device for roadway cutting without coal pillars, including a sealing mechanism for sealing the roadway when the roadway is retained along the gob, a supporting mechanism for providing support for the sealing mechanism, and driving the sealing mechanism, supporting The mechanism is a lifting mechanism that moves up and down along the height direction of the roadway. The sealing mechanism includes a flexible cord 1. The flexible cord 1 is made of flame-retardant and antistatic soft PVC material. Specifically, it uses high-strength polyester lattice cloth as the skeleton, PVC It is made of plastic filling; the support mechanism includes a support frame 4 and a support block 3 arranged above the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com