A spring buckle for installing an oven sealing strip and its positioning and installation method

A technology of positioning installation and sealing strip, applied in applications, home appliances, kitchen utensils, etc., can solve the problems of reducing the sealing effect, damaging the sealing strip, complicated operation, etc., and achieving the effect of eliminating damage, high work efficiency, and convenient and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

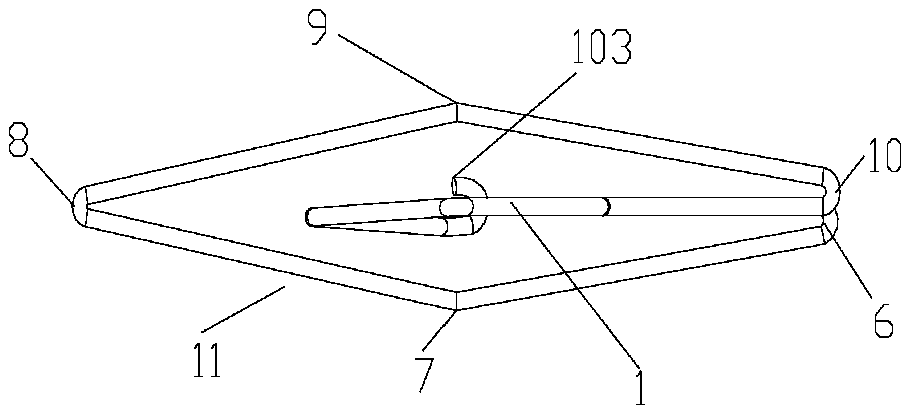

[0041] like figure 1 and figure 2 As shown, the spring buckle for the installation of the oven sealing strip provided by the present invention includes an installation head 1 for inserting into the oven slot and a base 11 connected with the installation head 1, and the base 11 is connected by a plurality of broken line segments in turn Formed, that is, bent into a multi-segment polyline segment, the starting end of the starting segment 2 in the multi-segment polyline segment is located in the center of the base 11 and connected to the installation head 1, and the end of the multi-segment polyline segment 3 The end of the segment A piercing arm 4 is formed extending toward the center of the base 11 for piercing the sealing strip.

[0042]In the above-mentioned embodiment, the installation head 1 of the spring buckle is matched with the slot on the oven box or the oven door, and the base 11 is inserted into the sealing strip. The starting end of the segment 2 is located in th...

Embodiment 2

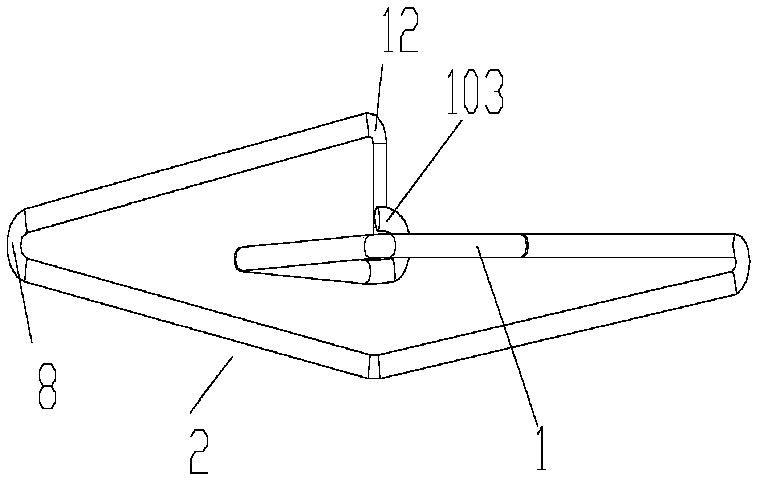

[0050] Of course, if image 3 and Figure 4 As shown, the snap buckle can be further simplified, and the diamond-shaped structure of the base 11 can be made to lack one side without affecting the practicality and performance, and the other structures are the same as the first embodiment.

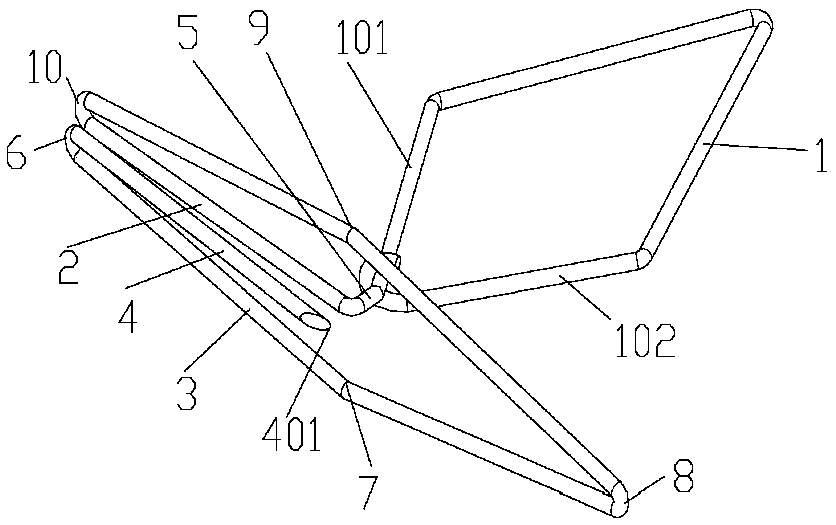

[0051] In Embodiment 1, when the spring buckle is made, the stainless steel wire starts from the piercing point 401 to form the piercing arm 4, and then encounters the first acute angle 6 and then extends to the first obtuse angle 7. When the steel wire forms the second acute angle 8, it needs to be directed to the Bend in opposite directions to form a second obtuse angle 9 and a third acute angle 10 ; tighten from the third acute angle 10 to the center point of the base 11 , and bend upward to form the connecting column 5 connected to the mounting head 1 .

[0052] In Example 2, press image 3 The shape of the base 11 as shown will keep the original diamond-shaped track, but the actual st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com