Installation method of makeshift section of buried 780mpa pressure steel pipe

A pressure steel pipe and installation method technology, applied to non-detachable pipe connections, pipes/pipe joints/pipe fittings, passing components, etc., can solve the problems of high welding residual stress, high labor intensity of workers, high installation costs, etc., and achieve welding stress And the residual stress is small, the installation period is shortened, and the effect of reducing the residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

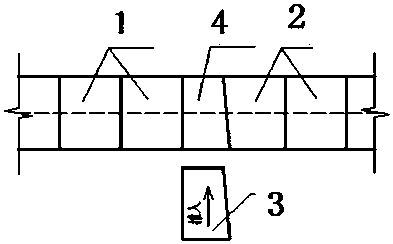

[0030] Example: The installation method of the makeshift section of buried 780MPa pressure steel pipe, such as figure 1 shown, including the following steps:

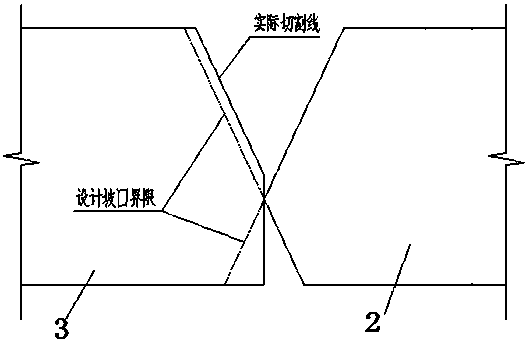

[0031] a. Make the make-up festival: Make the make-up festival into a half-eight shape;

[0032] b. Installation of upstream steel pipe and downstream steel pipe: install and fix the upstream steel pipe and downstream steel pipe of the improvised joint;

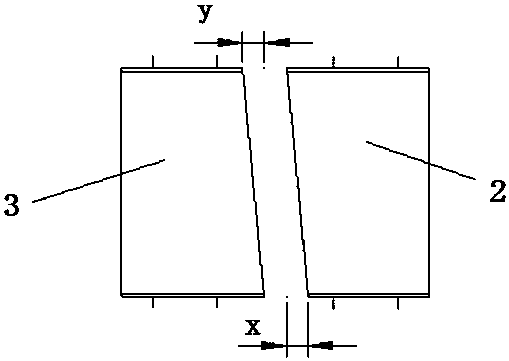

[0033] c. Fit joints in place: place the joint joints in place, and control the deviation between the joint joints and the center of the upstream and downstream nozzles ≤ 2mm;

[0034] d. Treatment of the gap between the make-up joint and the upstream and downstream steel pipes: control the clearance between the make-up joint and the upstream and downstream nozzles ≤ 2mm;

[0035] e. Crimping: control the misalignment between the improvised joint and the upstream and downstream nozzles ≤ 2mm;

[0036] f. Welding: Welding adopts segmental regression welding.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com