Electric flange connection device and operation method thereof

A technology of connection device and operation method, applied in flange connection, pipe/pipe joint/pipe fitting, transformer/inductor cooling, etc., can solve the problems of limited transformer model, difficult to fix, troublesome operation, etc. Simple and easy to implement, reduce oil leakage, and reduce maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

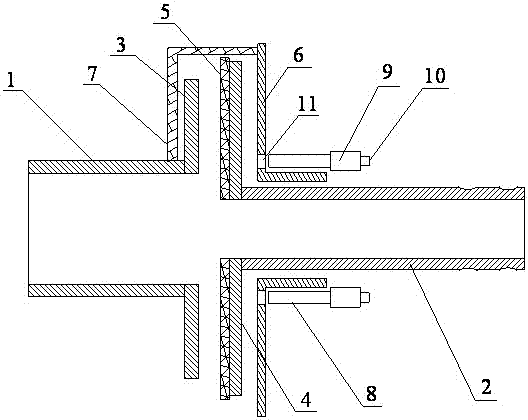

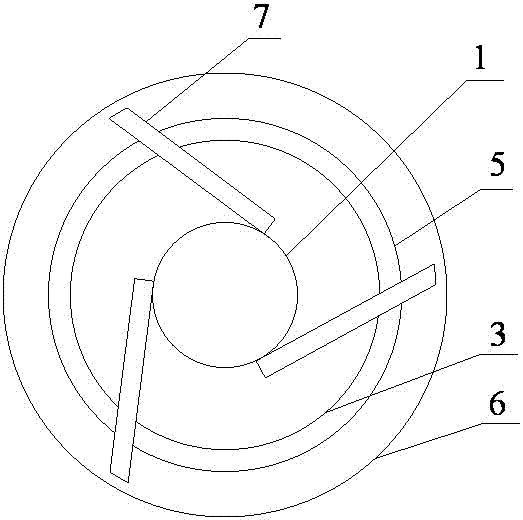

[0025] refer to figure 1 and figure 2 , an electric flange connecting device of the present invention, comprising a transformer filling and discharging oil pipe 1, oil pipe self-sealing joint 2, transformer oil filling and discharging valve flange 3, oil pipe joint flange 4, gasket 5, chuck 6, buckle 7 And the electric push rod, the flange 3 of the transformer oil discharge valve is connected with the transformer oil discharge pipe 1, the oil pipe joint flange 4 is connected with the oil pipe self-sealing joint 2, and the oil pipe joint flange 4 is set between the transformer oil discharge valve flange 3 Gasket 5, electric push rod is arranged on the outside of oil pipe self-sealing joint 2, chuck 6 is sleeved on oil pipe self-sealing joint 2, one end of chuck 6 is connected with electric push rod, and the other end is connected with several buckles 7 by hinges.

[0026] In this embodiment, the electric push rod includes a push rod 8, a motor 9 and a control device 10, and t...

Embodiment 2

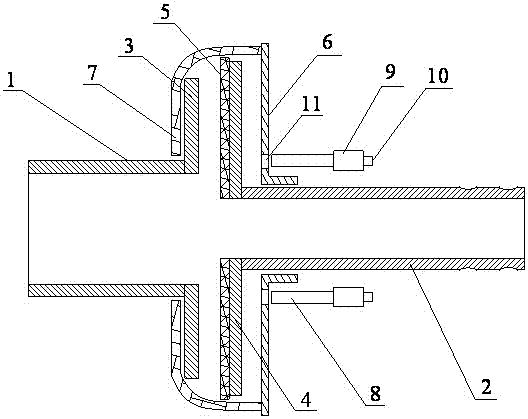

[0037] refer to image 3 and Figure 4 , an electric flange connecting device of the present invention, comprising a transformer filling and discharging oil pipe 1, oil pipe self-sealing joint 2, transformer oil filling and discharging valve flange 3, oil pipe joint flange 4, gasket 5, chuck 6, buckle 7 And the electric push rod, the flange 3 of the transformer oil discharge valve is connected with the transformer oil discharge pipe 1, the oil pipe joint flange 4 is connected with the oil pipe self-sealing joint 2, and the oil pipe joint flange 4 is set between the transformer oil discharge valve flange 3 Gasket 5, electric push rod is arranged on the outside of oil pipe self-sealing joint 2, chuck 6 is sleeved on oil pipe self-sealing joint 2, one end of chuck 6 is connected with electric push rod, and the other end is connected with several buckles 7 by hinges.

[0038] In this embodiment, the number of buckles 7 is four, and the movable connection mode of the chuck 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com