Carbon thermal rail production line and carbon thermal rail production method

A production method, carbon hot rail technology, applied in the carbon hot rail production line and production field, can solve the problems of cold air existing in the lower layer, affecting people's rest, and uneven temperature distribution, so as to ensure safety, avoid fire escape, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

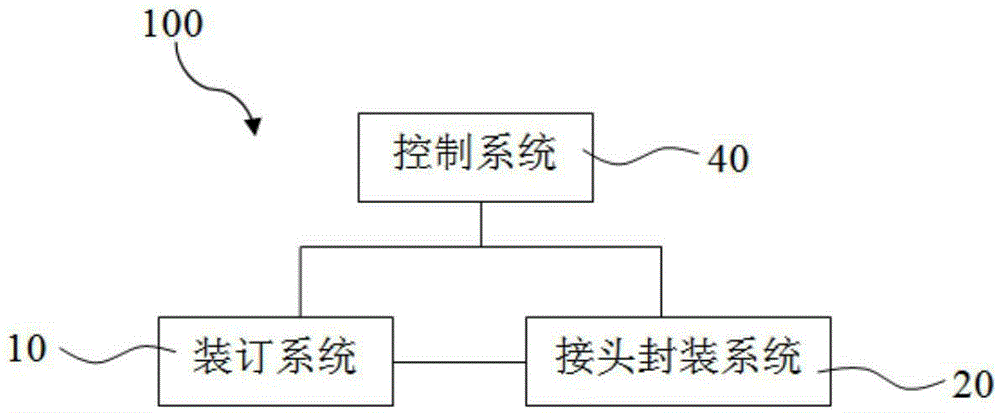

[0074] figure 2 It is a structural block diagram of a preferred embodiment of the carbon hot rail production line of the present invention, which shows the main components of a preferred embodiment of the carbon hot rail production line of the present invention.

[0075] The carbon hot rail production line 100 includes a binding system 10 , a joint packaging system 20 connected with the binding system 10 and a control system 40 connected with the binding system 10 and the joint packaging system 20 .

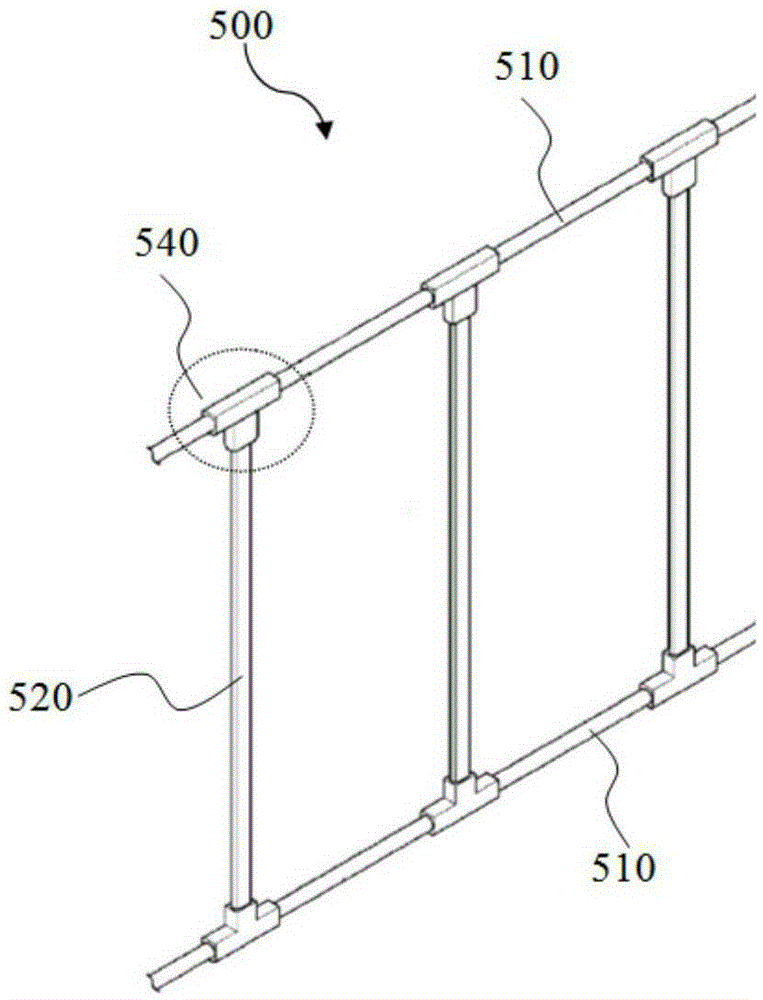

[0076] Among them, the binding system 10 is used to bind the power cord 510 and the carbon rod 520 in the carbon thermal rail 500; ; The control system 40 is used to control the binding system 10 and the joint packaging system 20 .

[0077] The carbon hot rail production line of the present invention can complete the binding and joint packaging of at least 500 carbon rods and power lines per hour, which can greatly improve the production efficiency of the carbon hot rail and re...

Embodiment 2

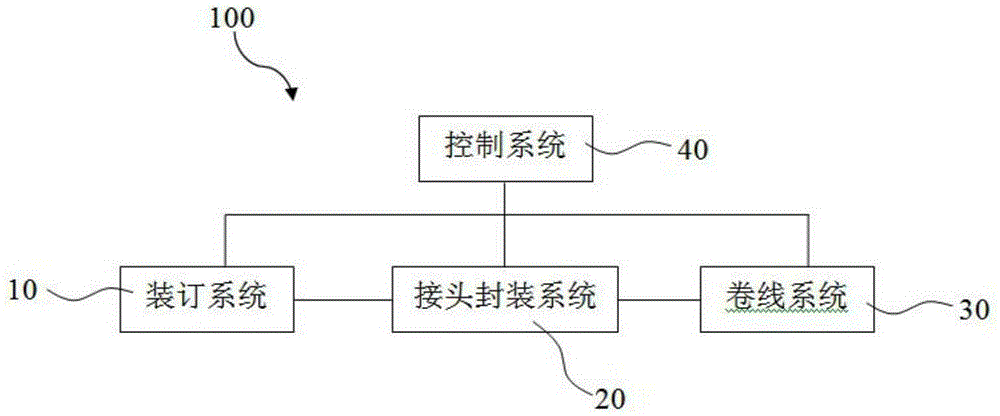

[0107] Compared with Embodiment 1, the carbon hot rail production line 100 of this embodiment also includes a winding system 30, such as figure 2 shown.

[0108] The winding system 30 is connected with the joint packaging system 20 and controlled by the control system 40, which is used for storing the finished carbon thermal rail. The winding system 30 can quickly complete the winding of the formed floor heating heat rail, improve the packaging efficiency of the carbon heat rail, and reduce the cost.

[0109] The carbon rods and power cords that have been packaged with joints are transported to the winding system 30 through the second feeding mechanism 230 .

[0110] Preferably, the winding system 30 is a winding machine.

[0111] preferred, such as Figure 12 As shown, the winding system 30 includes a winding reel 310 driven by a motor and a counting sensor 340 connected to the control system 40 . The winding system 30 is disposed on the third supporting platform 320 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com