A blast hole distribution instrument

A technology of hole layout instrument and blast hole, which is applied in blasting and other directions, which can solve the problems of inaccurate hole network parameters and low hole layout efficiency, and achieve the effects of easy instrument production, high positioning accuracy, and quick and simple on-site debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

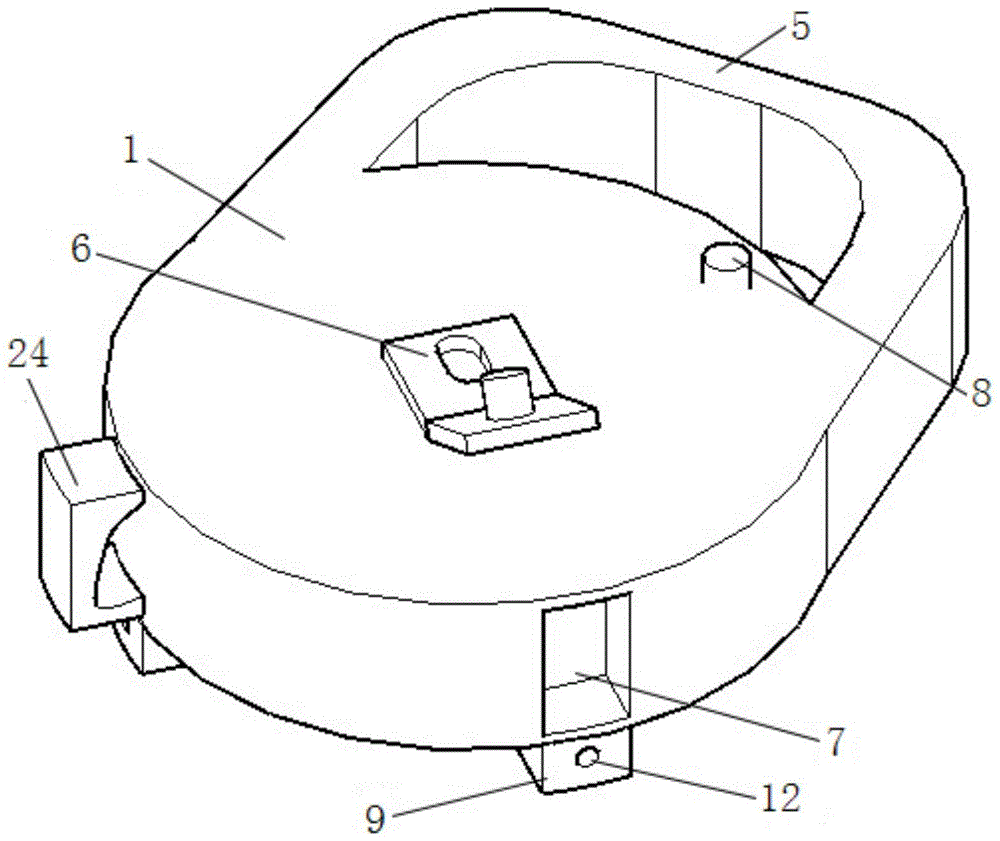

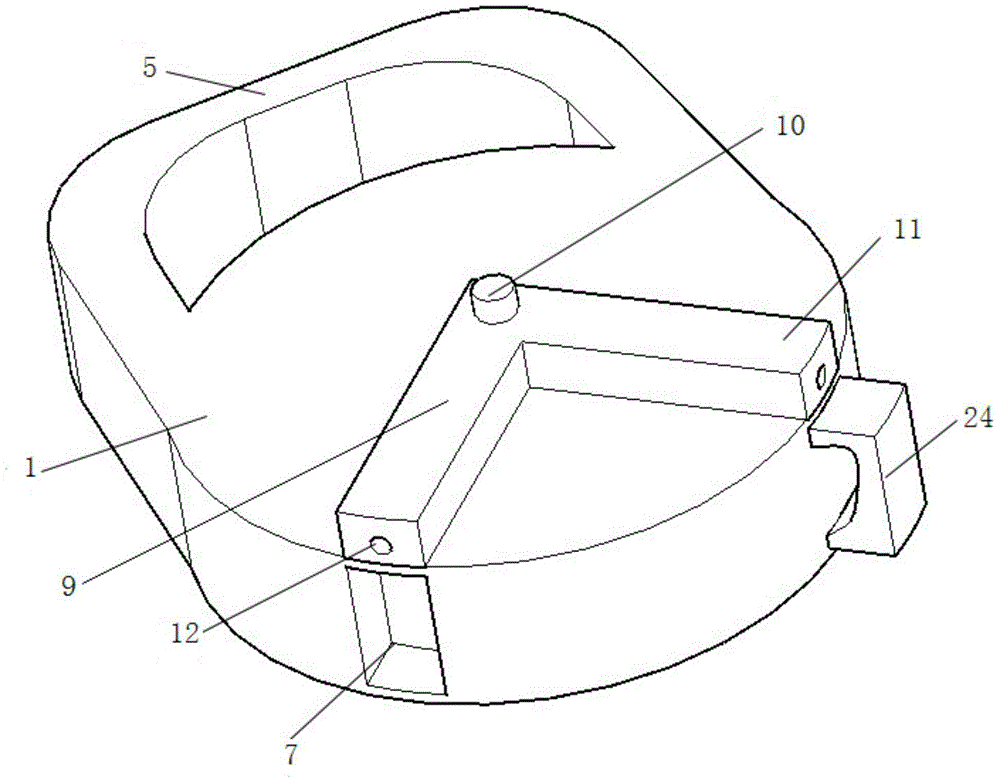

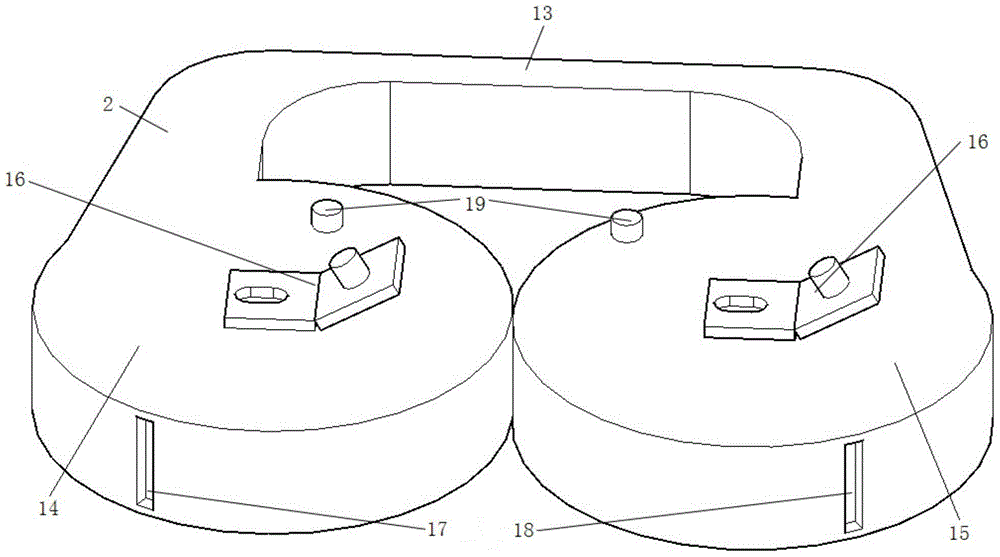

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a hole-distributing instrument for blastholes comprises a single plate 1 of a hole-distributing instrument, a double plate 2 of a hole-distributing instrument, a pull ring 3 of a hole-distributing instrument, and a tape measure 4. Tape tape rocker 6, single tape tape outlet 7, single disc brake button 8, right-angle laser directional gun 9, right-angle laser directional gun 9 includes laser switch button 10 and two laser directional guns 11 at right angles to each other, each laser Orientation gun 11 ends are provided with laser emitting head 12, and cloth hole instrument double disk 2 comprises double disk hand-held part 13 and two sets of tape measure devices, and every cover of tape measure device comprises double disk tape measure rocking bar 16, double disk tape measure outlet, double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com