Foodstuff purifying system with high-efficiency

A food purification and high-efficiency technology, applied in food preparation, food science, chemical instruments and methods, etc., can solve the problems of poor purification performance and environmental protection effect, and achieve the effects of low maintenance cost, strong sterilization, and long validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

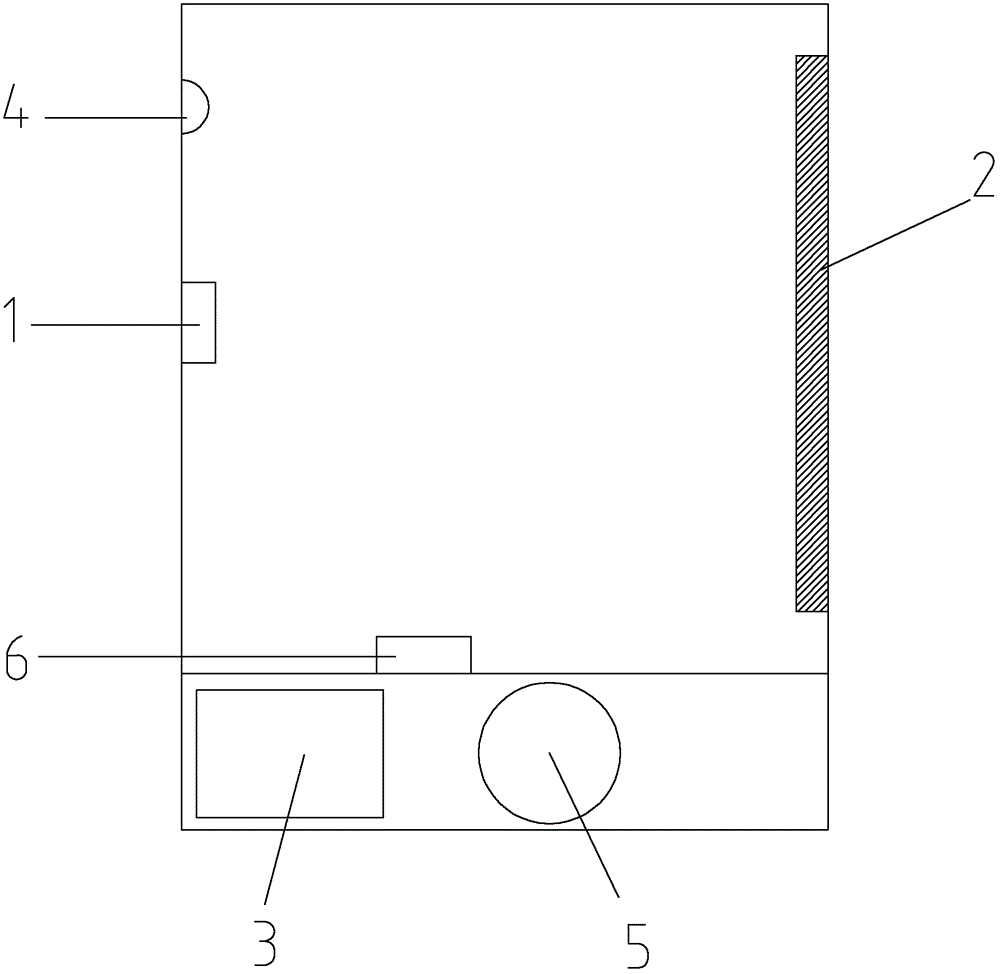

[0010] exist figure 1 Among them, 1 is a water catalyst; 2 is a photocatalyst; 3 is an electrolytic water generator; 4 is a fluorescent light source; 5 is a water pump; 6 is an ultrasonic transducer. A high-efficiency food purification system, characterized in that it includes a cleaning tank, a water pump, an electrolyzed water generator, an ultrasonic system, a water catalyst, and a photocatalyst; the electrolyzed water generator, the cleaning tank and the water pump are all provided with a water inlet and a water outlet, The electrolytic water generator, cleaning water tank and water pump are connected into a closed loop through pipelines; the cleaning water tank is equipped with an ultrasonic system, water catalyst, and photocatalyst; the water catalyst is titanium dioxide and stainless steel; the photocatalyst is nano-titanium dioxide coating, which is evenly sprayed on the cleaning water tank The surface is provided with a fluorescent light source; the nano-titanium diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com