Steel tube pressure test sealing apparatus and pressure test apparatus therewith for pressure test on multiple tubes

A sealing device and pressure testing technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of multiple screw rods setting costs and large waste of functions, many non-working hours, and structure Insufficient compactness and other problems, to achieve the effect of convenient adjustment, high efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

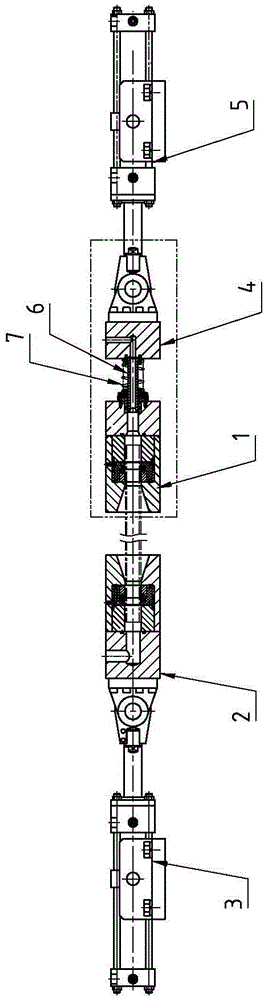

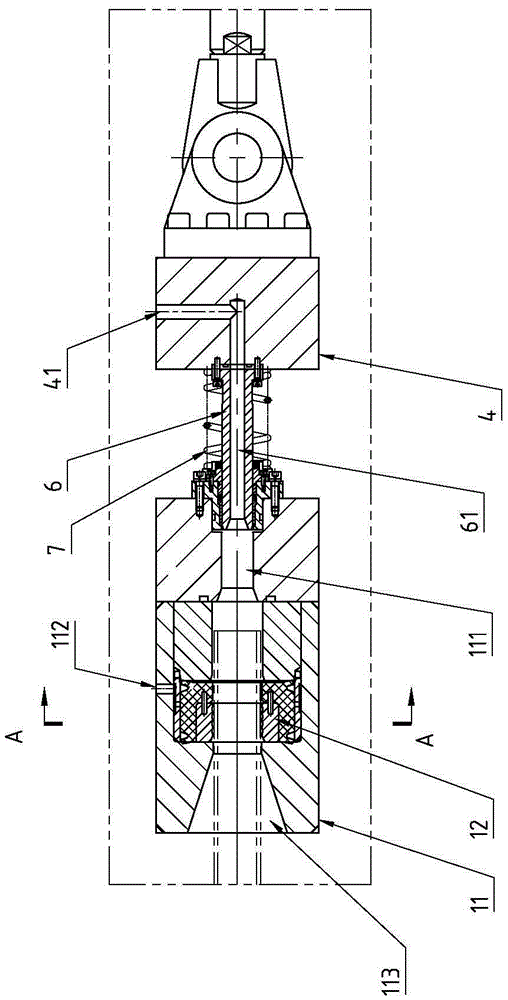

[0028] Embodiment 1 is an embodiment of the steel pipe pressure test sealing device involved in the present invention. figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 illustrate.

[0029] figure 1 In the middle, the first sealing head 1 is located on the right side, and the second sealing head 2 is located on the left side. The rear of the sealing head 1 is connected with the adjusting seat 4 by a piston 6 , the driving cylinder 5 is connected with the adjusting seat 4 , and the rear of the second sealing head 2 is connected with the driving cylinder 3 .

[0030] To make figure 1 The structure representation of the first sealing head and the adjustment seat in the image 3 for figure 1 Enlarged view of the double-dot dash line part; image 3 Among them, the first sealing head 1 includes a sealing seat 11 and a sealing ring 12, the sealing ring 12 is installed in the sealing seat 11, the sealing seat 11 is provided with a pipe end penetration hole 113, and the ...

Embodiment approach 2

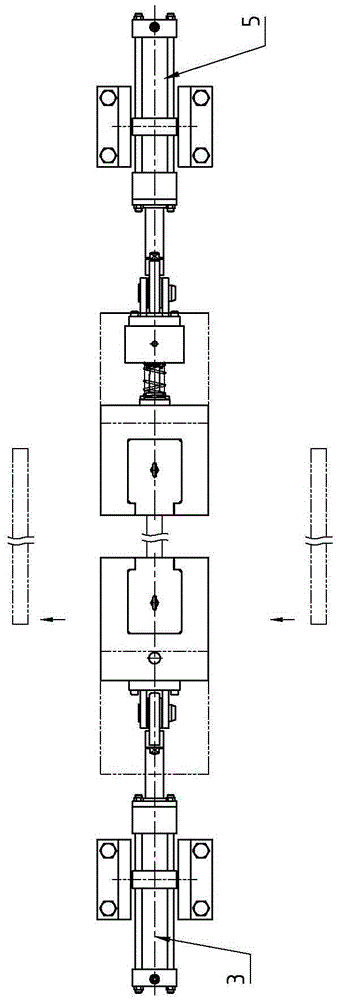

[0038] Embodiment 2 is an embodiment of the pressure test device for multi-pipe pressure test using the steel pipe pressure test sealing device involved in the present invention. Image 6 , Figure 7 illustrate.

[0039] Image 6 The middle is a top view of a pressure test device that can test the pressure of 4 steel pipes. In the figure, 4 sets of pipe end pressure test sealing devices identical to Embodiment 1 are arranged in parallel, and 4 steel pipes of different lengths are tested simultaneously, and one steel pipe corresponds to a set of pipe end pressure test sealing devices; Image 6 As shown, the lower two steel pipes are longer, and the corresponding two sets of first sealing heads have a larger retreat range. The adjustment seat is relatively fixed, the first sealing head can move back and forth freely, the steel pipe is longer, and the range of retreat is larger, and the steel pipe is shorter, and the range of piston retreat is smaller, so as to realize the ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com