Combustion particle multi-parameter measurement device and method adopting blue-ray back lighting

A technology of backlighting and measuring devices, which is applied in measuring devices, particle suspension analysis, fluid velocity measurement, etc., can solve the problems of flame self-illumination and mutual interference between lighting backlights, avoid the influence of burning flames, and enrich measurement parameters , and deepen the effect of measurement parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

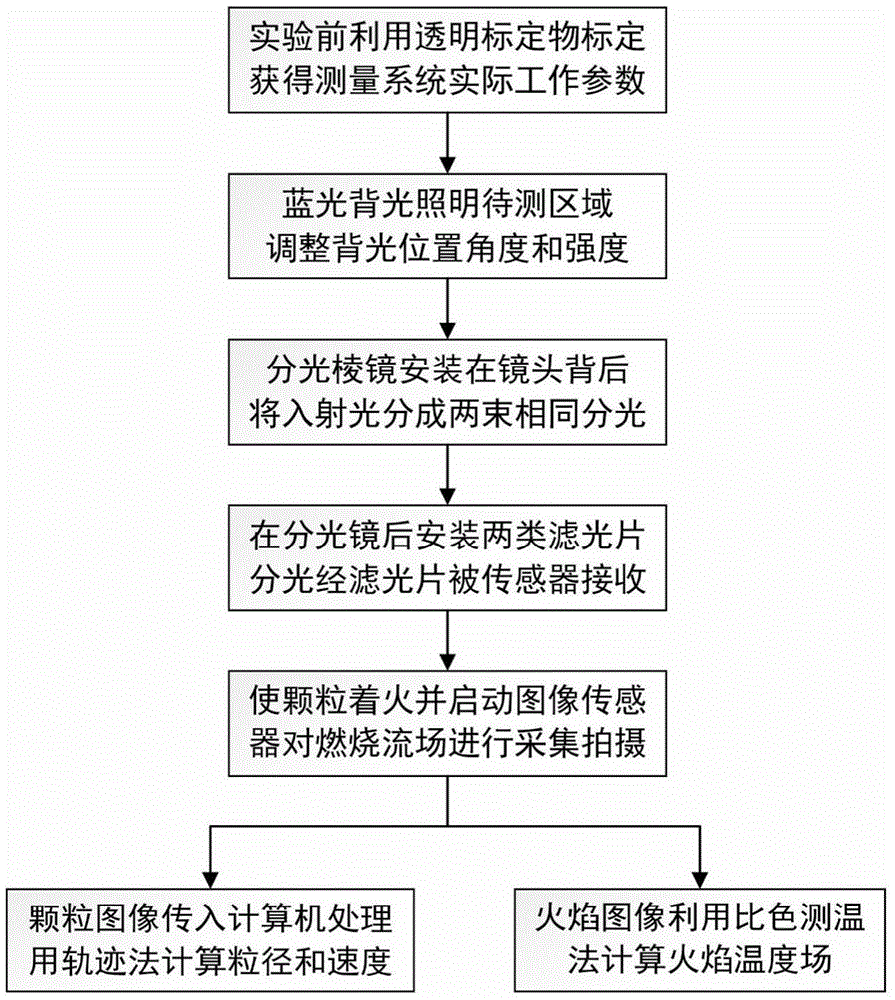

Method used

Image

Examples

Embodiment 1

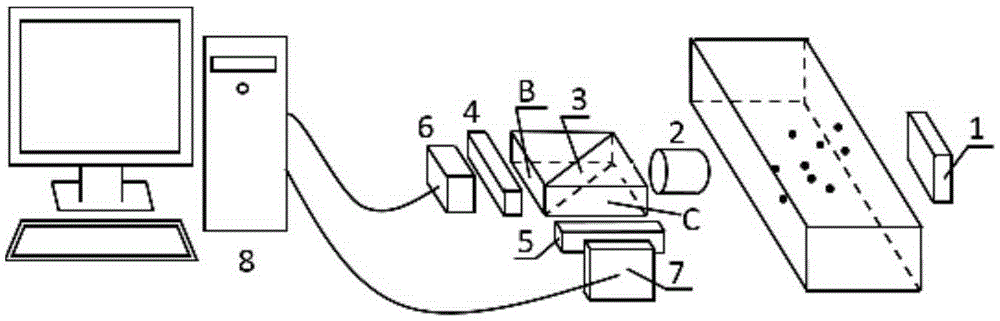

[0040] Such as figure 2 As shown, the device includes a blue light source 1, a camera composed of a lens 2, a beam splitter 3, a blue light bandpass filter 4, a blue light cut filter 5, a first image sensor 6, and a second image sensor 7. And computer 8; Illumination area 11 to be measured with blue light source 1 in the mode of backlight, dichroic prism 3 is installed on the back of first lens 2, and first lens 2 receives the light beam that blue light source 1 emits and measured particle scattering in area 11 to be measured The beam splitter 3 divides the light entering the first lens 2 into two beams with the same spectral composition and intensity. One beam is filtered by the blue light bandpass filter 4 and then received by the first image sensor 6, and the other beam is filtered by the first image sensor 6. After being filtered by the blue light cut filter 5, it is received by the second image sensor 7, and the first image sensor 6 and the second image sensor 7 convert ...

Embodiment 2

[0058] The blue light band-pass filter 4 and the blue light cut-off filter 5 among the embodiment 1 are plated on the surface of the first exit surface B and the second exit surface C of the beam splitter 3 in a film mode, as image 3 As shown, the beam splitter 3, the blue light bandpass filter 4 and the blue light cut filter 5 in the first embodiment constitute a whole, and the steps of the measurement method are the same as those in the first embodiment.

Embodiment 3

[0060] The blue light bandpass filter 4 and the blue light cut filter 5 in Embodiment 1 are screwed into the camera, that is, fixed in front of the first image sensor 6 and the second image sensor 7, as Figure 4 As shown, the measurement method steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com