Array substrate, driving method, organic light-emitting display panel, and display device

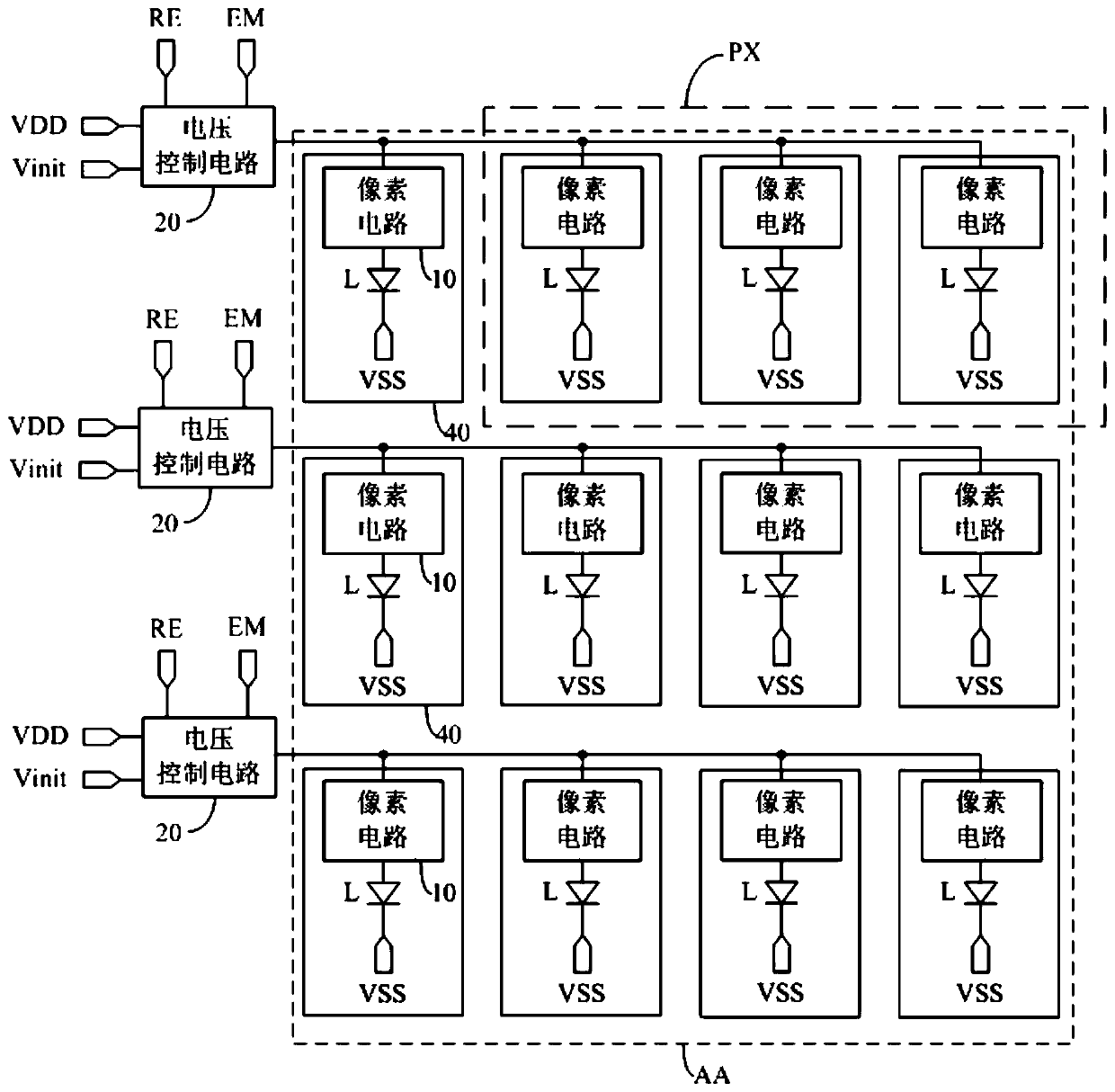

A technology for array substrates and display areas, applied to static indicators, instruments, semiconductor devices, etc., can solve problems such as unfavorable OLED display panels, achieve the effects of simplifying the structure, reducing the occupied area, and improving the afterimage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

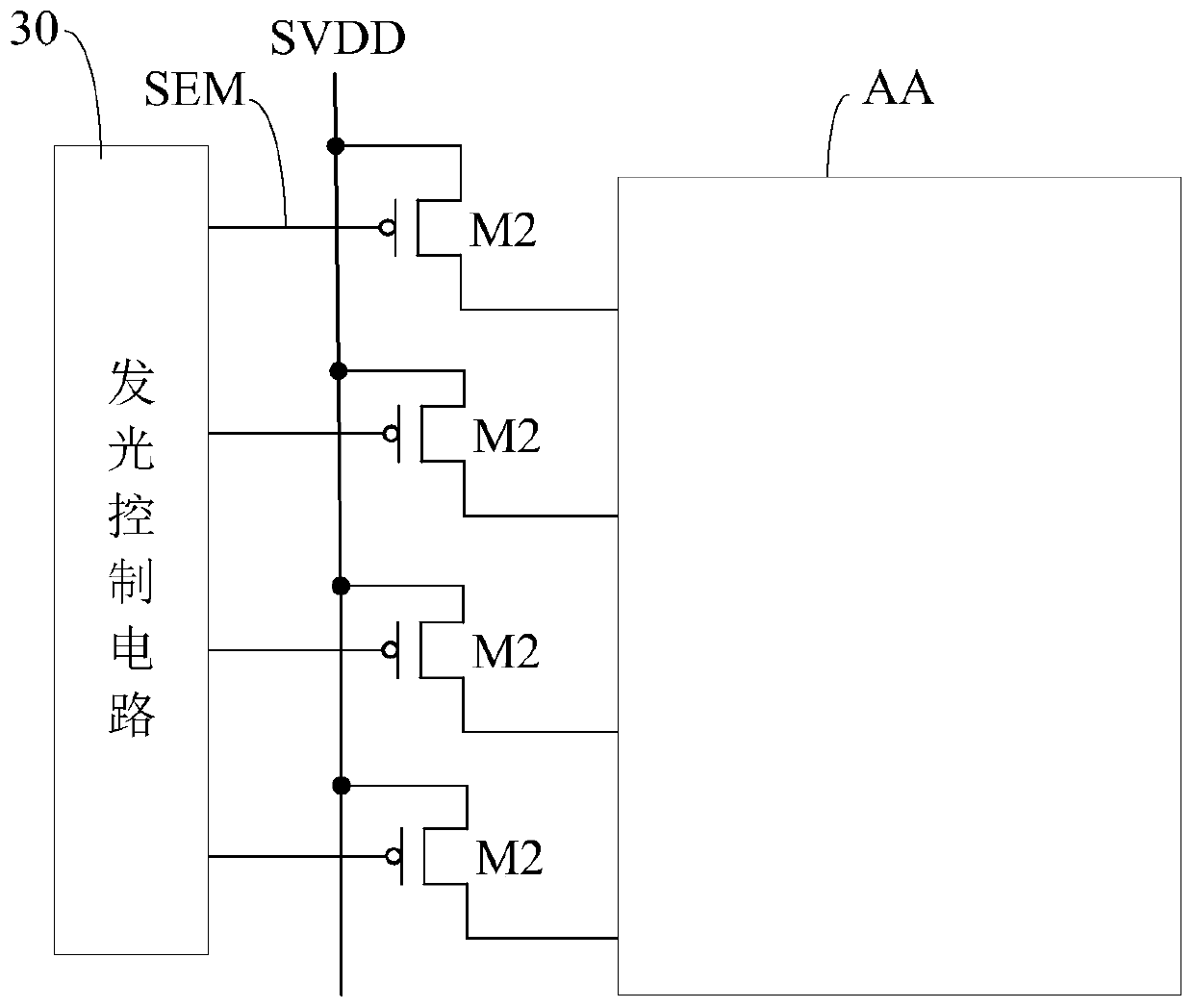

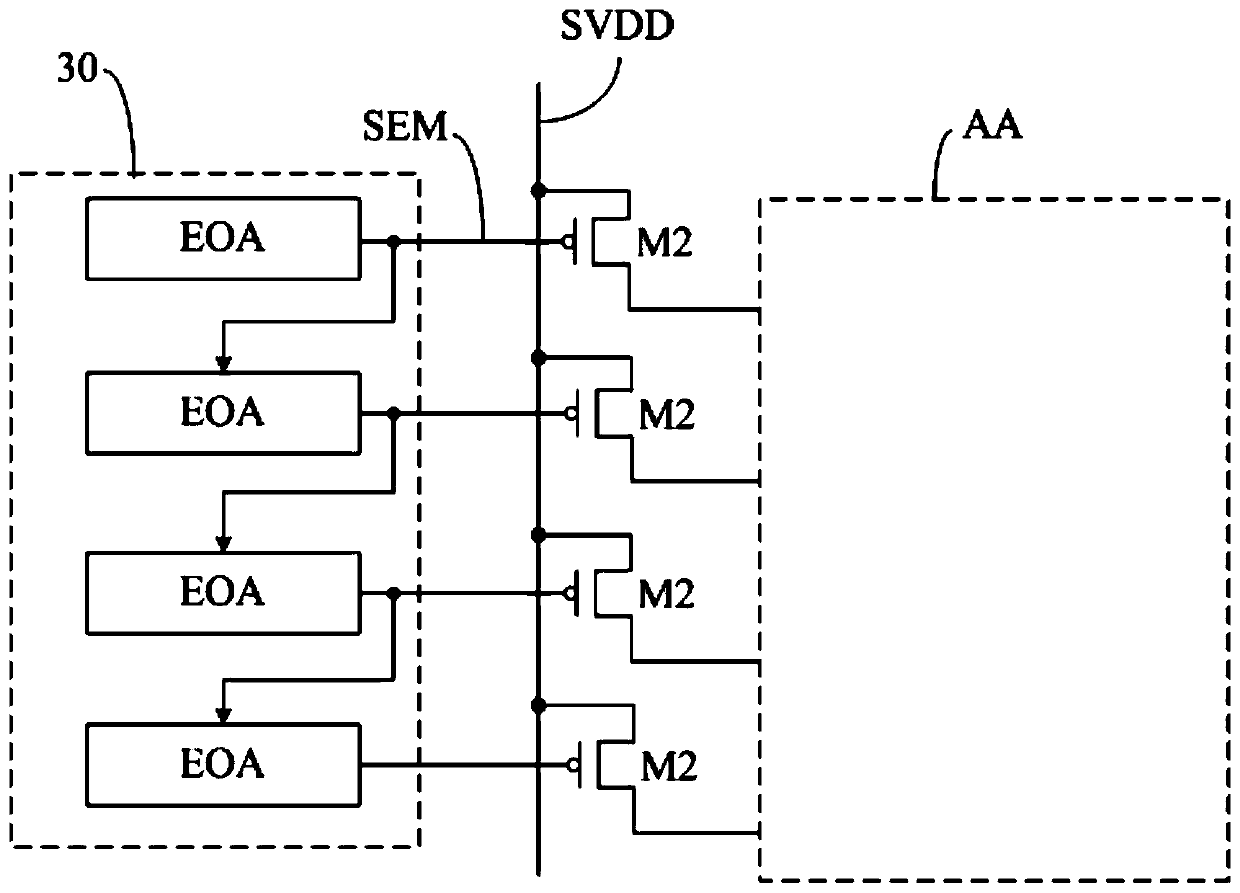

Method used

Image

Examples

Embodiment 1

[0080] by Figure 4 The array substrate shown is taken as an example, and the corresponding circuit timing diagram is as follows Figure 7 shown. Driving a row of light emitting devices to work may include: a reset phase T1, a data writing phase T2, and a light emitting phase T3.

[0081] In the reset phase T1, S1=0, S2=1, RE=1, EM=1.

[0082] Since EM=1, the second switching transistor M2 is turned off. Since S1=0, the third switching transistor M3 is turned off. Since S2=1, the fourth switching transistor M4 is turned off. Since RE=1, the first switching transistor M1 is turned on to provide the initialization signal Vinit to the first pole S of the driving transistor M0. It should be noted that, if the previous frame is displayed, the gate G of the driving transistor M0 stores a high-grayscale data signal (that is, displays a high grayscale) through the storage capacitor Cst, then the first electrode S, The voltages of the second pole D and the positive pole of the li...

Embodiment 2

[0088] The schematic diagram of the structure of the array substrate corresponding to this embodiment is as follows: Figure 4 As shown, it is modified for the implementation in the first embodiment. The following only describes the differences between this embodiment and the first embodiment, and the similarities will not be repeated here. In specific implementation, such as Figure 8 As shown, after the light-emitting period T3, driving a row of light-emitting devices to work may also include: a non-light-emitting period T4; wherein, in the non-light-emitting period T4, the voltage control circuit responds to the light-emitting control signal EM, and combines the first power signal with the driving transistor. The first pole is turned off, and the corresponding pixel circuit is controlled to drive the connected light emitting device to stop emitting light.

[0089] Specifically, the corresponding circuit timing diagram is as follows Figure 8 shown. Driving a row of ligh...

Embodiment 3

[0092] In specific implementation, such as Figure 9 As shown, within one frame display time Frame, the non-light-emitting phase T4 driving each row of light-emitting devices can be turned on at the same time t0.

[0093] Specifically, a general array substrate may include K rows of pixel units, where K is a positive integer. Gate_k (1 ≤ k ≤ K, and an integer) represents signals for driving the pixel circuit in the pixel unit in the k-th row. Within a frame display time Frame, the pixel circuit can be driven to work by row-by-row driving, and after the light-emitting devices in the first row of pixel units to the last row of pixel units are driven to emit light, then the light-emitting devices in each row of pixel units are controlled simultaneously Stop glowing. For example, when the display time Frame of one frame is 11.1 ms, the non-light-emitting period T4 can be occupied for 2 ms, and the remaining 9.1 ms is the time for driving the pixel circuits in the first row to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com