Intelligent recommendation method for stacking position of steel coil storeroom

A recommended method, steel coil technology, applied in the field of control and scheduling, and warehouse management, can solve the problems of frequent stacking times, disorderly stacking of steel coil warehouses, and large area, so as to reduce the index of stacking confusion and reduce the chaos of warehouses , the effect of reducing the number of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

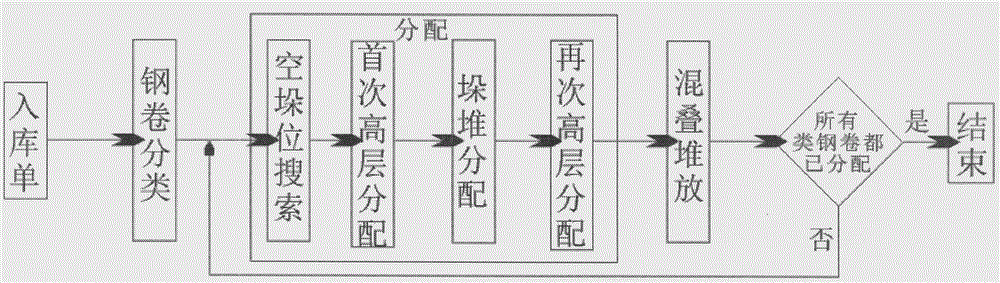

[0029] like figure 1 As shown, a method for intelligently recommending storage stacks in a steel coil warehouse, the method mainly includes the following steps:

[0030] 1) Classification of storage receipts. The classification rules for storage receipts need to be carried out according to the actual warehouse. Different warehouses usually have different classification rules. The inventory list is as follows:

[0031] Coil No.

steel type

width

weight

Coil type

other attributes

3528AY133P

TXHC

1250

20.19

Flat Outer Curls

3528CY077P

TXHC

1250

21.05

finished hair curl

3530AE1731

SPHT-DF

1219

10.54

Flat sub-volume

3529CE0011

A36

1500

11.26

Flat Outer Curls

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com