Metal connector enabling a lead to be detachable after the lead is inserted into the metal connector

A metal connector and wire technology, applied in the direction of connection, fixed connection, and parts of the connection device, etc., can solve the problems of difficult to pull out the wire, large amount of material, complex structure, etc., to achieve convenient installation and fixation, reduced material consumption, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

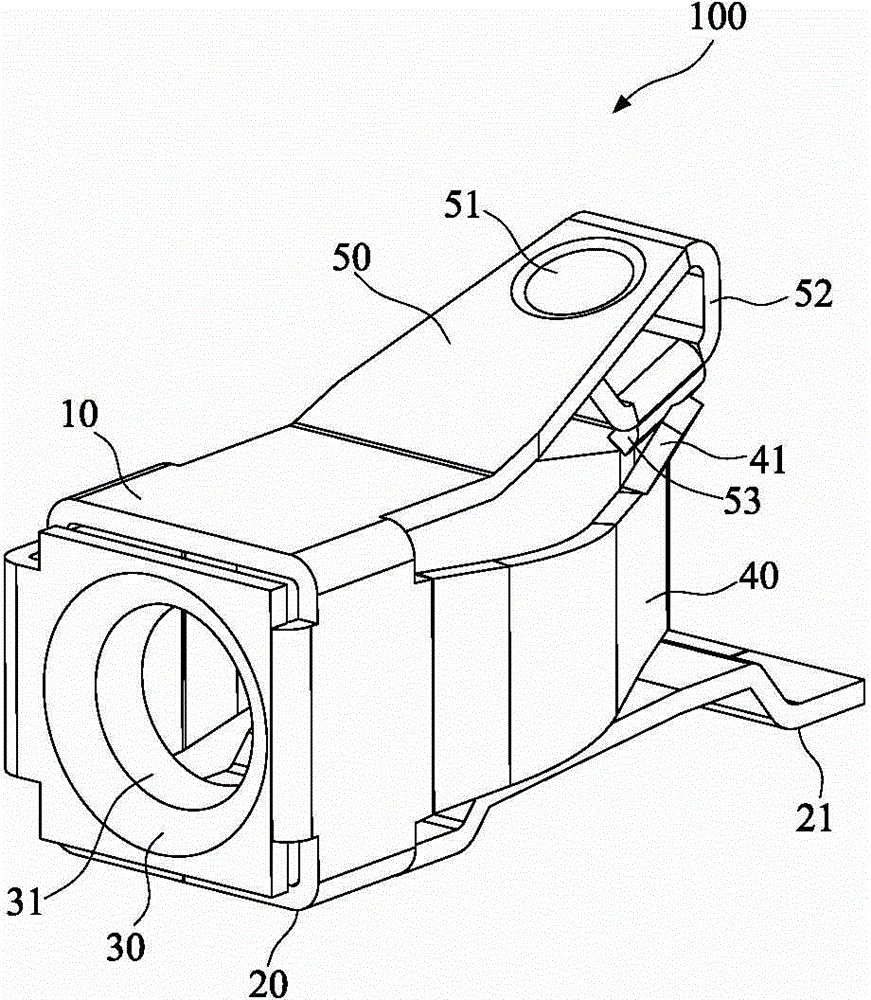

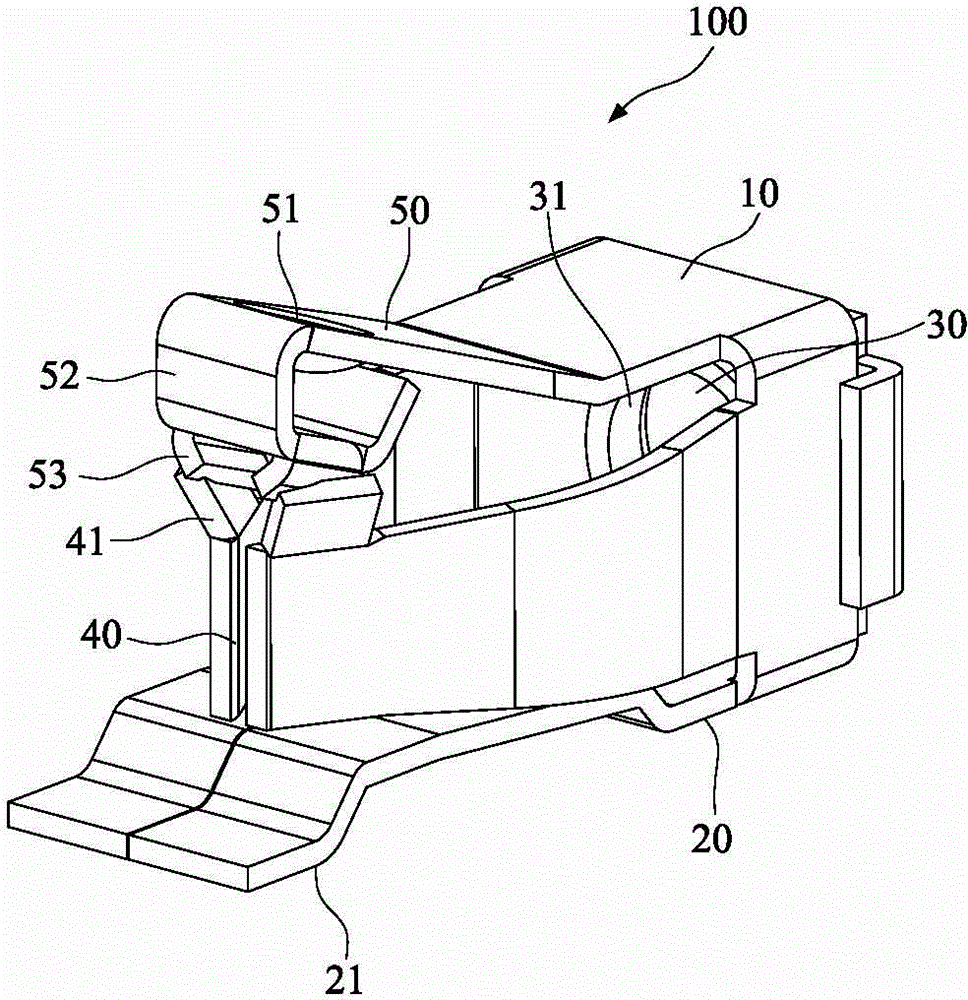

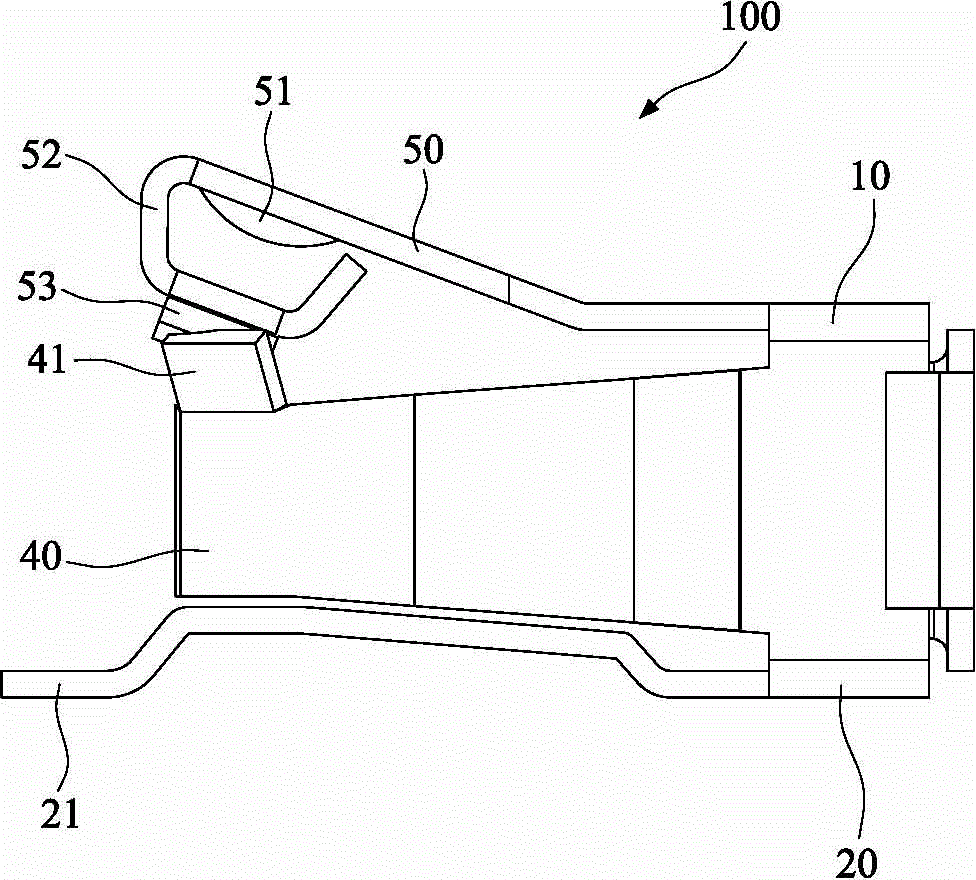

[0026] Such as Figure 1 to Figure 7 As shown, the openable metal connector 100 for wire insertion disclosed by the present invention has a base 10, and the base 10 in this embodiment is in the shape of a square cylinder.

[0027] A soldering surface 20 is formed on the bottom of the base 10 . In order to make the installation more secure, the rear bottom edge of the base 10 extends the weld reinforcement surface 21 .

[0028] A wire insertion port 30 is formed in front of the base 10 . In order to facilitate the insertion of the wire 200 , a chamfered surface 31 is formed on the wire insertion opening 30 at the front of the base 10 .

[0029] Two sides at the rear of the base 10 are relatively bent to form an elastic clip 40 , and a top edge of the elastic clip 40 forms an upwardly flared bell mouth 41 .

[0030] The rear top edge of the base 10 is bent upwards to form an elastic piece 50 , the elastic piece 50 is located above the bell mouth 41 , and the elastic clip 40 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com