Equipment for making sandwich biscuits

A sandwich biscuit and equipment technology, applied in the field of sandwich biscuit production equipment, can solve problems such as separation, sandwich biscuit splitting, and lower quality of sandwich biscuits, so as to achieve the effects of improving flexibility, improving efficiency, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

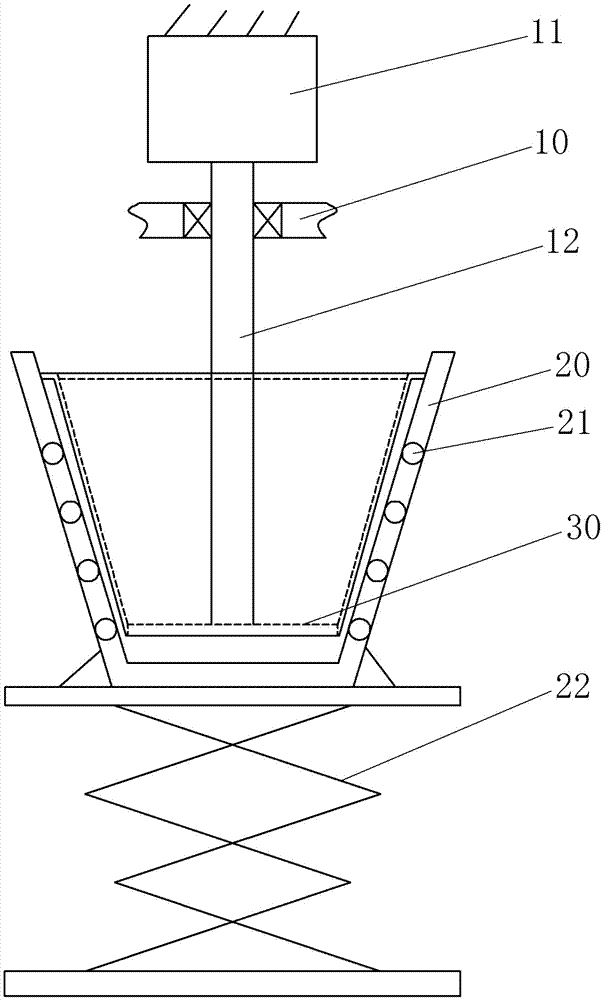

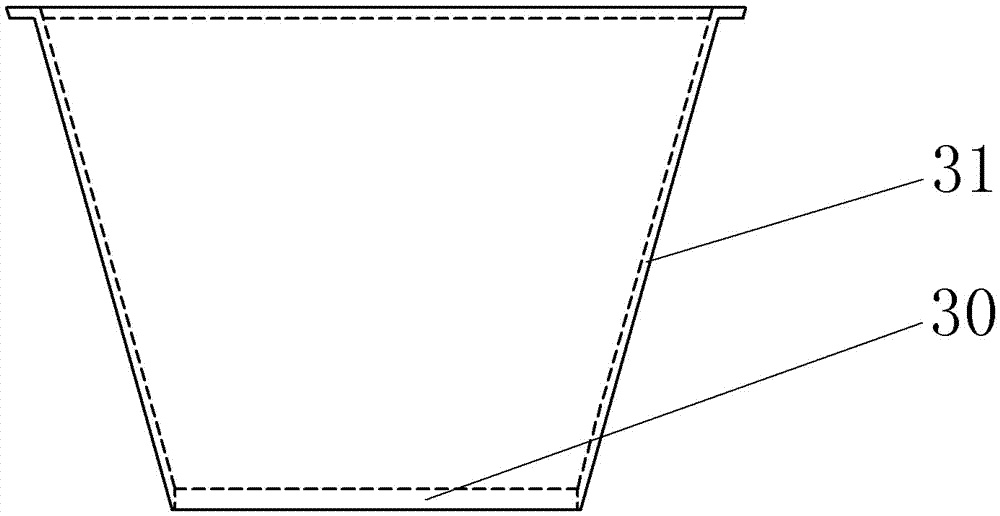

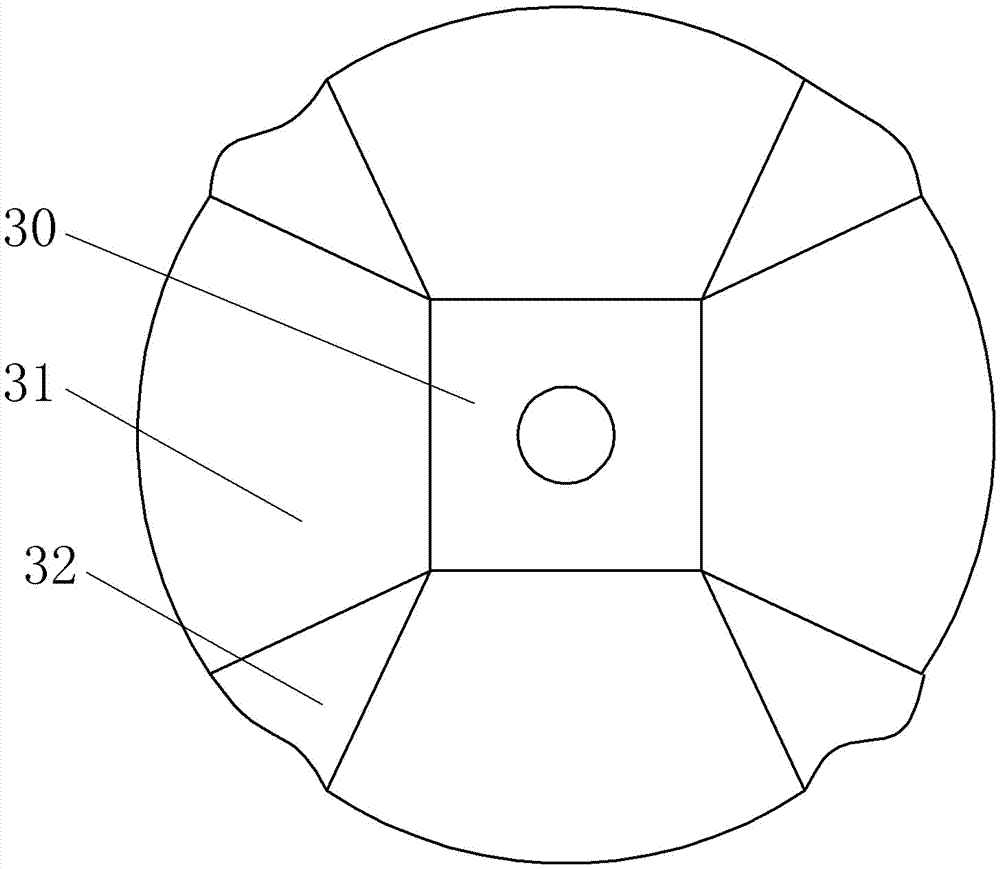

[0021] The reference signs in the accompanying drawings include: frame 10 , driving device 11 , rotating shaft 12 , heating barrel 20 , coil 21 , hydraulic lifting platform 22 , fixing plate 30 , sieve plate 31 , and flexible connecting cloth 32 .

[0022] The embodiment is basically shown in 1-3: the sandwich biscuit making equipment includes a frame, and also includes a driving device, a rotating shaft, a bearing, a screening device, a heating barrel made of stainless steel and Hydraulic lifting platform, the heating barrel is welded on the upper end of the hydraulic lifting platform through angle steel. The heating barrel is in the shape of an inverted cone and its inner wall is embedded with a coil. And the driven bevel gear fixed on the upper end of the rotating shaft. The rotating shaft is connected to the frame through bearings. The screening device includes a siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com