Automatic-control constant-speed descending device

A uniform-speed descending, center-axis technology, applied in life-saving equipment, building rescue, etc., can solve the problems of narrow audience, large limitations, secondary injuries of escape personnel, etc., and achieve low production and processing costs and low manufacturing costs. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

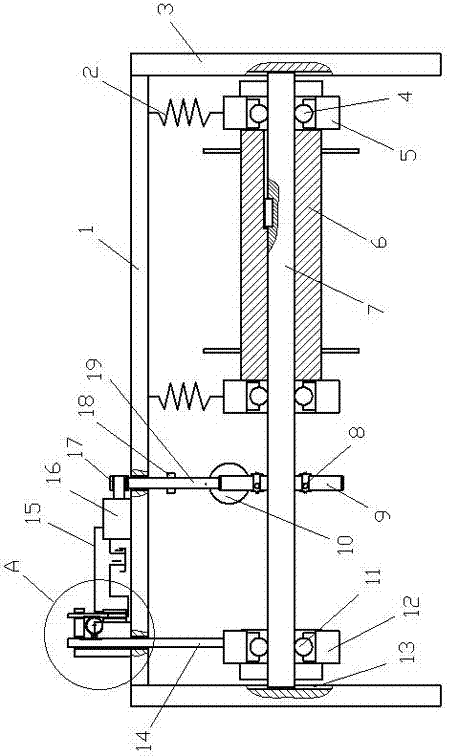

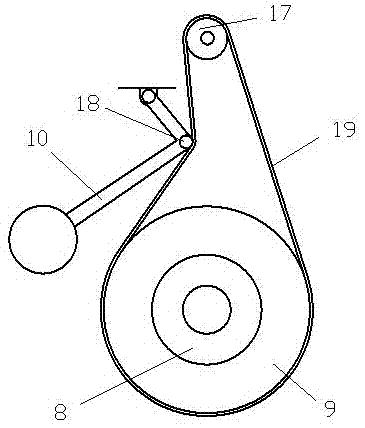

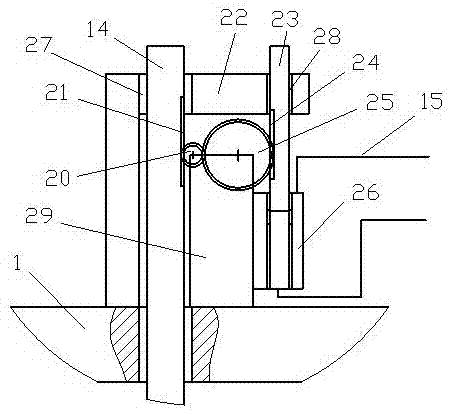

[0029] refer to Figure 1 to Figure 4 , a kind of automatic control constant-speed descending device provided by the present invention, the reel 6 is suspended on the cross bar 1 of the fixed frame through the elastic force mechanism installed on its central axis 7, and two groups of elastic force mechanisms are respectively installed on both sides of the reel, The two ends of the central shaft 7 extend into the chute 13 of the two columns 3 of the fixed frame respectively. When the reel 6 is subjected to a gravity load, the reel can rotate with the central shaft 7 relative to the elastic mechanism and slide down along the chute 13 to pull Stretching the elastic force mechanism, it is provided that when the elastic force mechanism is stretched larger, the resistance torque applied to the central axis 7 is larger and when the elastic force mechanism is stretched smaller, the resistance torque applied to the central axis 7 is less so that it can maintain The hydraulic damping me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com