Steel wire mesh rack plate locating supporting part, and wall body and construction technology thereof

A technology of steel mesh frame and positioning support, which is applied to walls, building components, thermal insulation and other directions, can solve problems such as the displacement of the protective layer of the steel mesh frame plate, achieve low preparation and processing costs, overcome cold and hot bridges, and simple and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

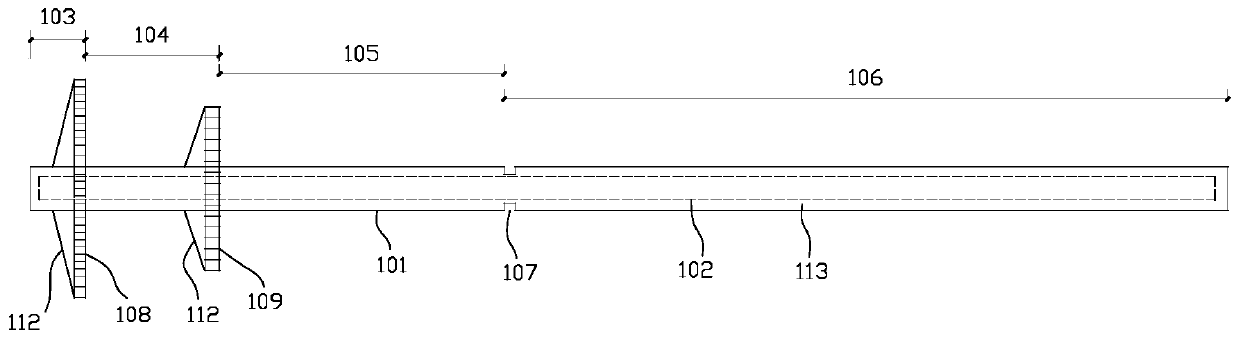

[0047] Figure 1-3As shown, this embodiment discloses a steel wire grid plate positioning support, which is used for positioning the steel wire grid insulation board during the construction of the steel wire grid insulation board, and the steel wire grid insulation board includes a central insulation board 201 and a steel wire mesh Sheet 204, the two sides of the insulation board 201 have a first pouring layer and a second pouring layer for cast-in-place. The second pouring layer is the space where the shear wall is located.

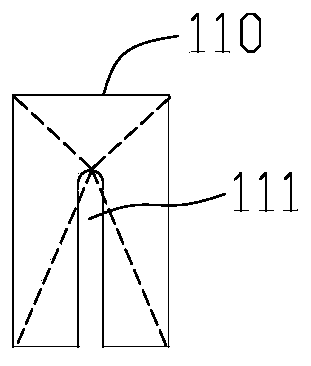

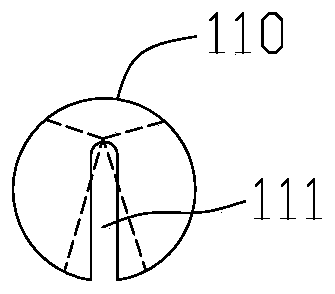

[0048] The wire mesh frame plate positioning support of this embodiment includes a support rod 101, a first support 108, a second support 109 and a third support 110, wherein the support rod 101, the first support 108 and the second support 109 It is made of integral molding of plastic material. If the supporting rod 101 is made of steel bars and causes thermal and thermal bridge problems, the thermal and thermal bridge effect can be avoided by using p...

Embodiment 2

[0054] like Figure 4 As shown, this embodiment discloses a wall body.

[0055] it includes:

[0056] At least one steel wire grid insulation board, the steel wire grid insulation board includes a insulation board 201 and a steel wire mesh sheet 204, the two sides of the insulation board 201 have a first pouring layer and a second pouring layer, and there is a shear force in the second pouring layer wall reinforcement;

[0057] At least one wire mesh frame plate positioning support in Embodiment 1, the support rod 101 passes through the insulation board 201, wherein the first support section 103 is located on the left side of the steel mesh sheet 204, and the first support 108 leans against the steel mesh sheet 204 The left side of the steel mesh sheet 204 is used to limit the outward displacement of the steel mesh sheet 204. The second support section 104 is located between the steel mesh sheet 204 and the insulation board 201, and the second support 109 is used to limit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com