Vertical hole grouting composite self-heat preservation building block

A technology for self-insulating blocks and blocks, applied in building materials, building components, buildings, etc., can solve the problems of low stability of layout, insufficient structural strength of blocks, low bonding stability, etc., and achieve stable layout. , the effect of enhancing structural strength and reducing its own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

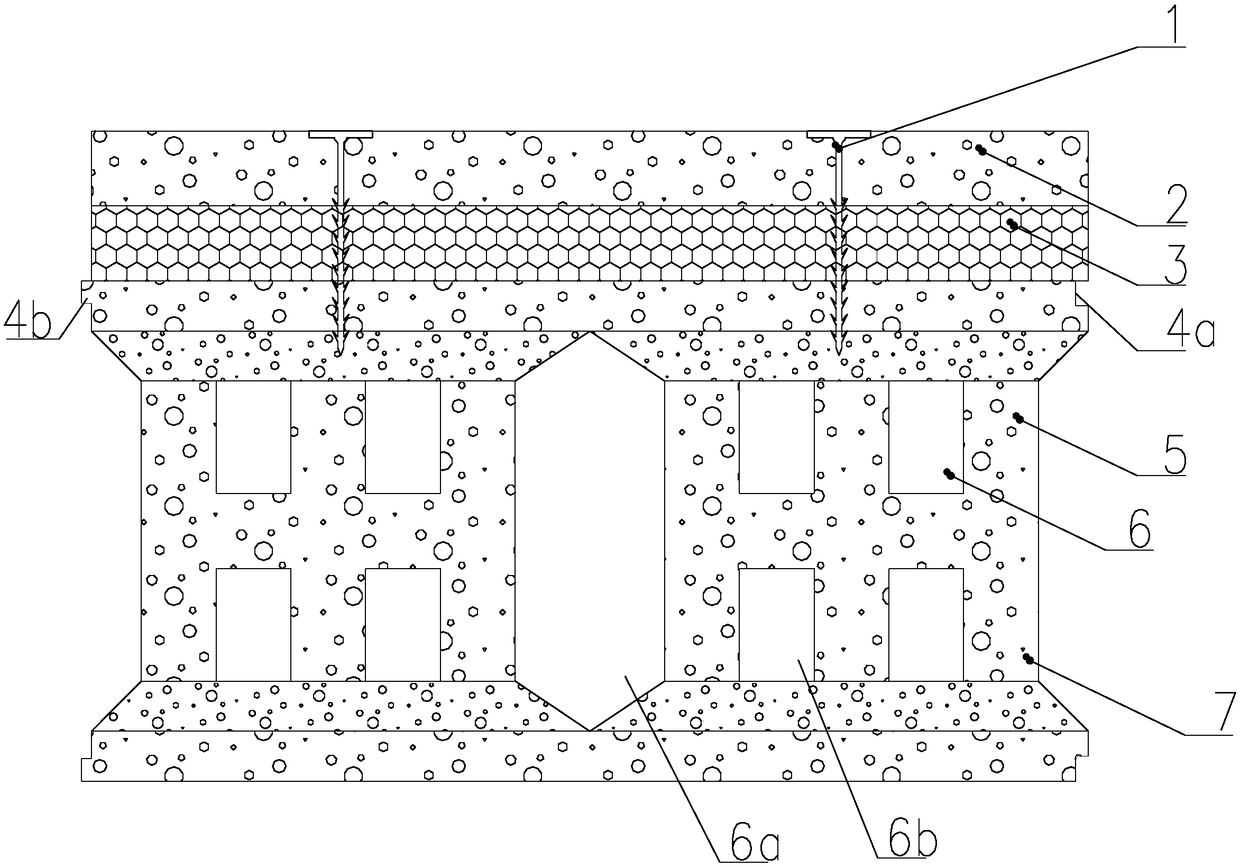

[0035] refer to figure 1 , 5 , the first embodiment of the present invention: a vertical hole grouting composite self-insulating block, including block outer pages 2, insulation layers 3, block inner pages 5, block outer pages 2 arranged in sequence from outside to inside , insulation layer 3, and block inner pages 5 are fixedly connected by anchor bolts 1, and the upper end surface of the block inner pages 5 is provided with accommodating grooves 7; the left and right sides of the block inner pages 5 are provided with grooves , the grooves on both sides have the same groove shape and are arranged symmetrically, and a vertical cavity 6 is provided through the block inner page 5 along the up and down direction of the block inner page 5 . The vertical cavity 6 includes a plurality of cavities located on the inner page 5 of the block, and the plurality of cavities include a symmetrical cavity 6a located in the middle of the inner page 5 of the block and a cavity located on both ...

no. 2 example

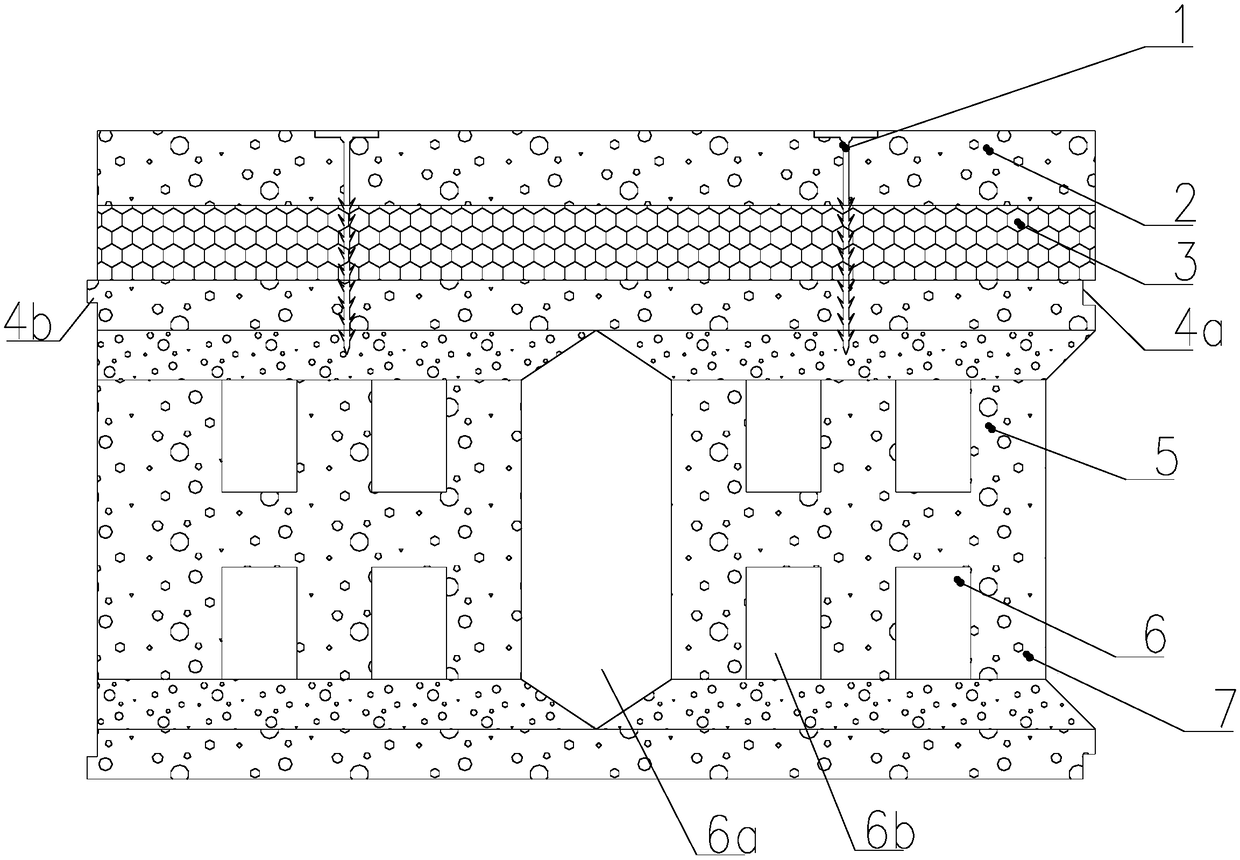

[0036] refer to figure 2 , 6 , the second embodiment of the present invention: a vertical hole grouting type composite self-insulating block, including block outer leaf 2, insulation layer 3, block inner leaf 5, block outer leaf 2 arranged sequentially from outside to inside , insulation layer 3, and block inner pages 5 are fixedly connected by anchor bolts 1, and an accommodation groove 7 is provided on the upper end surface of the block inner pages 5; one of the left and right sides of the block inner pages 5 is provided The groove and the other side are flushly arranged, and a vertical cavity 6 is arranged through the block inner page 5 along the up and down direction of the block inner page 5 . The vertical cavity 6 includes a plurality of cavities located on the inner page 5 of the block, and the plurality of cavities include a symmetrical cavity 6a located in the middle of the inner page 5 of the block and a cavity located on both sides of the symmetrical cavity 6a. T...

no. 3 example

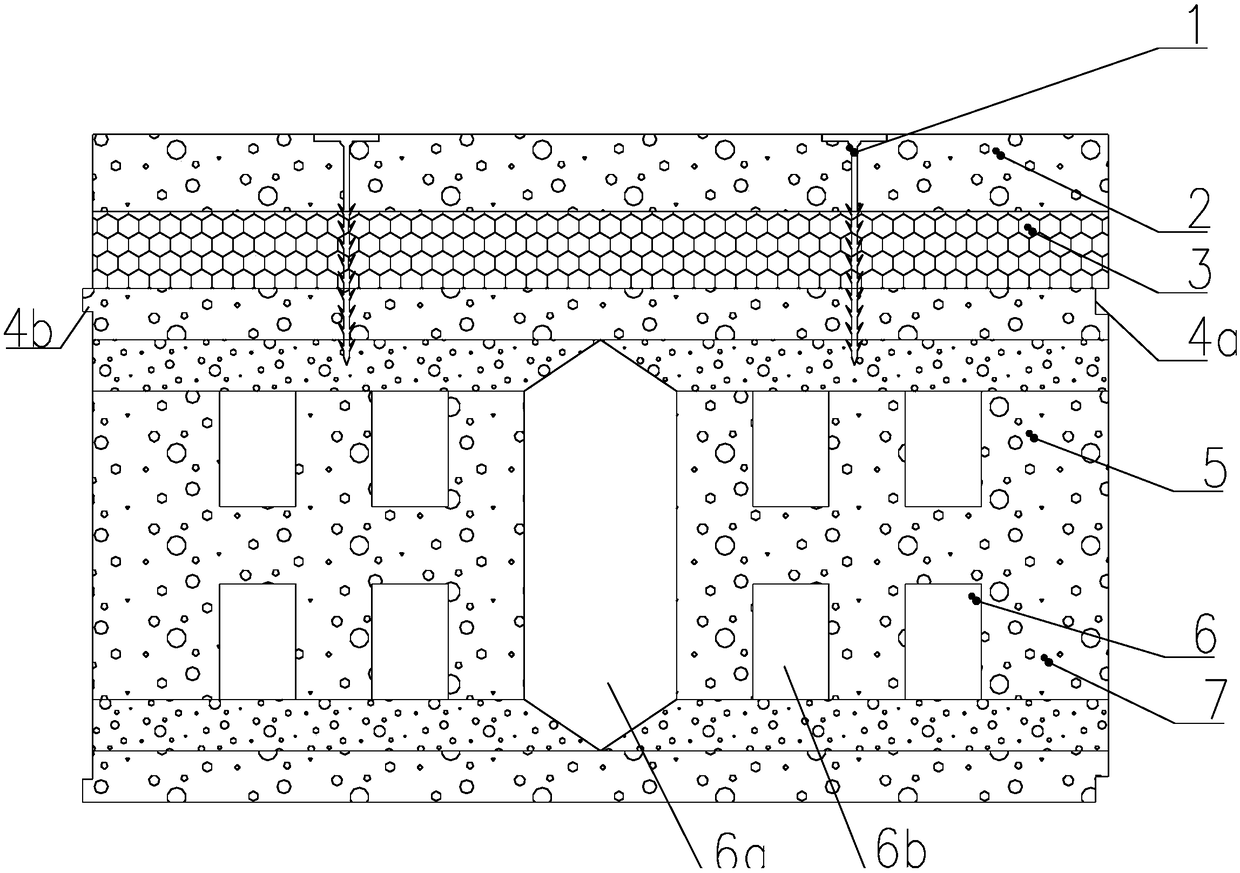

[0037] refer to image 3 , the third embodiment of the present invention: a vertical hole grouting type composite self-insulating block, including block outer pages 2, insulation layers 3, block inner pages 5, block outer pages 2 arranged sequentially from outside to inside , the insulation layer 3, and the block inner pages 5 are fixedly connected by anchor bolts 1, and the upper end surface of the block inner pages 5 is provided with an accommodation groove 7; the left and right sides of the block inner pages 5 are arranged evenly, A vertical cavity 6 is arranged through the block inner page 5 along the up and down direction of the block inner page 5 . The vertical cavity 6 includes a plurality of cavities located on the inner page 5 of the block, and the plurality of cavities include a symmetrical cavity 6a located in the middle of the inner page 5 of the block and a cavity located on both sides of the symmetrical cavity 6a. The set of auxiliary holes 6b symmetrically open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com