Assembly type automatic heat preservation integrated external wallboard

An external wall panel and self-insulation technology, which is applied in the direction of insulation, building components, buildings, etc., can solve the problems of rainwater leakage from the wall, the overall insulation of the wall, and the impact on the insulation effect of the building. Rainwater seepage, improve thermal insulation effect, reduce the effect of bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

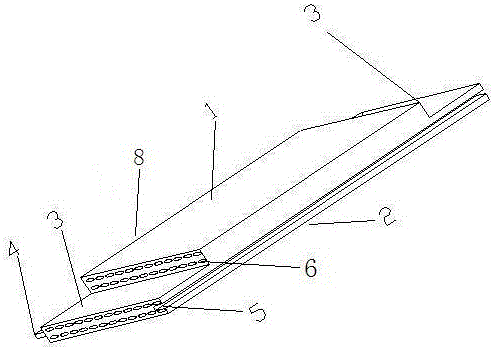

[0042] Such as figure 1 , 4 As shown, the present invention includes an exterior wall panel body 8. The exterior wall panel body 8 includes an outer panel 2 and an inner panel 1. The outer panel 2 and the inner panel 1 are of an integrated structure. The two ends of the inner panel 1 are along the length of the outer panel 2. The direction is indented inwardly, and the outer plate 2 at both ends of the inner plate 1 forms a beam contact portion A3, and the outer plate 2 and the inner plate 1 are provided with a plurality of through holes 6 along the length direction; the width dimension of the inner plate 1 is the same as that of the outer The boards 2 have the same width and size, and the length of the inner board 1 is smaller than the length of the outer board 2; the inner board 1 and the outer board 2 are provided with more than one row of through holes 6, and the through holes 6 in adjacent rows are arranged in a staggered manner , The through hole 6 is filled with an ins...

Embodiment 2

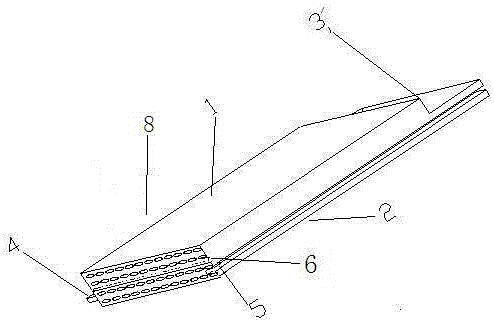

[0044] Such as figure 2 As shown in , the present invention includes an exterior wall panel body 8, and the exterior wall panel body 8 includes an outer panel 2 and an inner panel 1. The outer panel 2 and the inner panel 1 have an integrated structure, and one end of the inner panel 1 is along the The length direction is indented inward, and the part of the outer plate 2 at the end of the inner plate 1 forms a beam contact portion B3', and a plurality of through holes 6 are arranged inside the outer plate 2 and the inner plate 1 along the length direction; the width dimension of the inner plate 1 is Smaller than the width of the outer plate 2, the length of the inner plate 1 is smaller than the length of the outer plate 2; both the inner plate 1 and the outer plate 2 are provided with more than one row of through holes 6, and the through holes 6 in adjacent rows are arranged in a staggered manner , The through hole 6 is filled with an insulating material 61 .

Embodiment 3

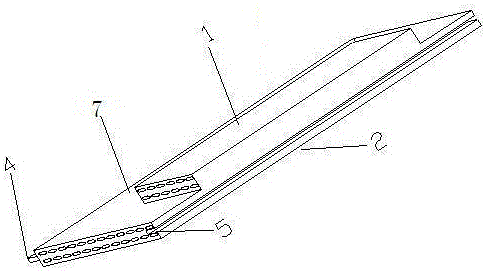

[0046] Such as image 3 , 4 As shown, the present invention includes an outer panel 2 and an inner panel 1. The outer panel 2 and the inner panel 1 are of an integrated structure. The width direction of the outer plate 2 is indented inwardly, the two ends of the inner plate 1 and the part of the outer plate 2 on the side adjacent to the two ends form the beam-column contact portion 7, and the inner sides of the outer plate 2 and the inner plate 1 are arranged along the length direction. A plurality of through holes 6; the width of the inner plate 1 is the same as that of the outer plate 2, and the length of the inner plate 1 is smaller than the length of the outer plate 2; the inner plate 1 and the outer plate 2 are provided with more than one row of through holes 6, The through-holes 6 of adjacent rows are arranged in a staggered manner, and the through-holes 6 are filled with insulating materials 61

[0047] combine figure 1 , 2 , 3, 4 Briefly describe the use process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com