A kind of preparation method of geological drill bit

A drill bit and geology technology, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of high cost, inconvenient preparation and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

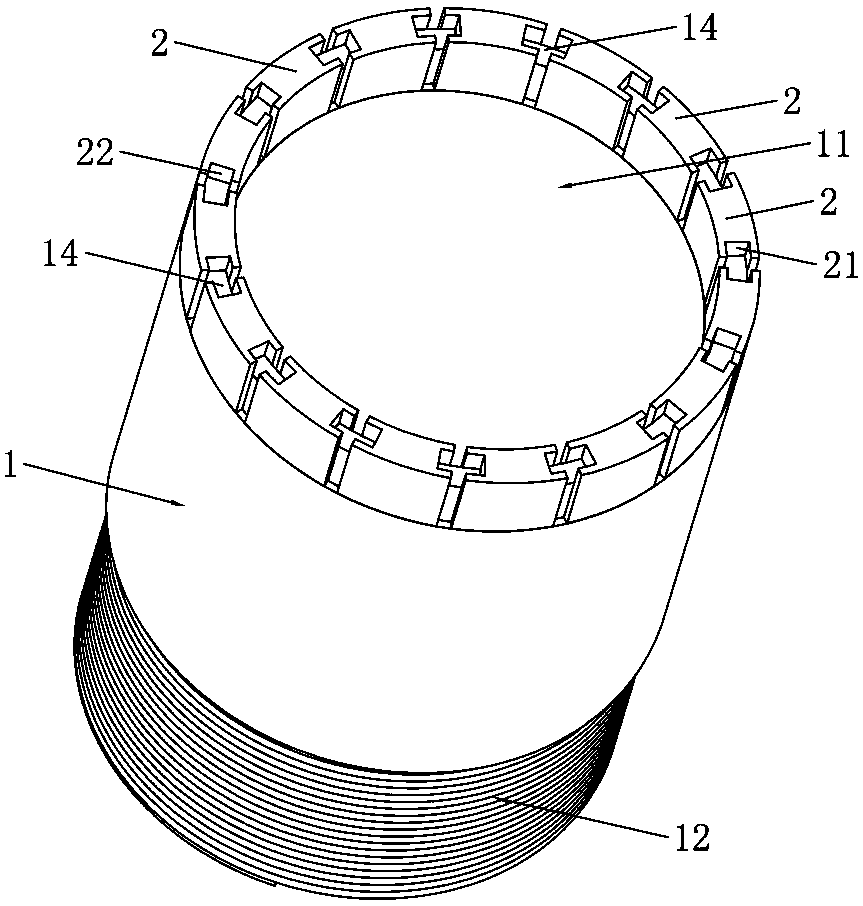

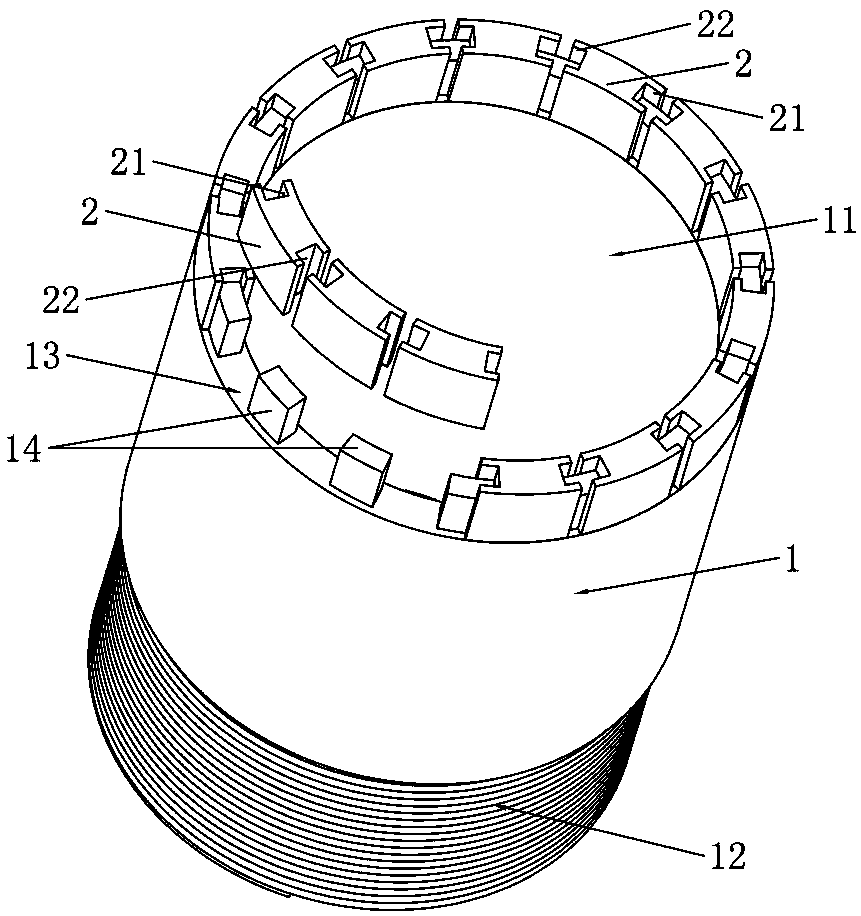

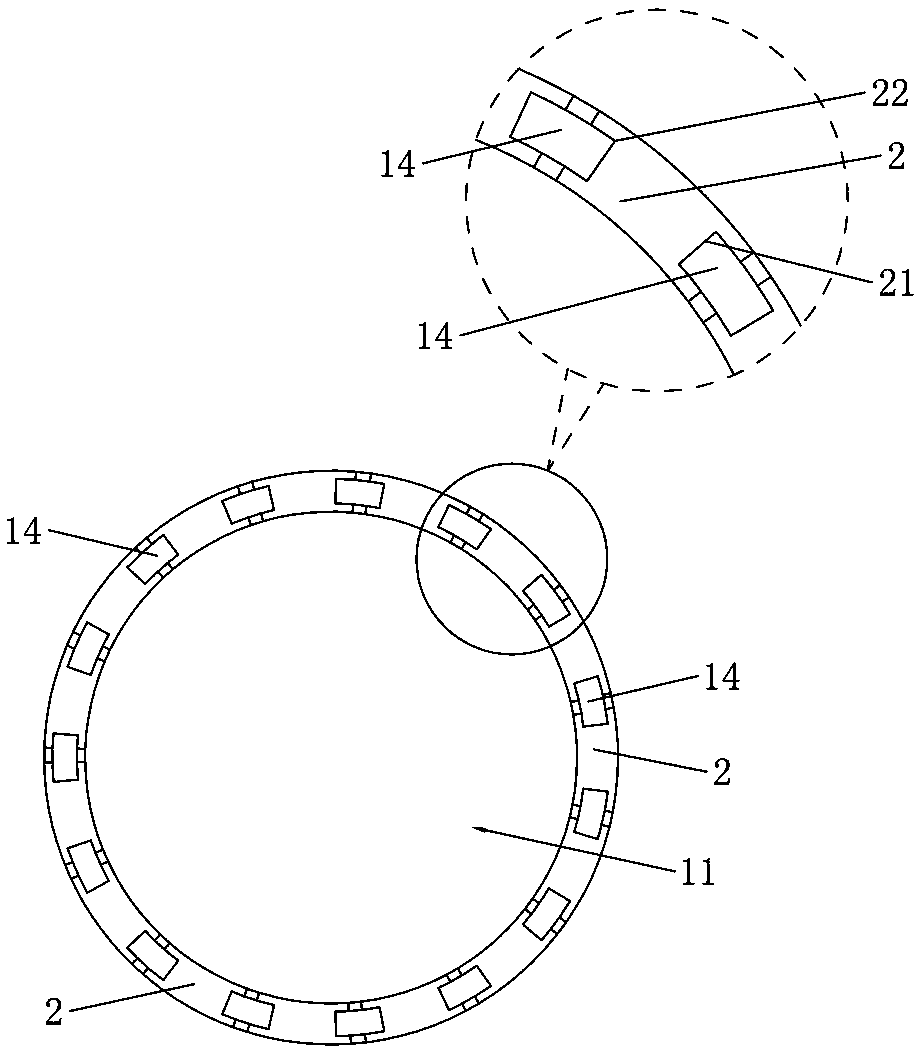

[0050] Embodiment one, a kind of preparation method of geological drill bit, comprises following process steps, specifically:

[0051] a. Prepare the metal pipe body 1: select and cut the metal pipe body 1 according to the design size, the design size includes the diameter value of the central hole 11 of the pipe body, the outer diameter value of the metal pipe body 1, and the height value of the metal pipe body 1, The metal pipe body 1 is a steel pipe body or an iron pipe body, and then the cut metal pipe body 1 is placed on a lathe and the external thread connection part 12 is turned on the outer circumference of the lower end of the metal pipe body 1; 12 After the turning is completed, the metal pipe body 1 is placed on the CNC lathe and the cutter head installation groove 13 is processed on the upper edge of the metal pipe body 1 by the CNC lathe. The number of cutter head installation grooves 13 on the upper edge of the metal pipe body 1 According to the design setting and ...

Embodiment 2

[0067] Embodiment 2, a preparation method of a geological drill bit, including the following process steps, specifically:

[0068] a. Prepare the metal pipe body 1: select and cut the metal pipe body 1 according to the design size, the design size includes the diameter value of the central hole 11 of the pipe body, the outer diameter value of the metal pipe body 1, and the height value of the metal pipe body 1, The metal pipe body 1 is a steel pipe body or an iron pipe body, and then the cut metal pipe body 1 is placed on a lathe and the external thread connection part 12 is turned on the outer circumference of the lower end of the metal pipe body 1; 12 After the turning is completed, the metal pipe body 1 is placed on the CNC lathe and the cutter head installation groove 13 is processed on the upper edge of the metal pipe body 1 by the CNC lathe. The number of cutter head installation grooves 13 on the upper edge of the metal pipe body 1 According to the design setting and al...

Embodiment 3

[0084] Embodiment three, a kind of preparation method of geological drill bit, comprises following process step, specifically:

[0085] a. Prepare the metal pipe body 1: select and cut the metal pipe body 1 according to the design size, the design size includes the diameter value of the central hole 11 of the pipe body, the outer diameter value of the metal pipe body 1, and the height value of the metal pipe body 1, The metal pipe body 1 is a steel pipe body or an iron pipe body, and then the cut metal pipe body 1 is placed on a lathe and the external thread connection part 12 is turned on the outer circumference of the lower end of the metal pipe body 1; 12 After the turning is completed, the metal pipe body 1 is placed on the CNC lathe and the cutter head installation groove 13 is processed on the upper edge of the metal pipe body 1 by the CNC lathe. The number of cutter head installation grooves 13 on the upper edge of the metal pipe body 1 According to the design setting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com