Manufacturing method of conical mica tube

A production method and technology of mica tubes, which are applied to electrical components, insulators, circuits, etc., can solve the problems of high mica tube strength and inability to make conical mica tubes, and achieve low production costs, reliable and effective production technical parameters, and a preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment carries out the making of tapered mica pipe, comprises the following steps:

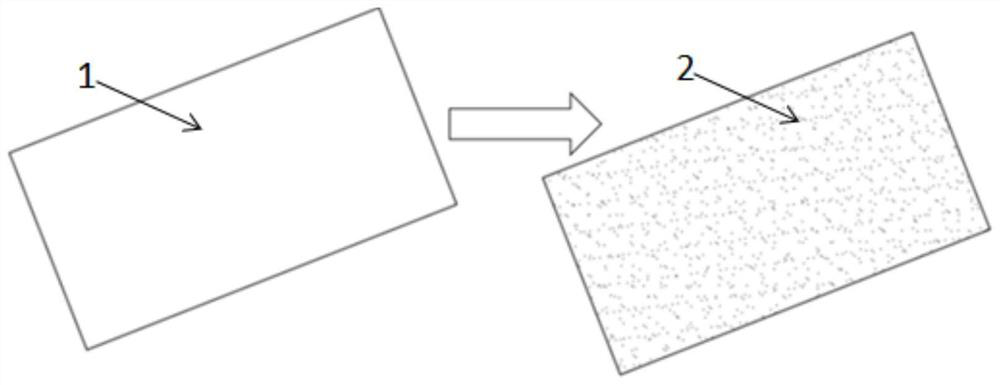

[0035] (1) Brush organic silica gel evenly on the surface of mica paper 1 with a glue brushing device, dry and gel for 120 seconds, and obtain mica glued paper 2 with a mass content of organic silica gel of 7.2%;

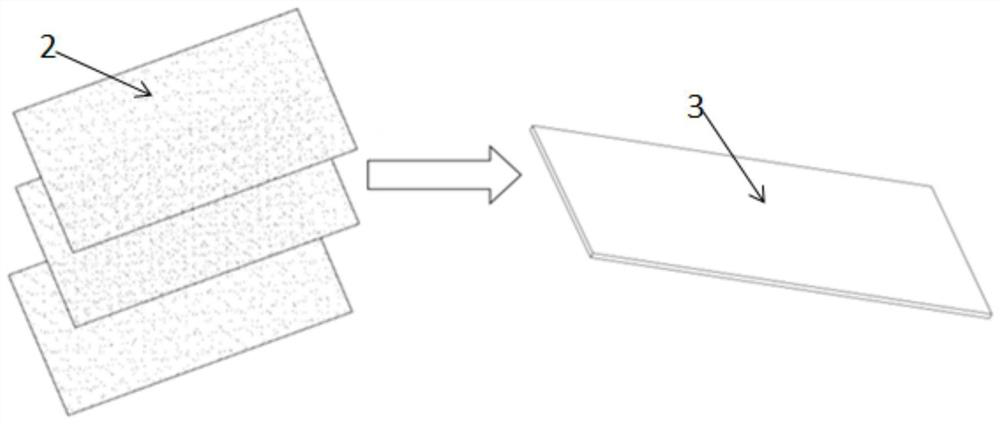

[0036] (2) Put 9 pieces of mica glued paper 2 into a molding machine, pressurize the mica glued paper 2 into a mica board 3 with a pressing pressure of 50 MPa, a pressurizing time of 5 minutes, and a heating temperature of 50° C.;

[0037] (3) the mica plate 3 is processed into the required fan-shaped mica plate 4 by machining technology;

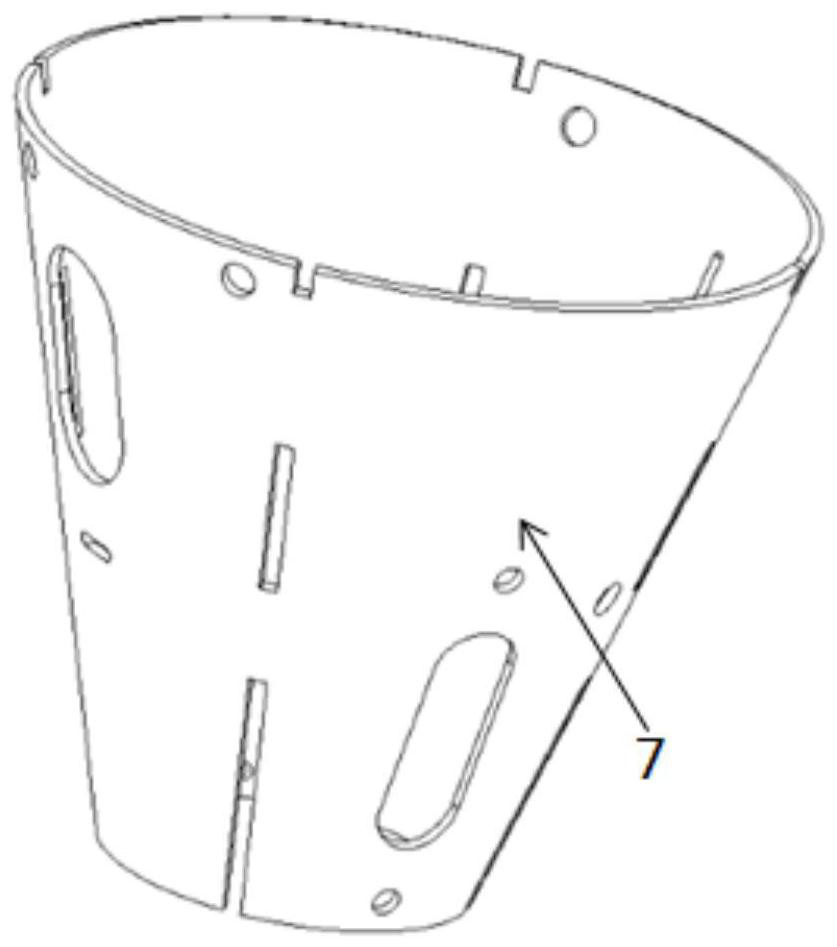

[0038] (4) The fan-shaped mica plate 4 is slowly bent and bonded to the surface of the male mold 6, and then the fan-shaped mica plate 4 is put into the female mold 5 to surround and fit to form a truncated conical shape, and the male mold 6 is closed for shaping. The setting time is 200 seconds, and it becomes a tapered t...

Embodiment 2

[0042] The present embodiment carries out the making of tapered mica pipe, comprises the following steps:

[0043] (1) Evenly brush the organic silica gel on the surface of the mica paper 1 with a glue brushing device, dry and gel for 240 seconds, and obtain the mica glued paper 2 with a mass content of organic silica gel of 6%;

[0044] (2) Put 12 pieces of mica glued paper 2 into a molding machine, pressurize the mica glued paper 2 into a mica board 3 with a pressing pressure of 10 MPa, a pressurizing time of 20 minutes, and a heating temperature of 20° C.;

[0045] (3) the mica plate 3 is processed into the required fan-shaped mica plate 4 by machining technology;

[0046] (4) The fan-shaped mica plate 4 is slowly bent and bonded to the surface of the male mold 6, and then the fan-shaped mica plate 4 is put into the female mold 5 to surround and fit to form a truncated conical shape, and the male mold 6 is closed for shaping. The setting time is 300 seconds, and it becomes...

Embodiment 3

[0050] The present embodiment carries out the making of tapered mica pipe, comprises the following steps:

[0051] (1) Brush organic silica gel evenly on the surface of the mica paper 1 with a glue brushing device, dry and gel for 20 seconds, and obtain mica glued paper 2 with a mass content of organic silica gel of 15%;

[0052] (2) Put 5 pieces of mica glued paper 2 into a molding machine, pressurize the mica glued paper 2 into a mica plate 3 with a pressure of 200 MPa, a pressurization time of 1 minute, and a heating temperature of 80° C.;

[0053] (3) the mica plate 3 is processed into the required fan-shaped mica plate 4 by machining technology;

[0054] (4) The fan-shaped mica plate 4 is slowly bent and bonded to the surface of the male mold 6, and then the fan-shaped mica plate 4 is put into the female mold 5 to surround and fit to form a truncated conical shape, and the male mold 6 is closed for shaping. The setting time is 10 seconds, and it becomes a tapered tube pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com