A kind of preparation method of cemented carbide round bar

A cemented carbide and round rod technology, applied in the field of cemented carbide, can solve the problems of low qualification rate and difficult quality assurance of cemented carbide round rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

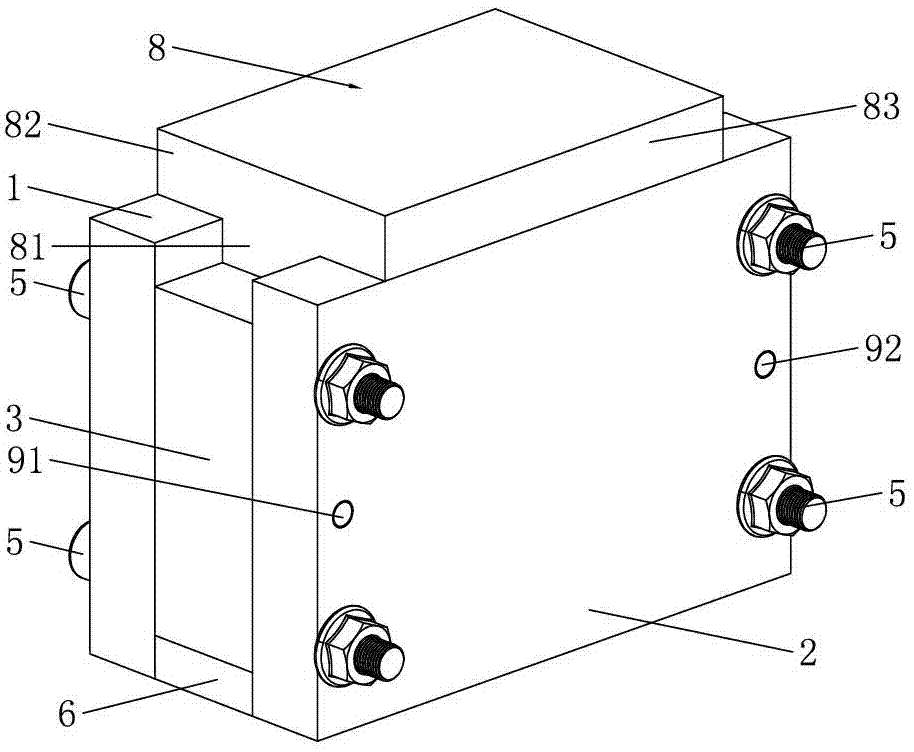

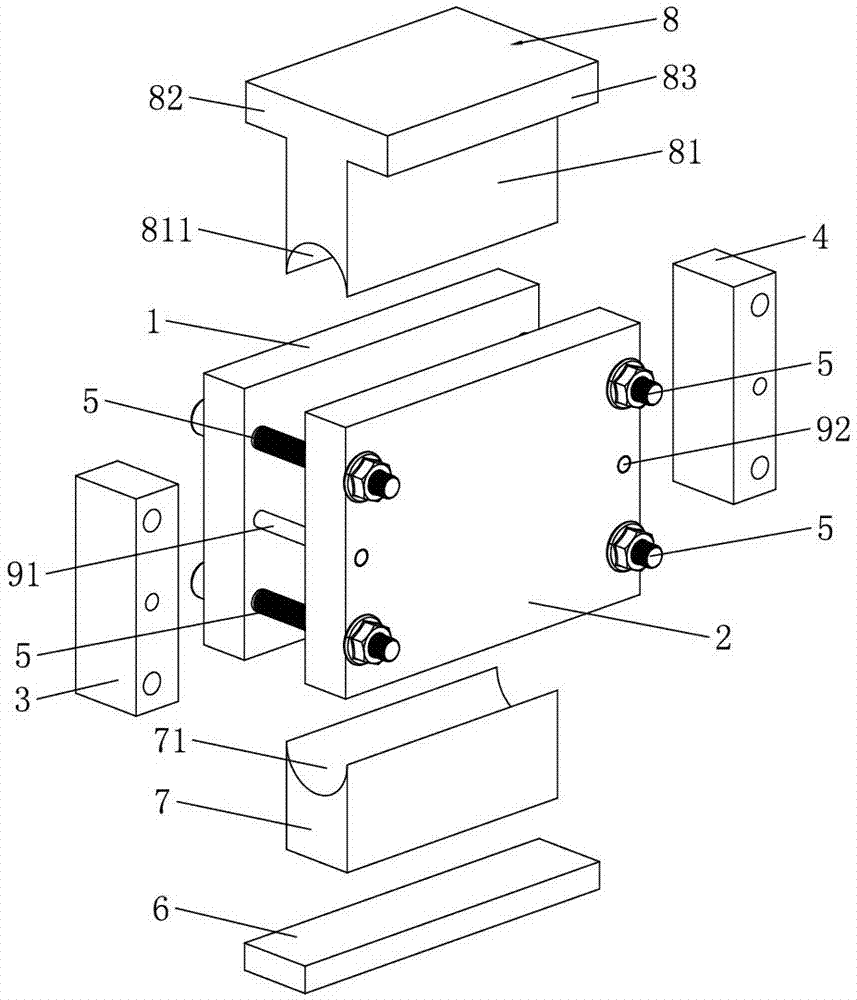

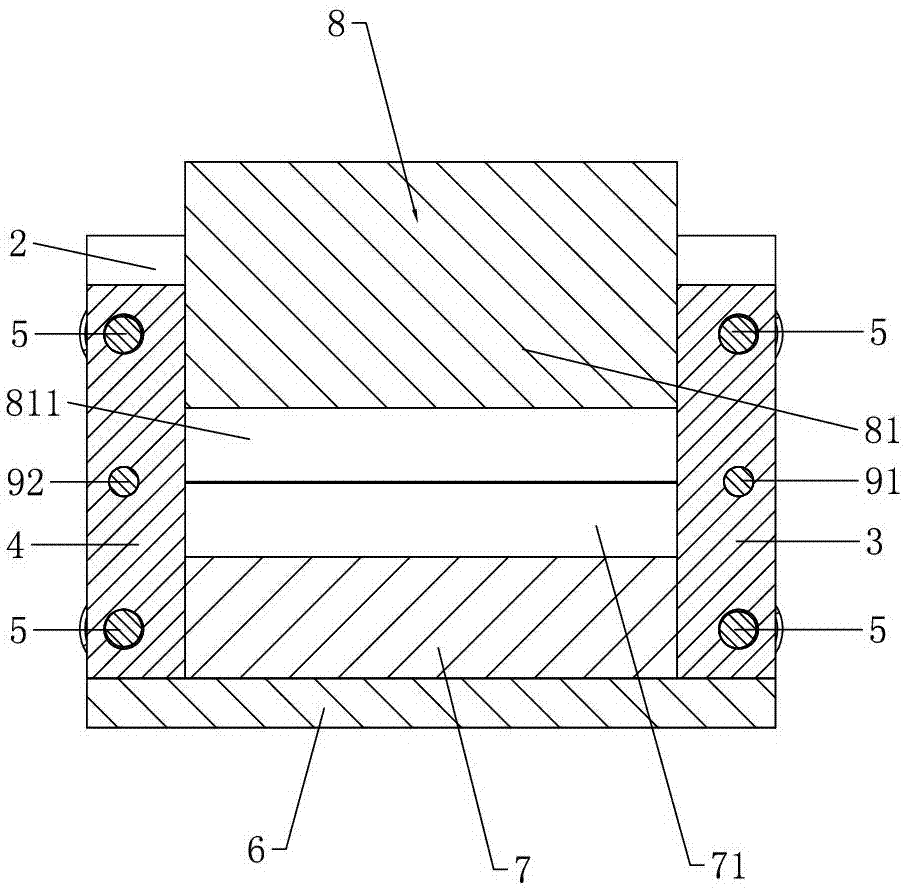

Image

Examples

Embodiment Construction

[0035] The present invention will be described below in conjunction with specific embodiments.

[0036] A method for preparing a cemented carbide round bar, comprising the following process steps, specifically:

[0037] a. Preparation of cemented carbide powder: put WC powder, cobalt powder and chromium carbide powder in a ball mill and mix for 10 hours to obtain cemented carbide powder. There are three types of cemented carbide powder: WC powder, cobalt powder and chromium carbide powder The parts by weight of the material are 89.7%, 10%, 0.3% successively;

[0038] B, preparation molding agent: first dissolve 1.5 kilograms of buna rubber and 0.5 kilogram of paraffin in 30 liters of gasoline and rapeseed oil mixed solution, the volume parts of gasoline and rapeseed oil in the gasoline and rapeseed oil mixed solution are successively 75%, 25%, then the mixed solution of gasoline and rapeseed oil dissolved in Buna rubber and paraffin was placed in a viscous mixer and stirred f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com