Pressure formation plate and preparation method therefor

A technology of pressure and copper plate, which is applied in the field of pressure forming plate and its preparation, can solve the problems of low flatness, poor contact, and limitation of power soft package lithium battery formation capacity ratio, etc., and achieve high surface roughness and electrical conductivity. The effect of increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described below in conjunction with specific embodiments.

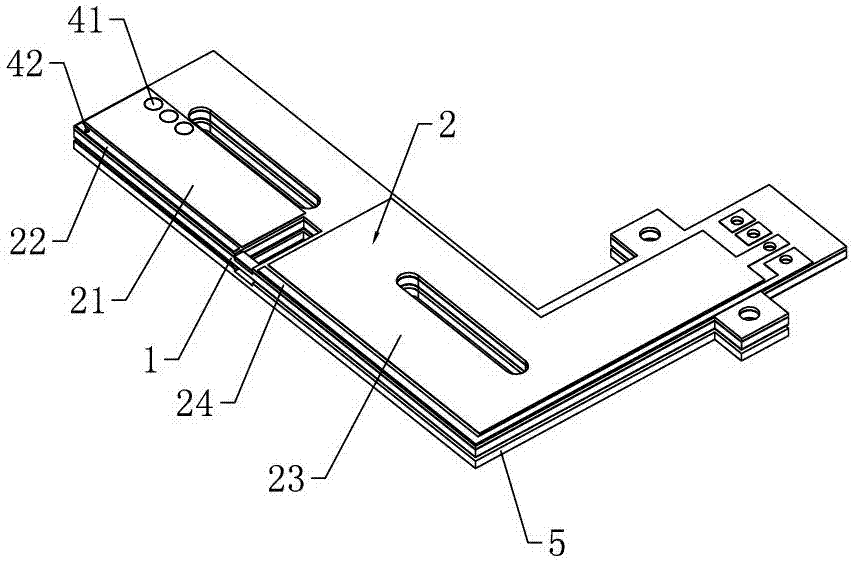

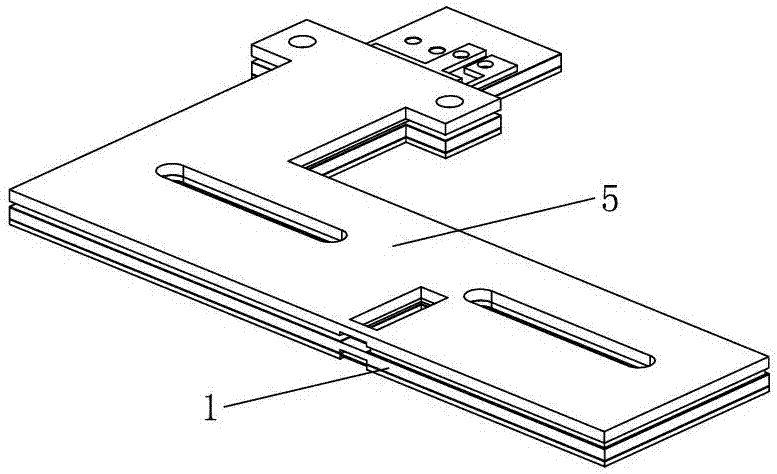

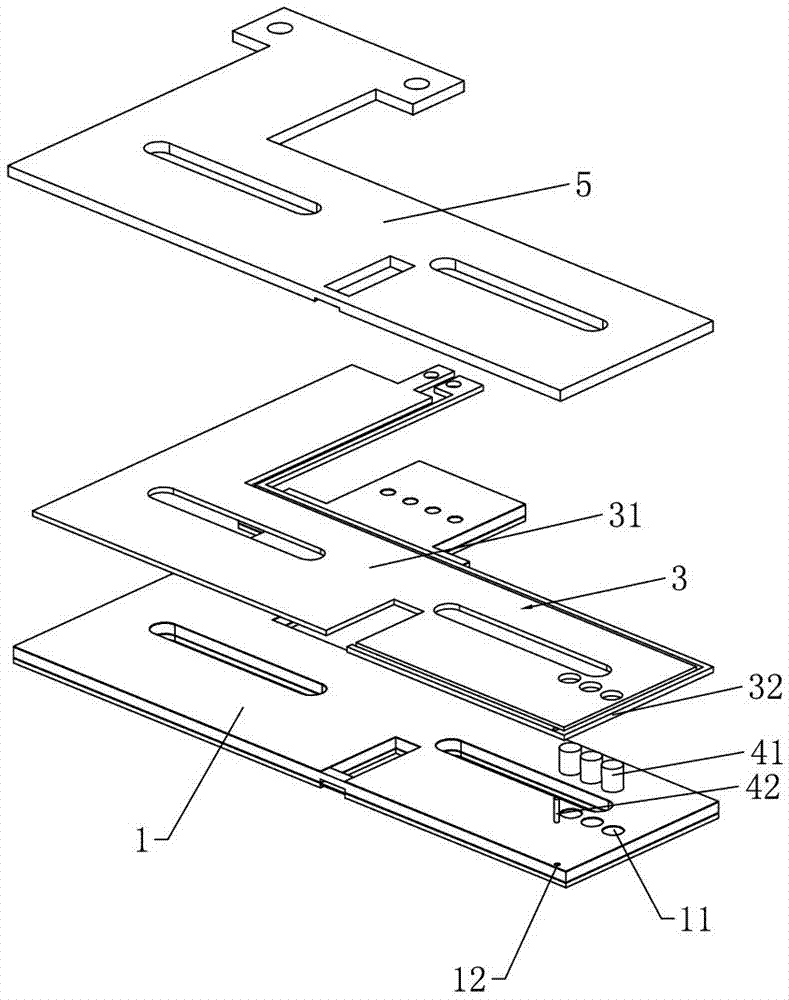

[0042] A pressure forming board, comprising a substrate 1, an upper copper plate 2 is laminated on the upper surface of the substrate 1, a lower copper plate 3 is laminated on the lower surface of the substrate 1, and the thickness values of the upper copper plate 2 and the lower copper plate 3 are respectively Greater than 0.2mm.

[0043]Further, the upper copper plate 2 is engraved with the positive current sheet 21, the positive voltage sheet 22, the negative current sheet 23, the negative voltage sheet 24, the positive current sheet 21, the positive voltage sheet 22, and the negative current sheet which are sequentially arranged at intervals through a fine engraving machine. 23. The upper surface of the negative electrode current sheet 23 is a rough surface after being wire-drawn by a wire drawing machine, and the lower copper plate 3 is engraved with a lower side current con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com