Plate rolling machine with cooling function

A plate rolling machine and functional technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of fast speed of plate rolling machine, high pressure adjustment of plate rolling machine, poor heat dissipation conditions, etc., to reduce the risk of burnout chance, saving power, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

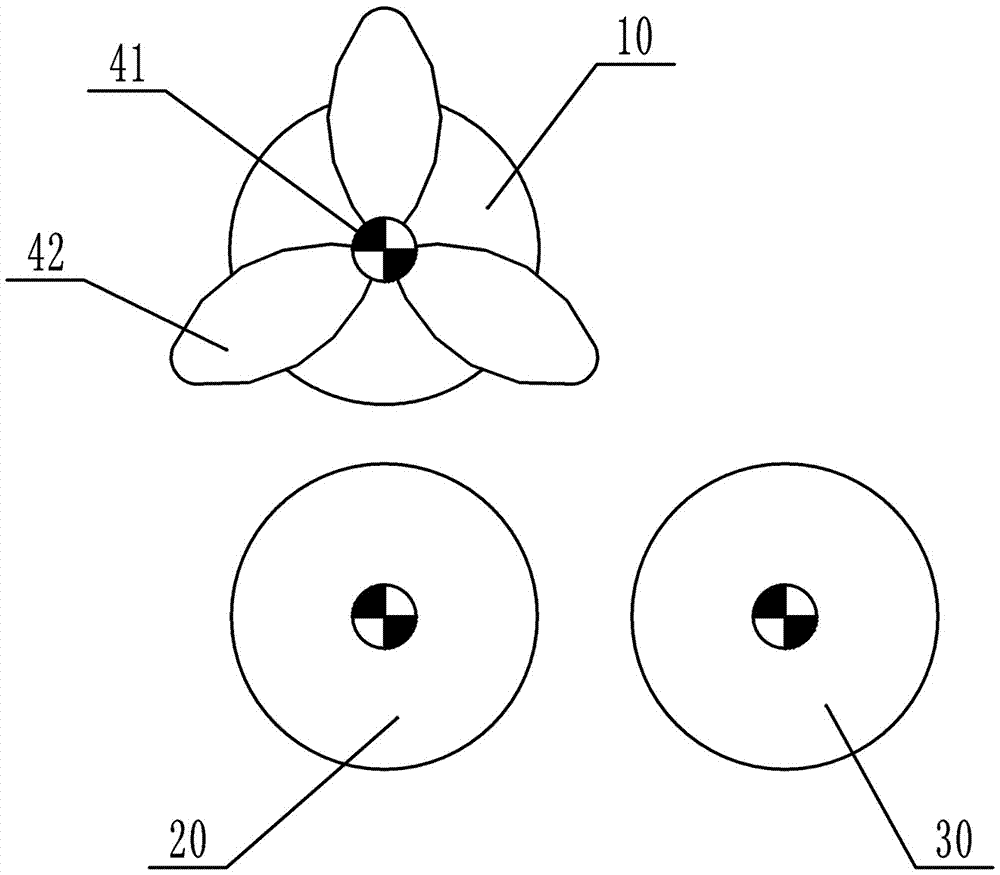

[0017] Such as figure 1 As shown, the plate bending machine with cooling function includes a frame, an upper roller 10, a lower roller 20, an edge roller 30 and a power source for driving the upper roller 10 to rotate. The power source is a servo motor, which is more controllable and has a longer service life than ordinary motors. The upper roller 10, the lower roller 20 and the side roller 30 are all rotatably connected to the frame. In addition, it also includes a first connecting shaft 41 and a first fan blade, the first connecting shaft 41 is coaxially connected with the upper roller 10, and the first fan blade is installed on the first connecting shaft 41. The first fan blade is a plastic fan blade, the cost of the plastic fan blade is low, and the gravity is light, and it is easier to drive the plastic fan blade to rotate.

[0018] During specific work, the steel plate is first placed between the upper roll 10 and the lower roll 20, and the servo motor is started, and the ...

Embodiment 2

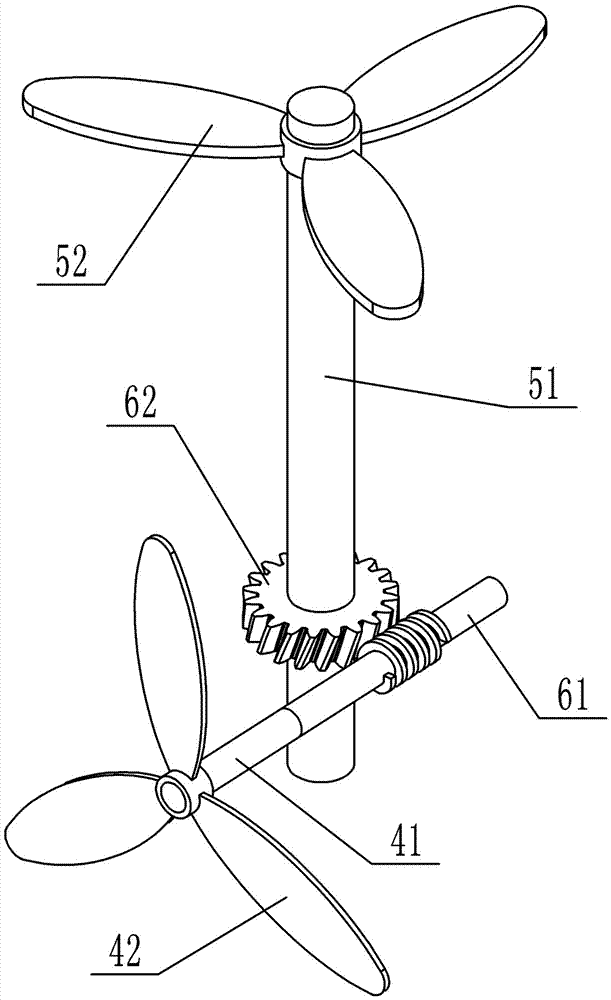

[0021] The difference between this solution and Embodiment 1 is that this solution also includes a worm gear 62, a worm 61 meshing with the worm gear 62, a second connecting shaft 51 and a second fan blade, and the worm 61 is coaxial with the first connecting shaft 41 connection. The worm gear 62 is installed on the second connecting shaft 51, and the second fan blade is installed on the second connecting shaft 51. When the upper roller 10 rotates, the worm 61 is driven to rotate, and the worm 61 drives the worm gear 62 to rotate, thereby prompting the second fan 52 on the second connecting shaft 51 to rotate, and cooling the side of the plate bending machine by blowing air, and the cooling effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com