A scalable packaging and weighing system for silane cross-linked cable material production line

A silane cross-linking and cable material technology, applied in packaging, transportation and packaging, packaging types and other directions, can solve the problems of high labor intensity, measurement error, waste in the discharging process, etc., saving manpower and time, and improving operation. Efficiency, the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

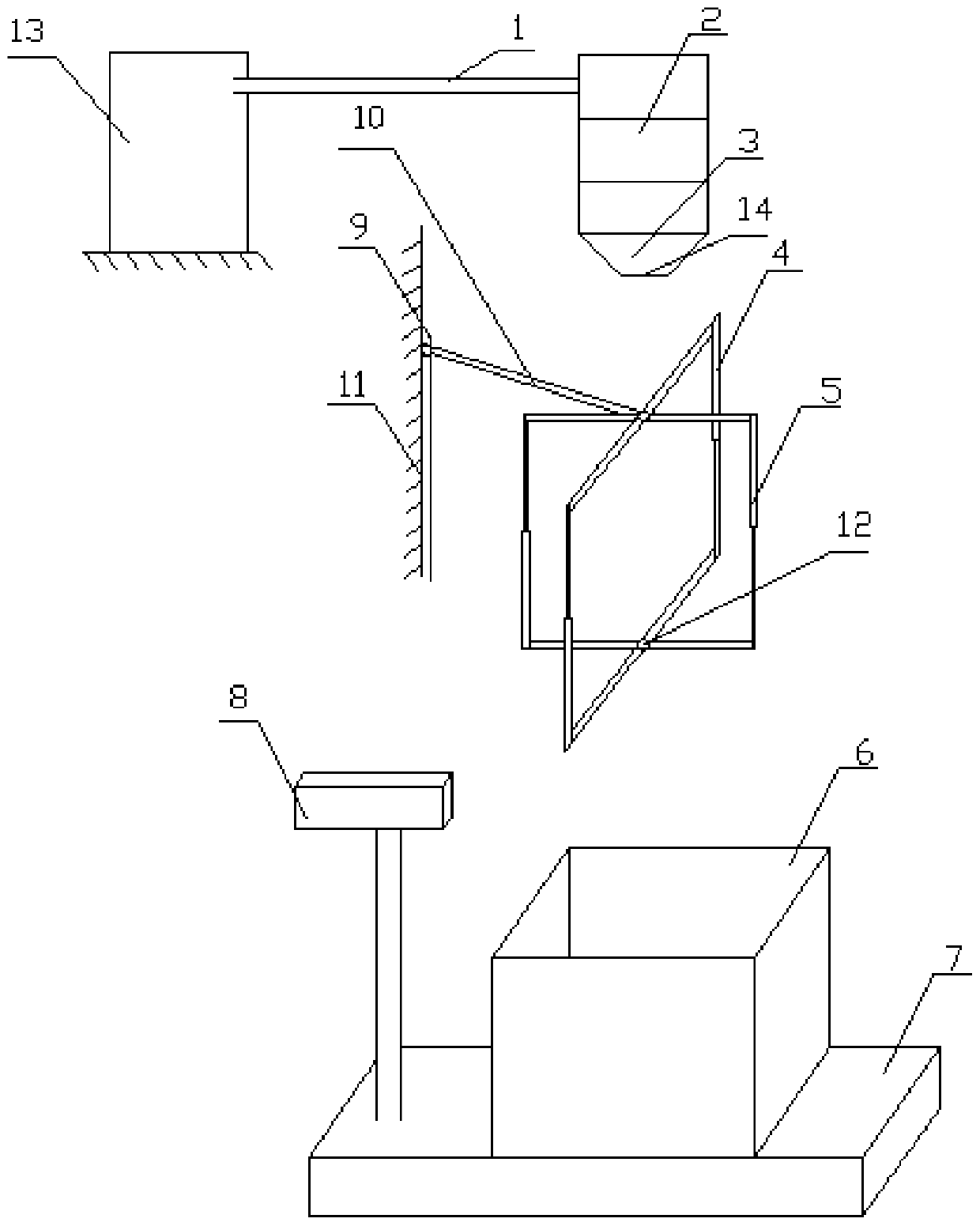

[0016] Such as figure 1 As shown, the present invention provides a scalable packaging and weighing system for a silane crosslinked cable material production line, including a silo, a telescopic rotating bracket for supporting the packaging bag, and a metering device. The central point of the hopper, the bracket, and the metering device are all on the same straight line perpendicular to the horizontal plane, the support is composed of a frame 4 and a frame 5, and the two frames 4 and 5 pass through the first and second connecting pieces 9 and 12 arranged at the center points of the upper and lower frames connected, the two frames 4 and 5 can rotate clockwise or counterclockwise, the angle between the first and second frames 4 and 5 is 0-360 degrees, the first frame 4 or the second frame 5 can Pull up and down to adjust the length of the frame as requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com