Core ball connecting device for restraining shaking of core ball during bending of pipe fitting

A connecting device and core ball technology, which is applied in the field of pipe bending and forming, can solve the problems of pipe fitting wall thickness and core ball vibration that affect the quality of the curved section, and achieve the effect of convenient installation and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

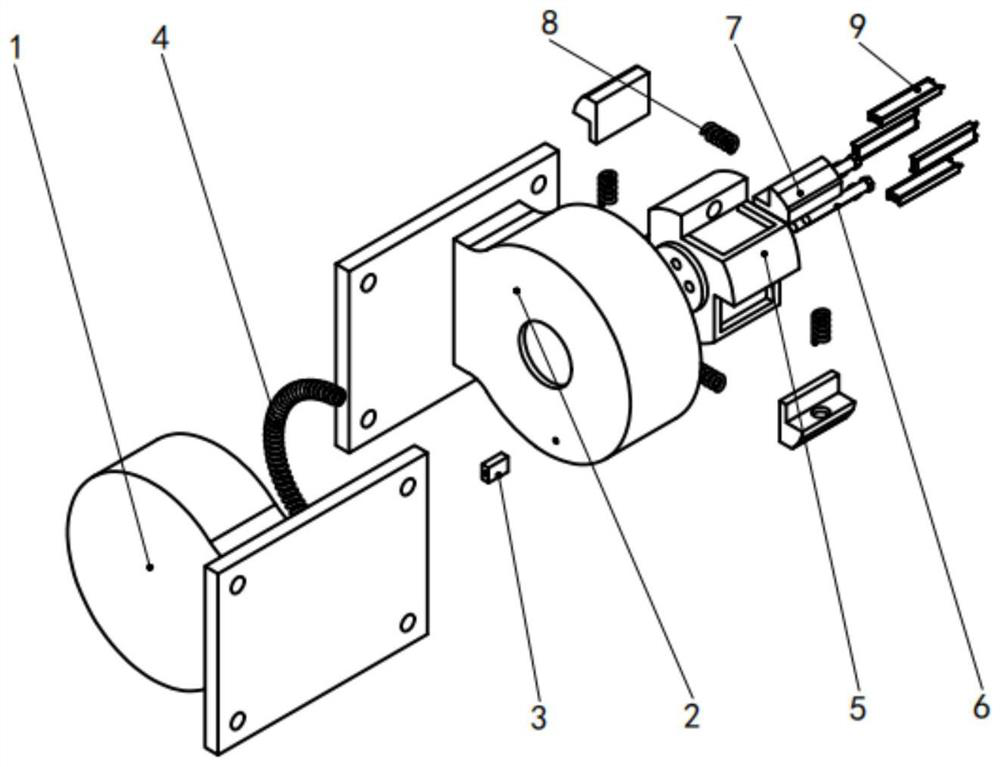

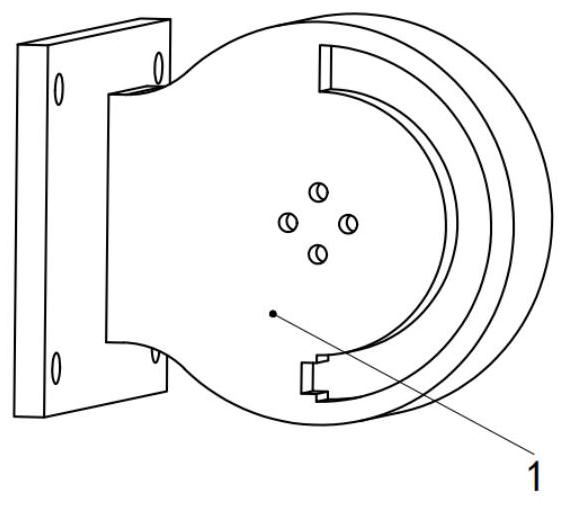

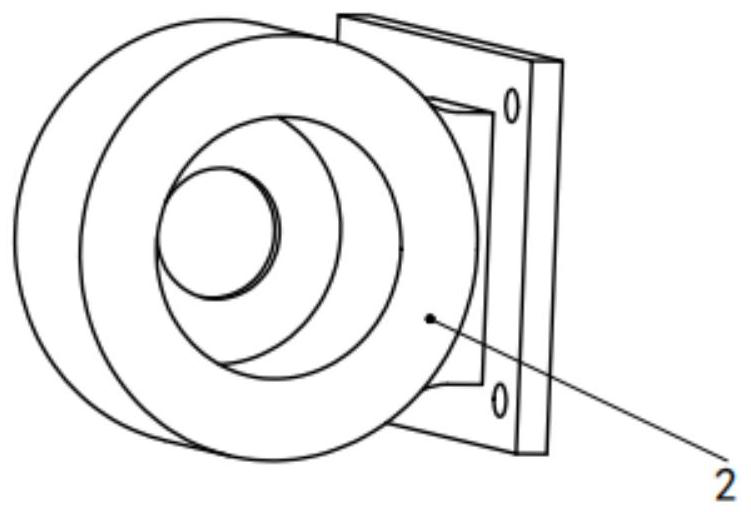

[0043] (1) Before the pipe is bent, the electromagnet 9 of the mandrel connecting device 10 is powered off, and the return spring 4 keeps the second connecting body 2 at the initial position, that is, all the core balls 12 and the mandrel 11 are in a straight line, and the wedge block 7 is in the Under the action of the pressure spring 8, it is in contact with the inner wall of the circular groove of the second connecting body 2, and the mandrel is placed in the pipe.

[0044] (2) During the bending process of pipe fittings, such as Figure 8 As shown, the electromagnet 9 remains powered off, and the deformation of the tube wall generates pressure on the core ball 12, and then the force is transmitted to the mandrel connecting device 10, and the wedge block 7 generates pressure on the inner wall of the circular groove of the second connecting body 2 under the action of the pressure spring 8. Due to the extrusion effect, the second connecting body 2 can only rotate clockwise re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com