Terminal assembling device and method for temperature sensor production

A temperature sensor and assembly device technology, applied in the assembly/disassembly of contacts, can solve the problems of difficulty in clamping, the flat structure of the terminal is small, and the depth of the terminal is difficult to control, so as to reduce the impact and improve the Conveying accuracy and conveying efficiency, the effect of easy alignment of plastic bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

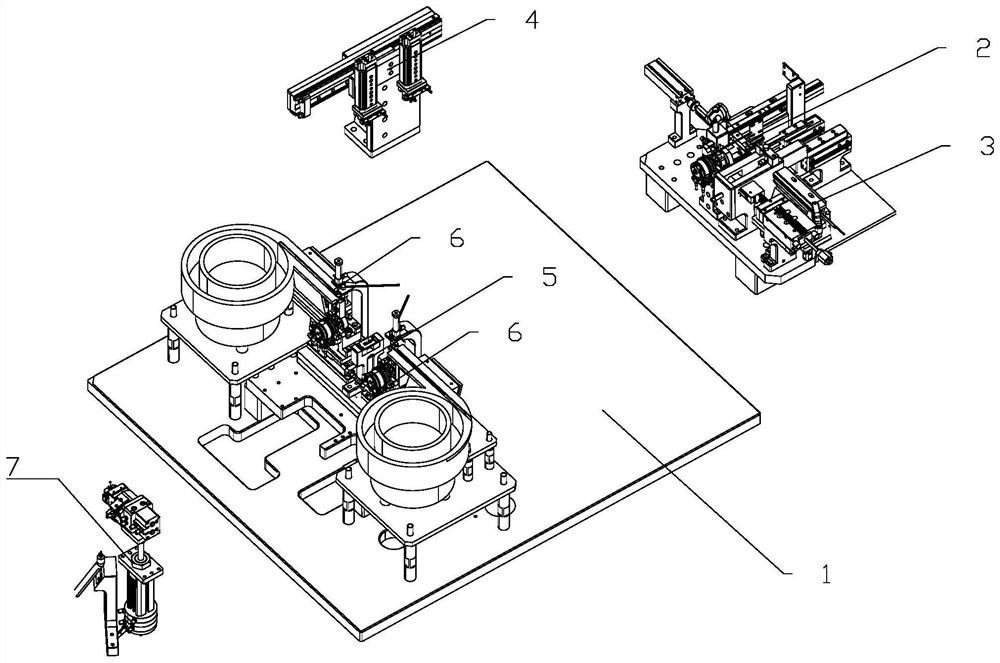

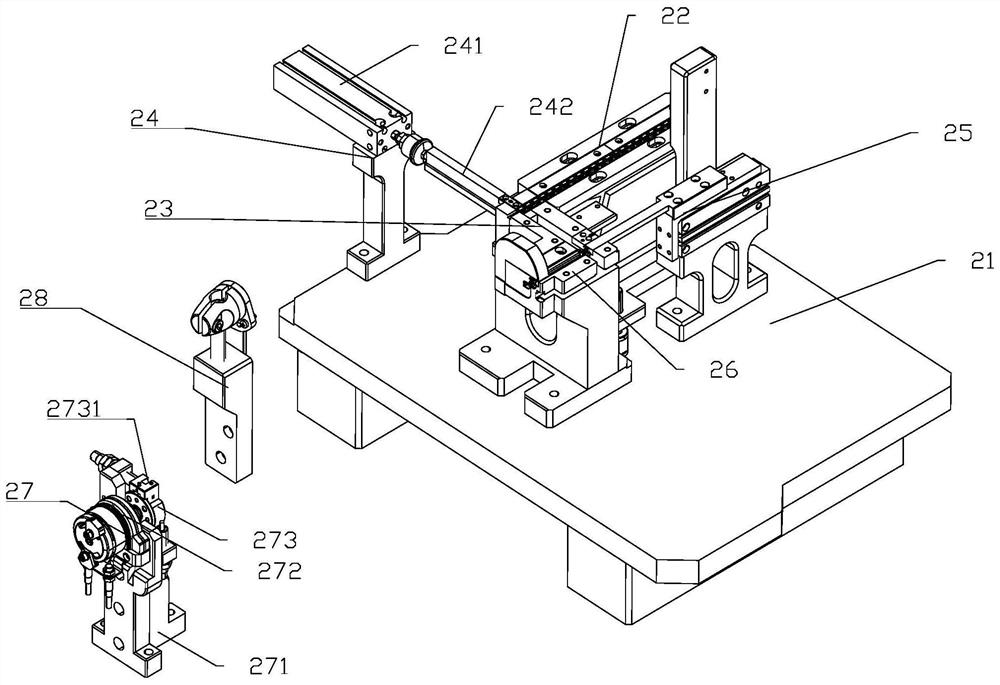

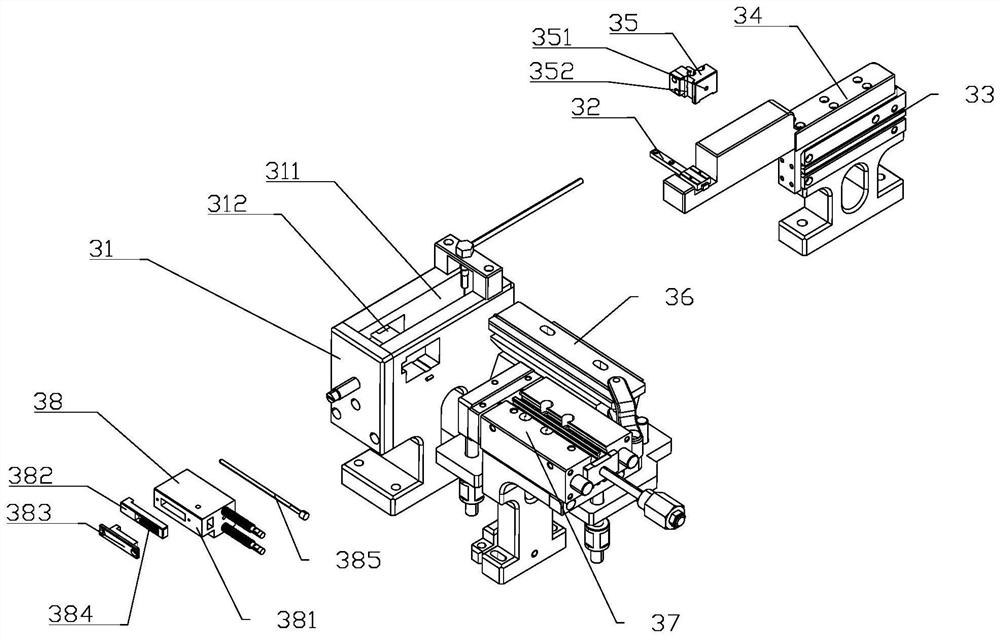

[0021] Such as figure 1 As shown, a temperature sensor production equipment includes a frame 1 and a plastic body feeding device 2, an induction rod assembly device 3, a handling device 4, a workbench 5, a terminal assembly device 6 and a discharging device installed on the frame 1. 7; The plastic body feeding device 2 and the induction rod assembly device 3 are arranged side by side, and the carrying device 4 connects the plastic body feeding device 2 and the workbench 5, the workbench 5 and the unloading device 7; Two sets of terminal assembly devices 6 are provided, and the terminal assembly devices 6 are arranged on both sides of the workbench 5, and the blanking device 7 is located behind the workbench 5.

[0022] The plastic body feeding device 2 is used to realize the feeding and circulation of the plastic body, the sensor rod assembly device 3 is used to assemble the sensor rod into the plastic body, and the workbench 5 is used to place the plastic body. The terminal asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com