A detachable lower ball seat for high-speed bridge swivel steel bearing

A technology of swivel steel and lower tee, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as hidden dangers of bridge safety, position deviation, and difficulty in bridge operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

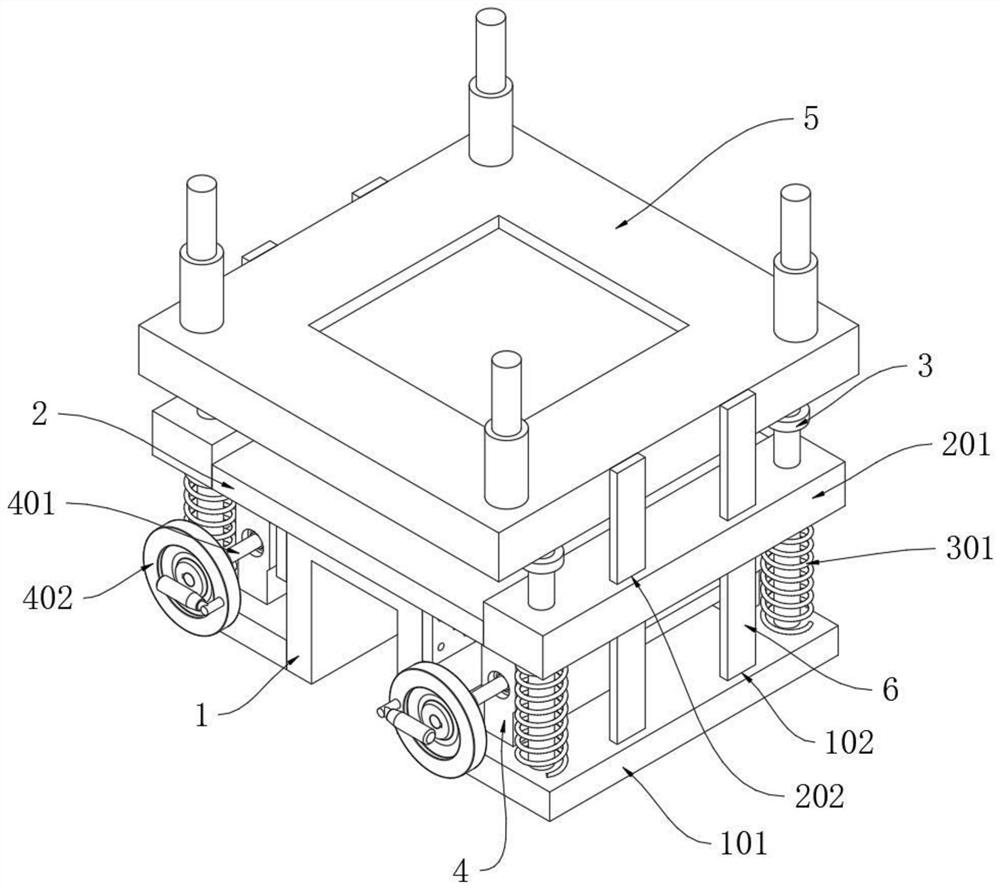

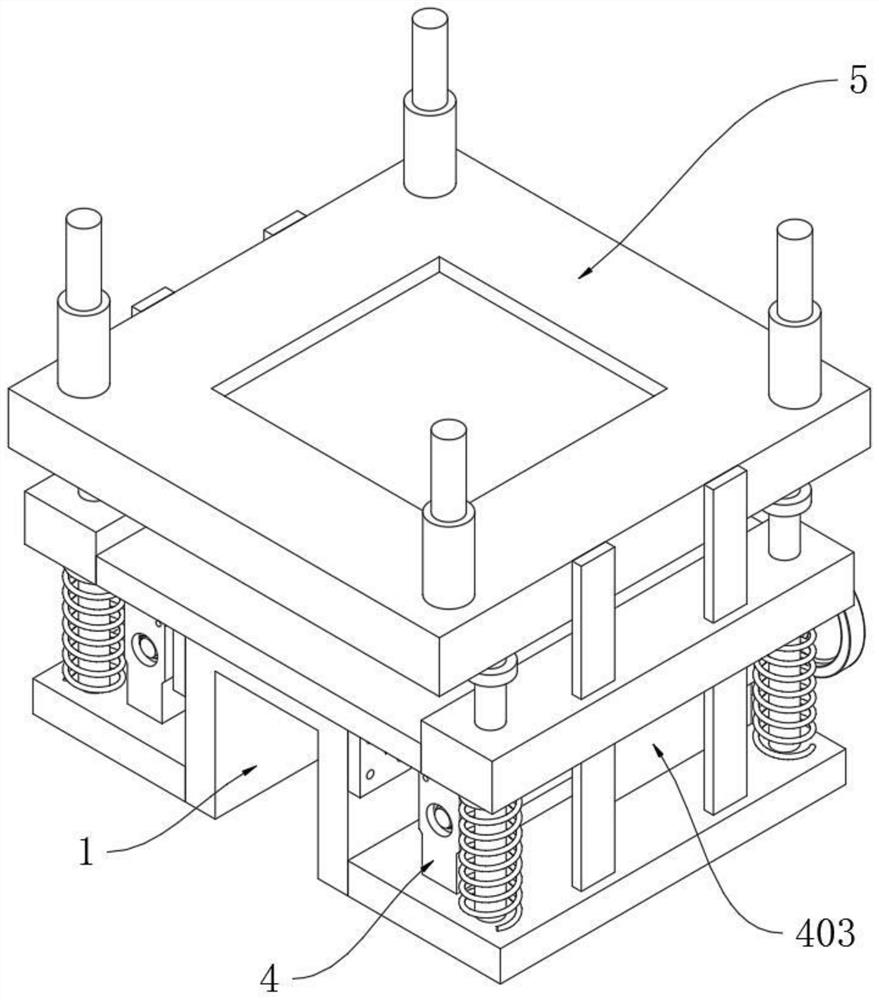

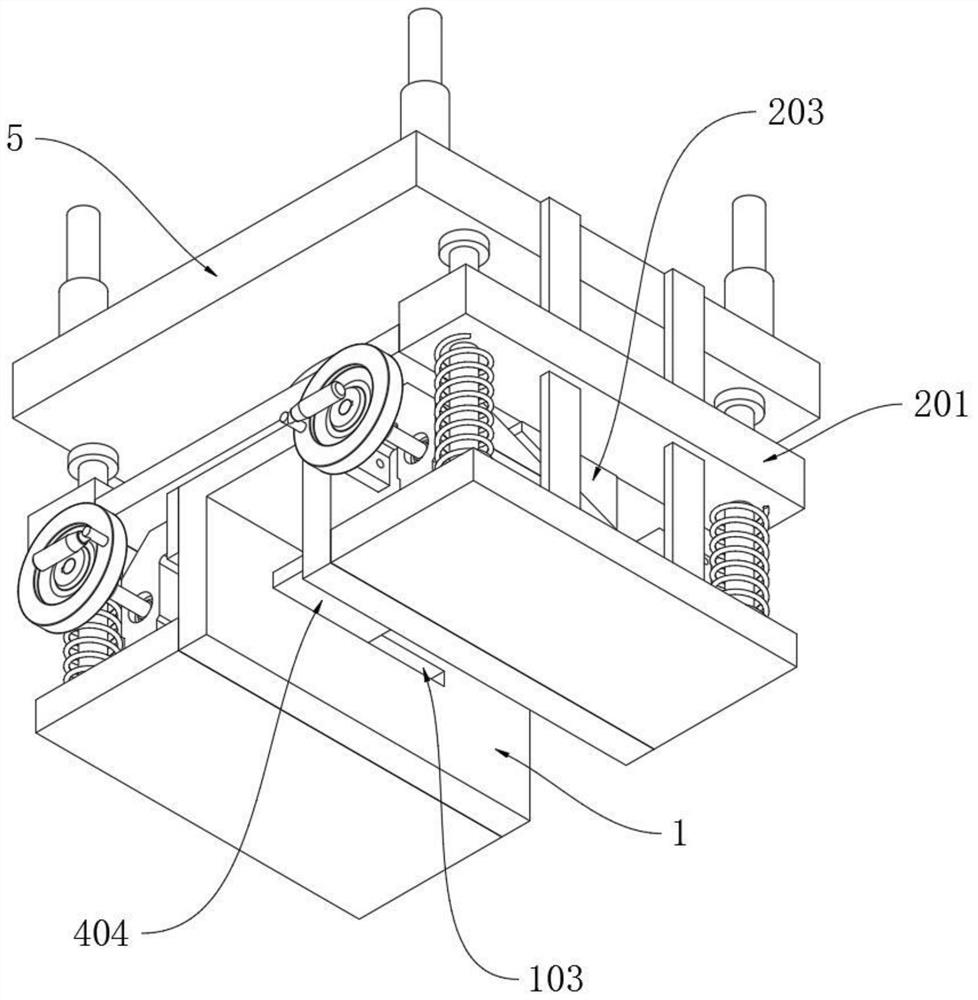

[0032] as attached figure 1 To attach Figure 8 Shown:

[0033] The invention provides a detachable lower ball seat for a high-speed bridge swivel steel bearing, which includes a lower ball seat 1; a lower ball joint 2 is installed horizontally on the upper end of the lower ball seat 1; 7. The upper ball joint 5 is connected in rotation; the left and right edges of the lower ball joint 2 are respectively vertically plugged with two mutually parallel limiting plates 6; Mechanism 4, jacking mechanism 4 comprises screw rod 401, hand wheel 402, squeeze block 403, Unicom plate 404 and guide clamping plate 405, and the middle part of jacking mechanism 4 is longitudinally screwed with screw rod 401, and the front end of screw rod 401 is fixedly installed with hand Wheel 402, the middle part of screw rod 401 is screwed with squeeze block 403, and the upper end of squeeze block 403 is a wedge-shaped structure, and the upper end of its squeeze block 403 is adapted to self-unloading bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com