A space transmission system that maintains continuous delivery

A space transmission and continuous technology, applied in the system field, can solve the problems of shortened conveying distance, large installation space, and large space occupation, and achieve the effect of shortening conveying distance, saving installation area and higher safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

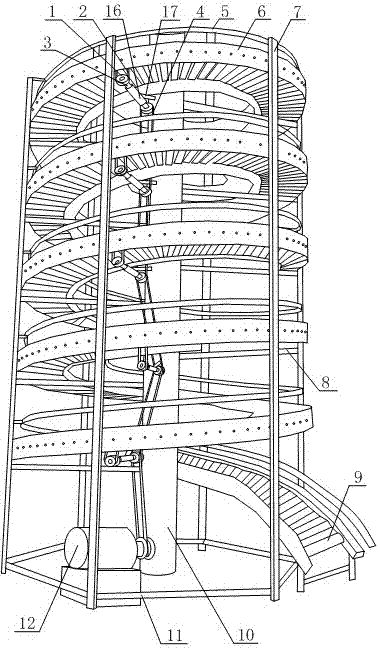

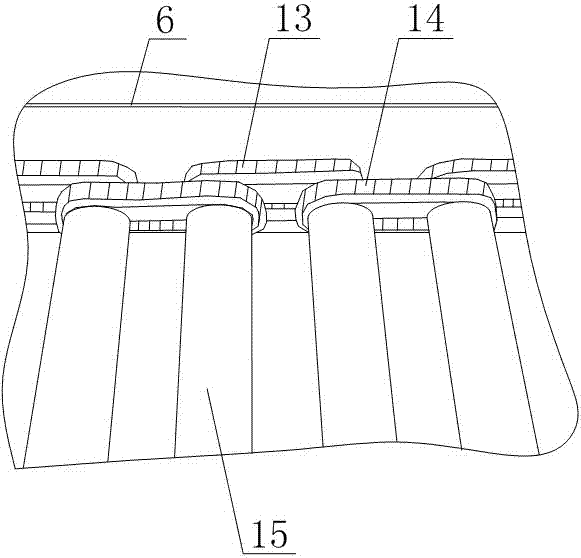

[0013] Such as figure 1 , figure 2 As shown, a space transmission system that maintains the continuity of transportation includes a column 10, the outer wall of the column 10 is provided with a screw conveying mechanism 9, and the screw conveying mechanism 9 is wound around the outer wall of the column 10, and the two sides of the screw conveying mechanism 9 The ends corresponding to the columns 10 are arranged at the same level. The screw conveying mechanism 9 is mainly composed of two spiral belts 6 arranged in parallel at the same height. Several rollers 15 are arranged between the spiral belts 6. The two ends of the roller 15 pass through the corresponding spiral belt 6 respectively, and the roller 15 can rotate in the spiral belt 6 around their respective axes, and a gear is fitted on the outer wall of the roller 15, and two adjacent rollers 15 form each The roller group, the roller 15 in the roller group is provided with a chain one 14, and the chain one 14 is meshed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com