Dustproofing vacuum feeding device for synthesized resin latex coating of outer wall

A synthetic resin emulsion and exterior wall coating technology, which is applied in transportation, packaging, conveyors, etc., can solve the problems of environmental pollution, dust scattering, etc., and achieve the effect of low renovation cost, simple structure, and good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

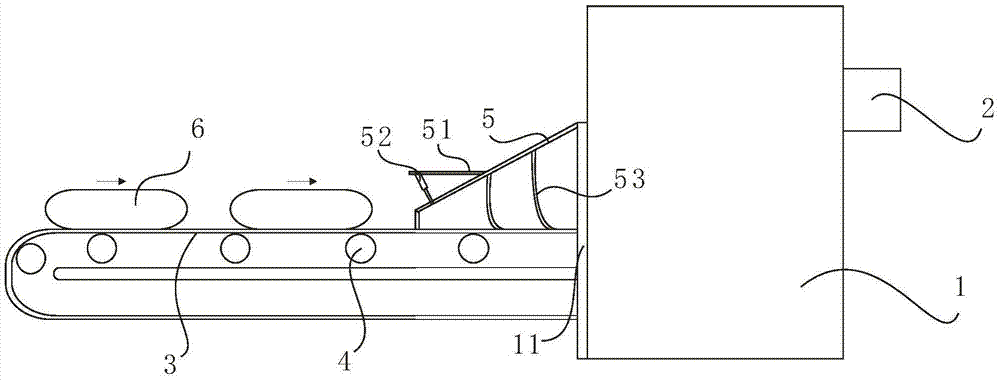

[0011] Such as figure 1 Shown is a vacuum feeding and dustproof device for synthetic resin emulsion exterior wall paint, which is characterized in that it includes feeding equipment 1 and a conveyor belt 3. The feeding equipment 1 is provided with a feeding port 2; Shaft 4; the feeding device 1 has a transmission port 11 for the conveyor belt 3 to enter; the transmission port 11 is provided with a dust cover 5 above the conveyor belt 3, and the dust cover 5 is on the front of the conveyor belt A feed window 51 that can be raised is provided above, and the feed window 51 is connected to the side of the dust cover 5 through an air pressure push rod 52 .

[0012] Furthermore, at least one drape 53 is arranged inside the dustproof cover 5 above the conveyor belt 3, and the upper end of the drape 53 is fixedly connected with the dustproof cover.

[0013] The working process of the present invention is to lift the feed window 51 of the dust cover 5 first, and the air pressure eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com