Elevator electric generating device

A self-generating and elevator technology, applied in electromechanical devices, elevators in buildings, electrical components, etc., can solve the problems of low power generation of generator motors, low speed of generator motors, and inability to make good use of elevator gravitational potential energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

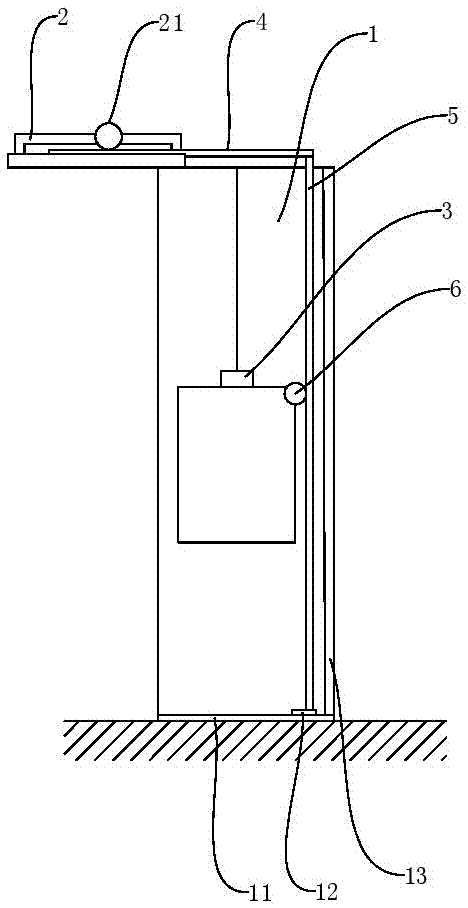

[0014] The reference signs in the accompanying drawings of the description include: car shaft 1, support frame 2, tension sensor 3, first gear 21, connecting rod 4, gear rod 5, second gear 6, chute 11, slider 12, concave Slot 13.

[0015] The embodiment is basically as attached figure 1 Shown: an elevator self-generating device, including a car shaft 1, a support frame 2 fixed above the car shaft 1, a tension sensor 3 arranged between the car and the wire rope, a single-chip microcomputer electrically connected to the tension sensor 3, and a power generation part; The support frame 2 is provided with a stepping motor connected with the single-chip electromechanical, the stepping motor is provided with a first gear 21, the support frame 2 is provided with a connecting rod 4 that is slidably connected with the support frame 2, and the connecting rod 4 is provided with a T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com