A multi-stage steel composite concrete pipe pile and its production device

A technology for concrete pipe piles and production equipment, which is applied in the direction of clay preparation equipment, mixing operation control equipment, and supply equipment. It can solve the problems of non-adjustable height, bulky support mechanism, and component ratio error, and achieve convenient disassembly, transportation, and support. Stable and reliable, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

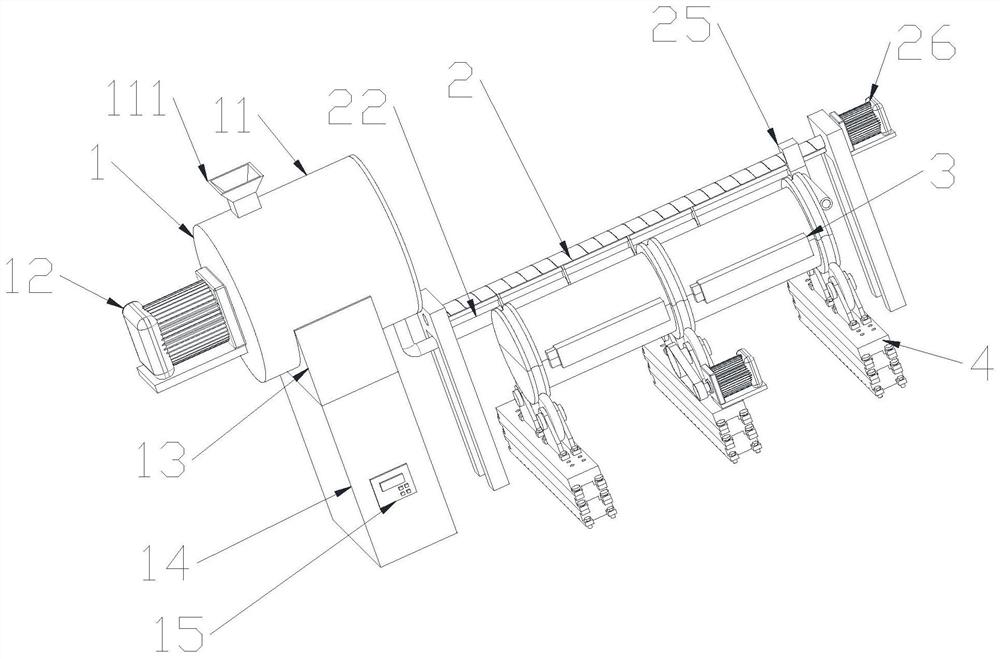

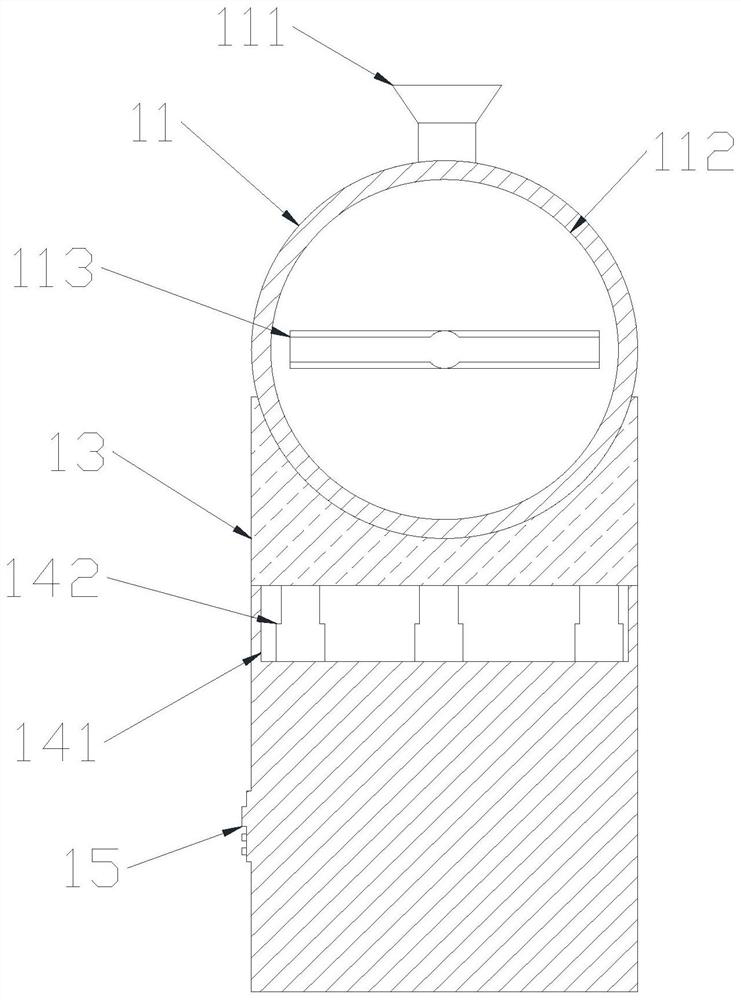

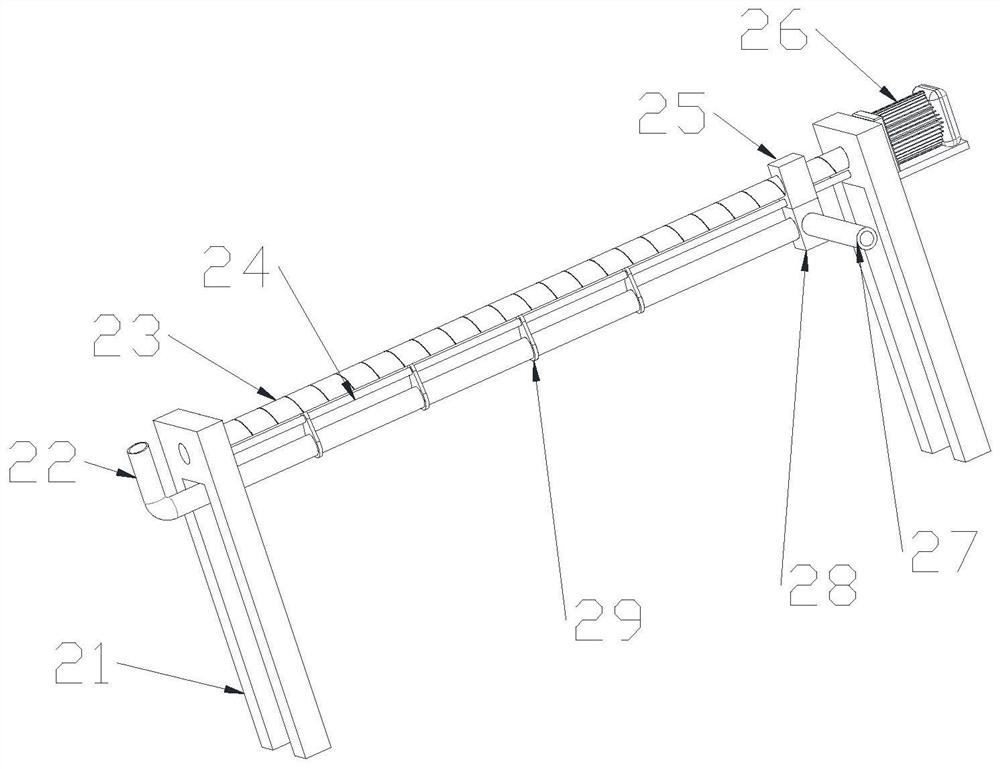

[0036] The multi-graded steel composite concrete pipe pile is to improve the mechanical properties of concrete by adding various raw materials such as gravel and stones to the concrete raw materials, and add prestressed and stretched steel bars to the mold during the production of concrete pipe piles to further Improve the mechanical properties of concrete pipe piles. Compared with traditional concrete pipe piles, the mechanical properties of concrete can be flexibly changed by adjusting the components of raw materials, which is suitable for different application scenarios. The invention designs a multi-gradation steel composite concrete pipe pile and a production device thereof, which can improve the production efficiency of the multi-gradation steel composite concrete pipe pile and is suitable for producing multi-gradation steel composite concrete pipe piles of different sizes. The specific implementation is as follows:

[0037] A multi-stage steel composite concrete pipe p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com