Low surface tension PBT resin

A technology of PBT resin and low surface tension, which is applied in the field of engineering plastics to achieve low surface tension characteristics and good separation effects

Pending Publication Date: 2016-03-30

JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, there is no literature report on PBT resin with low surface tension, so it is necessary to study a PBT resin with low surface tension to expand its application range

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

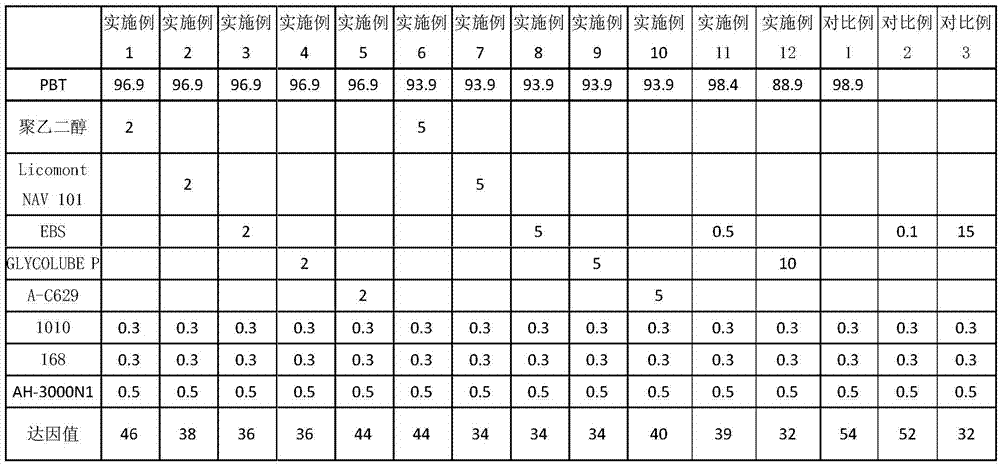

Embodiment 1-12 and comparative example 1-3

[0033] According to the formula in Table 1, mix PBT resin, surface tension modifier and other additives in a high-speed mixer for 1-2 minutes to obtain a premix, and the premix is passed through a twin-screw extruder at 220°C-240°C It can be obtained by melt extrusion, cooling and granulation. The surface tension test results are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention discloses a low surface tension PBT resin, which comprises, by weight, 78-99 parts of a PBT resin and 0.5-10 parts of a surface tension modifier, wherein the surface tension modifier is at least one selected from polyethylene glycol, oxidized polyethylene wax, stearate, a metallic soap salt and stearamide. According to the present invention, the low surface tension PBT resin has significant lower surface tension properties, can be well separated from the target substance, and can replace the TPX resin so as to be widely used as the LED packaging mold in the electronics packaging industry.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, in particular to a low surface tension PBT resin. Background technique [0002] Polybutylene terephthalate (PBT) is a semi-crystalline engineering plastic with good mechanical properties, electrical properties, heat resistance and chemical resistance, etc. It is widely used in automobiles, electronics, electrical appliances and other industries . However, PBT still has shortcomings. For example, when it is applied in the field of thin films, the surface tension of PBT resin is very high, and it is difficult to separate it from the target, thus limiting its application in the field of thin films. [0003] The film on the market mainly uses poly(4-methylpentene) TPX, which has a very low surface tension and can be separated from the target object. It is widely used as an LED packaging mold in the electronic packaging industry. [0004] At present, there is no literature report on PBT...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L67/02C08L71/02C08L23/30C08K5/098C08K5/20C08K5/103

CPCC08L67/02C08K5/098C08K5/103C08K5/20C08L2203/206C08L71/02C08L23/30

Inventor 殷年伟卢立波张大鹏林沫然易新

Owner JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com