Ketone-hydrazine crosslinking type water-based fluoride-free fabric waterproof finishing agent as well as preparation method and application thereof

A waterproof finishing and cross-linking technology, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of unsatisfactory waterproof effect and poor durability, achieve lasting excellent waterproof effect, improve durability, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

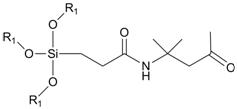

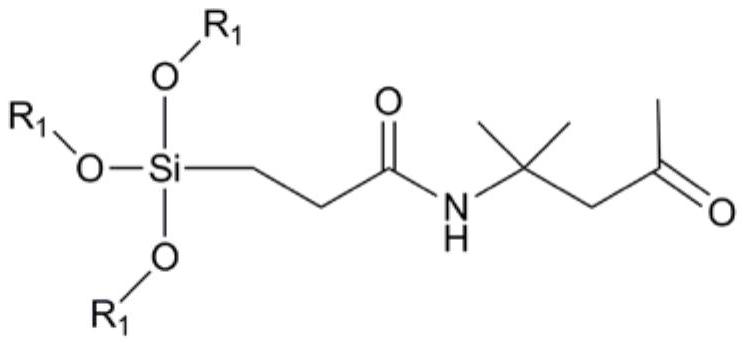

[0027] The preparation method of organosilicon modified waterborne polyurethane comprises the following steps:

[0028] S1. Mix hydroxyl-terminated polysiloxane, polyethylene glycol, dimethylol propionic acid and isophorone diisocyanate, and react at 60-90° C. for 3-8 hours under the action of a catalyst to obtain a prepolymer. The catalyst here can be an amine catalyst or an organic metal catalyst, such as an organic bismuth compound.

[0029] S2. After the temperature of the reaction system drops to 25-30°C, add triethylamine to neutralize the reaction for 25-30 minutes. The added amount of triethylamine here is equimolar with the dimethylolpropionic acid added in S1.

[0030] S3. Slowly add deionized water to the product of the S2 reaction, emulsify at a high speed at 2000-2500rpm for 30-50min, then add adipic acid dihydrazide to seal the remaining active isocyanate groups in the system, and obtain silicone modified Waterborne polyurethane emulsion, the effective content ...

Embodiment 1

[0043] This embodiment provides a silicone-modified polyurethane and a preparation method thereof, comprising the following steps:

[0044] S1. Weigh 225g of hydroxyl-terminated polysiloxane, 76g of polyethylene glycol, 69g of dimethylol propionic acid and 190g of isophorone diisocyanate, mix it with the catalyst and stir at a speed of 100rpm And heated to 85 ° C, the reaction 3h. The viscosity of the hydroxyl-terminated polysiloxane used in this embodiment is 700 mPa.s, and the polyethylene glycol is PEG1000.

[0045] S2. After the temperature of the reaction system drops to 25° C., add 52 g of triethylamine for neutralization reaction for 30 minutes.

[0046] S3. Slowly add 1205g of deionized water to the product of S2 reaction, emulsify at a high speed of 2000rpm for 30min, then add 50g of adipic acid dihydrazide to seal the remaining active isocyanate groups in the system, and obtain a silicone-modified Emulsion of waterborne polyurethane.

Embodiment 2

[0048] The main difference between this example and Example 1 is that in S1 of this example, 250g of hydroxyl-terminated polysiloxane, 110g of polyethylene glycol, 127g of dimethylol propionic acid and 310g of isofor Alone diisocyanate was reacted at 80°C for 4h. The polyethylene glycol used in this embodiment is PEG800. In S2, 96 g of triethylamine was added to react at 30° C. for 25 min. In S3, continue to add 1920g of water, high-speed emulsification at 2500rpm for 40min, and then add 60g of adipic acid dihydrazide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com