Oil-based lubricating anti-seize agent used in well drilling, and preparation method and applications thereof

An anti-sticking agent and lubricant technology, applied in the field of oil drilling, can solve the problems of low lubricating performance of the sticking-releasing agent, poor effect of removing the sticking agent, easy to drill again, etc., so as to improve lubricity, reduce logging interference, reduce The effect of sticking risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

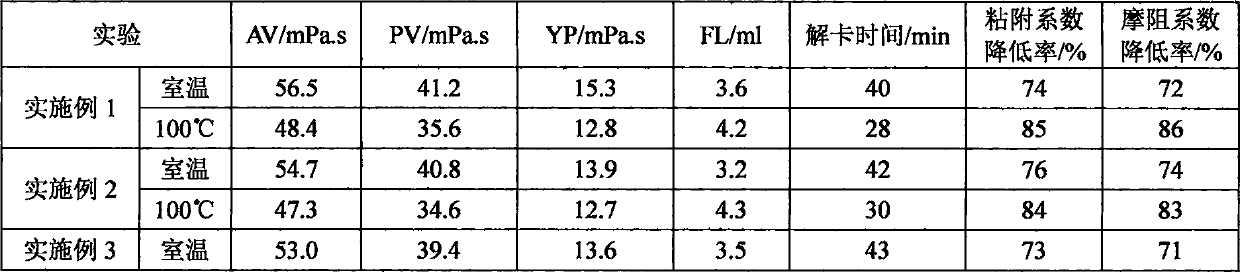

Embodiment 1

[0027] Step 1: Mix castor oil, concentrated sulfuric acid and diethanolamine according to the weight ratio of 60:1:3, and the reaction temperature is controlled at 110°C. After reacting for 3 hours, continue to add fatty acid methyl ester and nitric acid with a weight ratio of 60:5, The reaction temperature was controlled at 100° C., and after 2 hours of reaction, it was cooled to room temperature to obtain a liquid lubricant.

[0028] Step 2: Dissolve 10 parts of low-fluorescent sulfonated asphalt in 80 parts of castor oil at room temperature. After fully stirring, add 12 parts of lubricant prepared in step 1, 2 parts of accelerator, polyoxyethylene alkyl ether phosphate After fully dissolving, add 10 parts of sodium succinate and 3 parts of ZnO nanoparticles in sequence, continue stirring, and finally add 4 parts of formate, stir and stand to obtain a stable system.

Embodiment 2

[0030] Step 1: palm oil, concentrated sulfuric acid and diethanolamine are mixed according to the weight ratio of 80:6:5, and the reaction temperature is controlled at 130°C. After reacting for 4 hours, continue to add fatty acid methyl ester and nitric acid with a weight ratio of 100:10, The reaction temperature was controlled at 110° C., and after 2 hours of reaction, it was cooled to room temperature to obtain a liquid lubricant.

[0031] Step 2: Dissolve 15 parts of low-fluorescent sulfonated asphalt in 90 parts of palm oil at room temperature, and after fully stirring, add 14 parts of lubricant prepared in step 1, 3 parts of accelerator, polyoxypropylene alkyl ether phosphate 4 parts, after fully dissolving, add 15 parts of sodium succinate, LiTaO 3 5 parts of nanoparticles, continue to stir, and finally add 4 parts of formate, stir and stand to obtain a stable system.

Embodiment 3

[0033] Step 1: Mix soybean oil, concentrated sulfuric acid and diethanolamine according to the weight ratio of 90:11:10, and control the reaction temperature at 140°C. After reacting for 5 hours, continue to add fatty acid methyl ester and nitric acid with a weight ratio of 160:20, and react The temperature was controlled at 120° C., and after reacting for 3 hours, it was cooled to room temperature to obtain a liquid lubricant.

[0034] Step 2: Dissolve 20 parts of low-fluorescence sulfonated asphalt in 100 parts of soybean oil at room temperature, and after fully stirring, add 15 parts of lubricant prepared in step 1, 4 parts of accelerator, and 5 parts of polyoxyethylene alkyl ether phosphate After fully dissolving, add 20 parts of sodium succinate, KNbO 3 6 parts of nanoparticles, continue to stir, and finally add 5 parts of formate, stir and stand to obtain a stable system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com