Assembled corrugated slab foundation to prevent local settlement

A local settlement and assembly technology, applied in infrastructure engineering, construction, etc., can solve the problems of time-consuming and laborious, uneven foundation settlement adaptability, and high construction difficulty, so as to shorten the construction period, prevent uneven settlement, and reduce construction difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

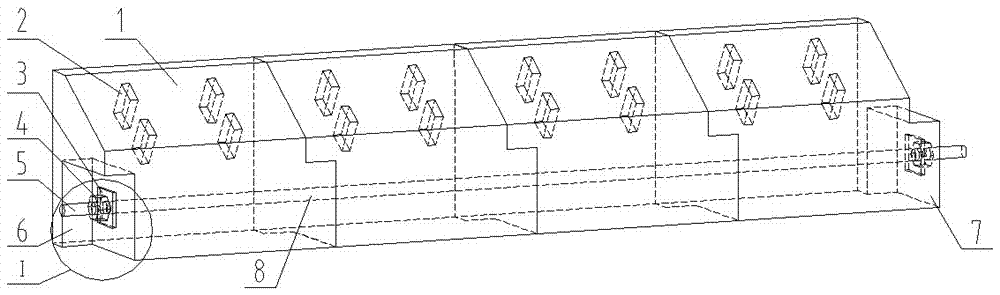

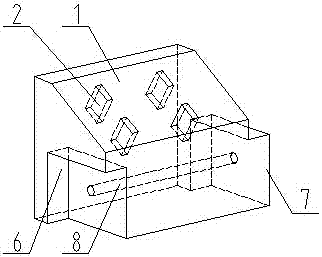

[0028] The invention relates to an assembled corrugated culvert foundation for preventing partial settlement, which has the characteristics of preventing partial settlement, reliable connection, strong versatility, convenient construction and the like, and is suitable for corrugated culvert and similar corrugated culvert structures.

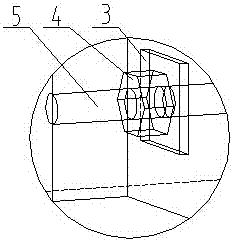

[0029] According to the actual length of the corrugated culvert, the foundation is composed of a plurality of foundation blocks 1 assembled, one end of the foundation block 1 is provided with a groove 6 , and the other end is provided with a boss 7 matching with the groove 6 . In the direction of the longitudinal axis of the corrugated culvert, the adjacent foundation blocks 1 are arranged in occlusion through the mutual positioning of the grooves 6 and the bosses 7 . The shape of the groove 6 and the boss 7 is a cube, a cuboid or a cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com