A heat-insulating high-speed rail window aluminum alloy profile

A technology of aluminum alloy profiles and aluminum materials, which is applied in the direction of railway car body parts, windows/doors, window devices, etc., can solve the problems of poor sound insulation effect, poor strength and variability of aluminum profile frames, and achieve increased strength and load bearing Ability, strong structural connection, good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

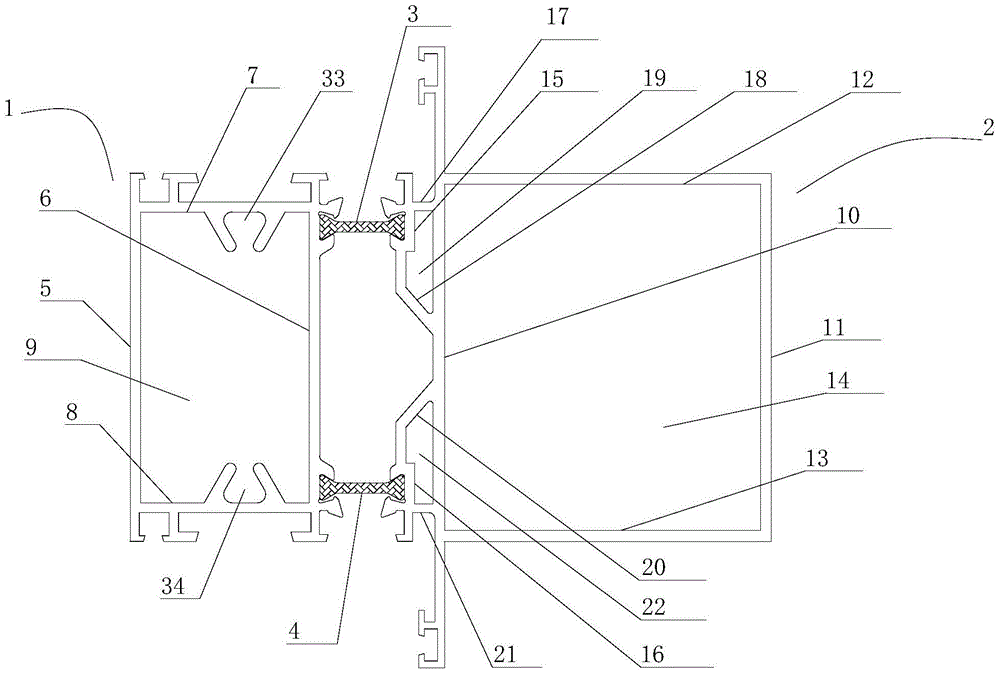

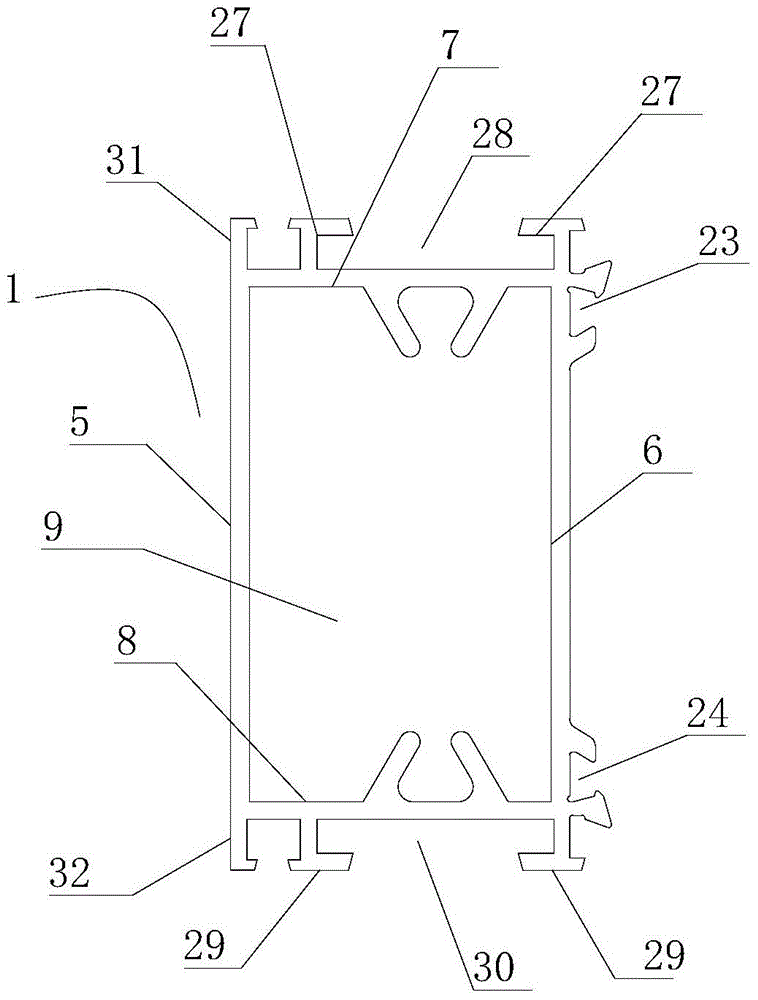

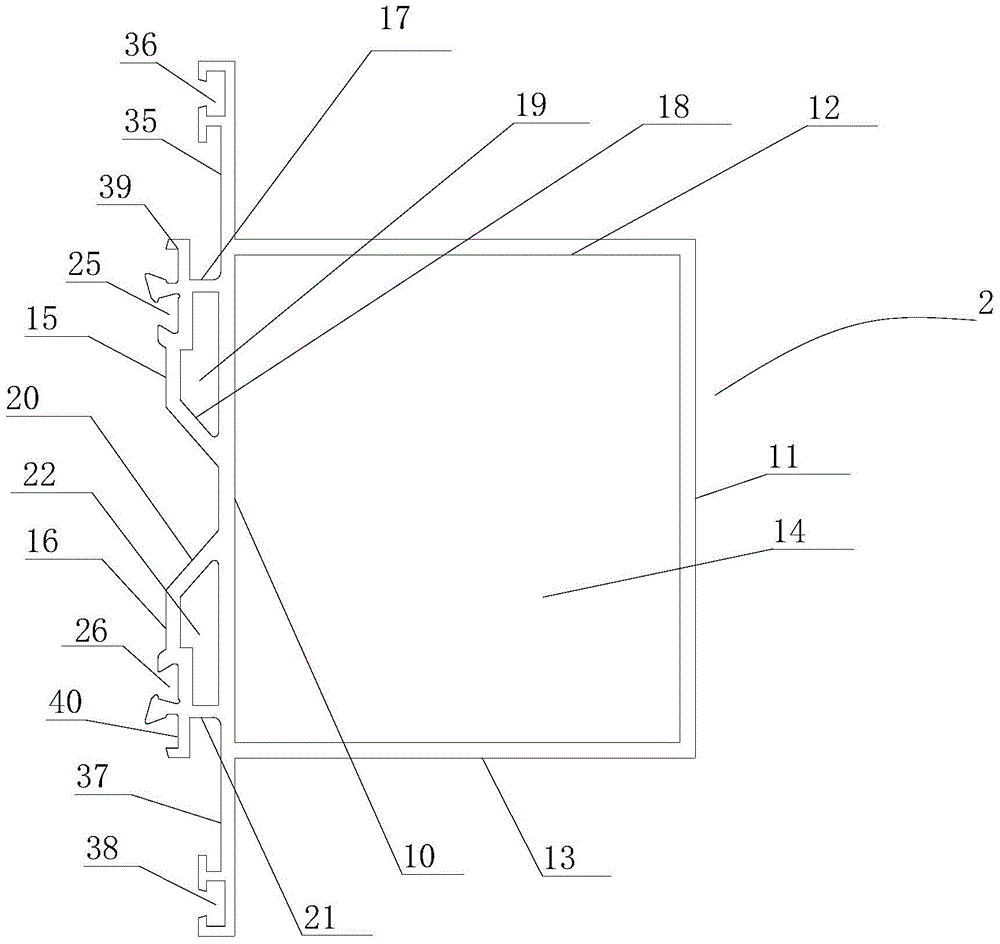

[0022] refer to figure 1 , figure 2 , image 3 , the present invention proposes a heat-insulating high-speed rail window aluminum alloy profile, including a stile, and the stile includes a first profile body 1, a second profile body 2, and a connecting rod for connecting the first profile body 1 and the second profile body 2 The first heat insulation strip 3, the second heat insulation strip 4, wherein:

[0023] The first profile body 1 includes a first aluminum plate 5 and a second aluminum plate 6 that are oppositely arranged, and a third aluminum plate 7 and a fourth aluminum plate are passed between the first aluminum plate 5 and the second aluminum plate 6. The plates 8 are connected, the third aluminum plate 7 and the fourth aluminum plate 8 are set horizontally, the first aluminum plate 5, the third aluminum plate 7, the second aluminum plate 6, and the fourth aluminum plate 8 A first abdominal cavity 9 is formed, and the cross section of the first abdominal cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com