Pneumatic-hydraulic pressure cylinder with multiple times of prepressing and pressure boosting and working method thereof

A gas-liquid booster cylinder, booster cylinder technology, applied in the direction of fluid pressure converters, mechanical equipment, etc., can solve the stamping process requirements that can only be preloaded, boosted and returned, but cannot meet the requirements of preloading and boosting, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

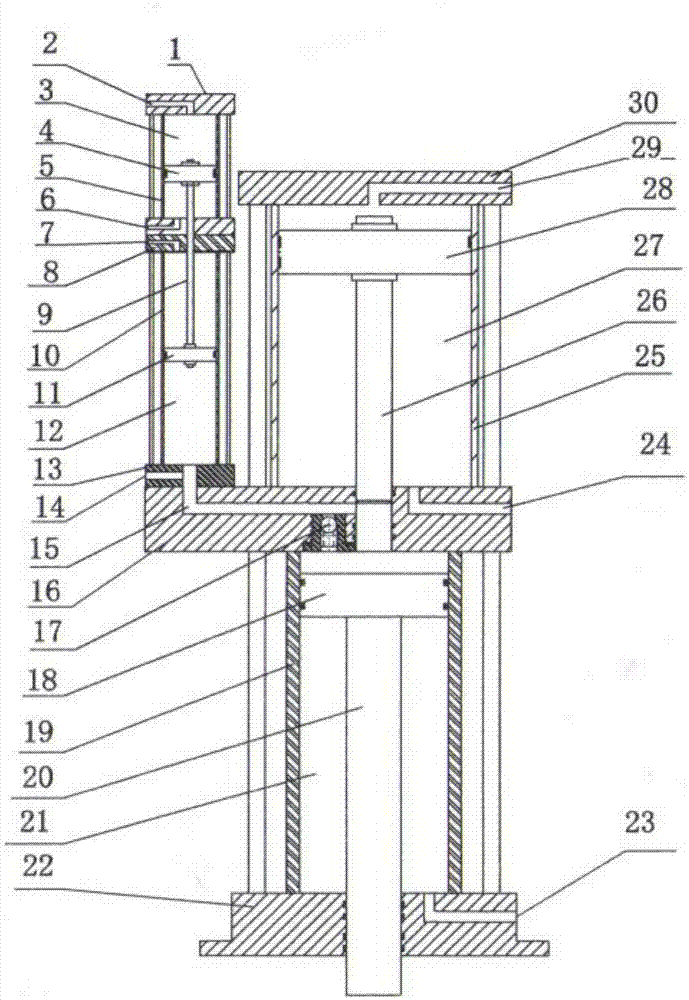

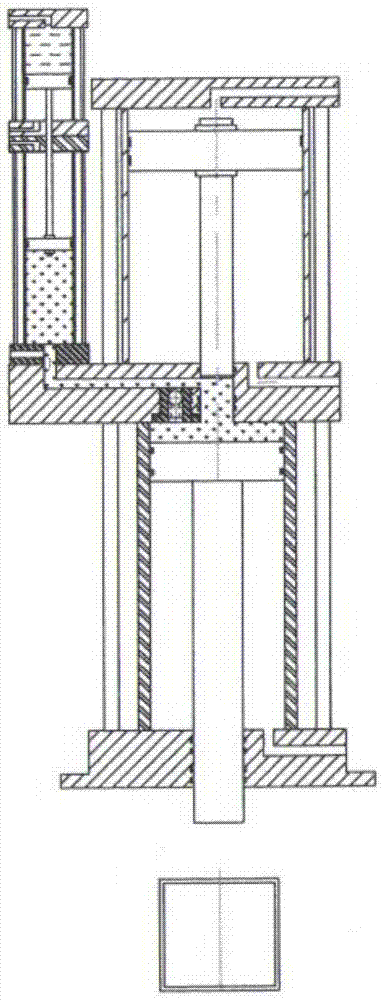

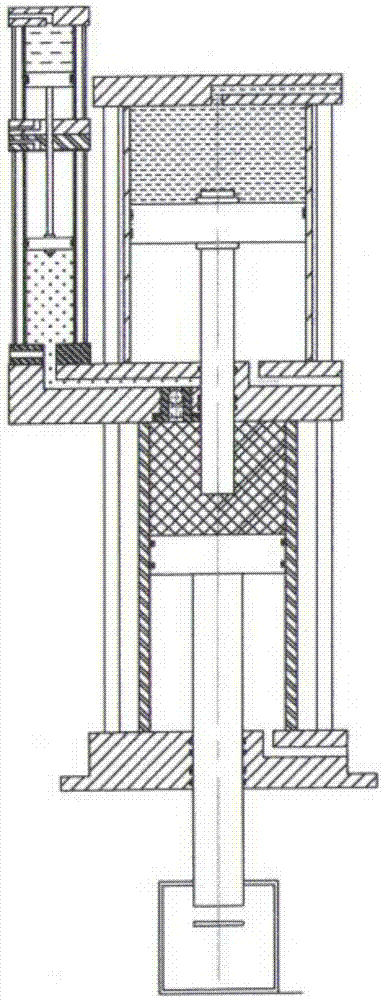

[0028] as attached figure 1 , a gas-liquid booster cylinder with multiple preloading and boosting, including a cylinder 3, an oil injection cylinder 12, a booster cylinder 27 and an oil cylinder 21, the cylinder 3 is connected in series with the oil injection cylinder 12, and the oil injection cylinder 12 is respectively Connect (pass) with the first preload of oil cylinder 21, and connect (pass) with oil cylinder 21 one-way oil inlet and preload again through one-way oil inlet device (check valve 17); Pressure connection (through); the oil cylinder 21 is suspended above the working surface for multiple pre-pressurization and boosting.

[0029] The cylinder 3 is arranged above the oil injection cylinder 12, and the top of the cylinder 3 is provided with a cylinder upper cover 1, and the cylinder 3 and the oil injection cylinder 12 are connected by a shared cylinder mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com