Constant-velocity joint

一种等速接头、接触区的技术,应用在速接头领域,能够解决滑动阻力增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

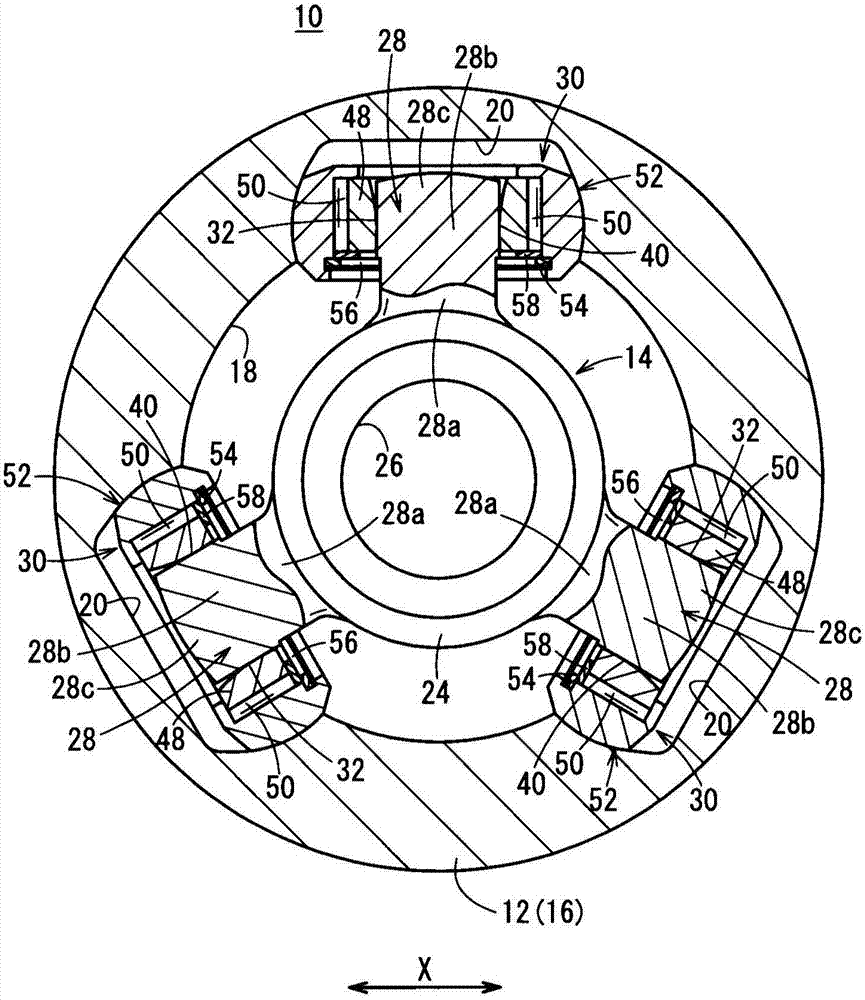

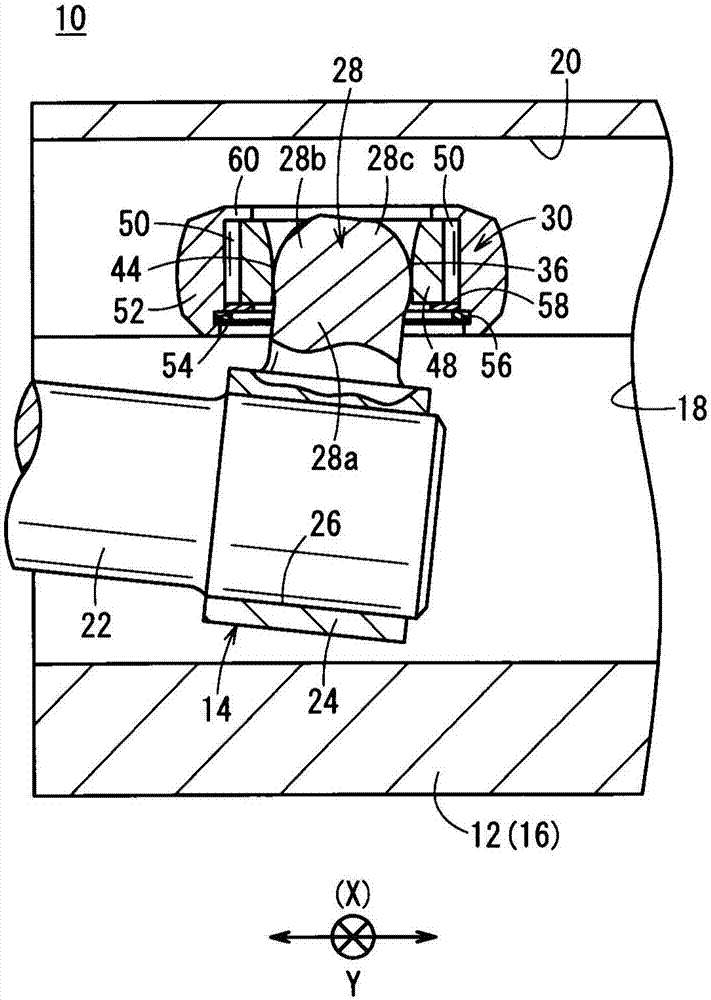

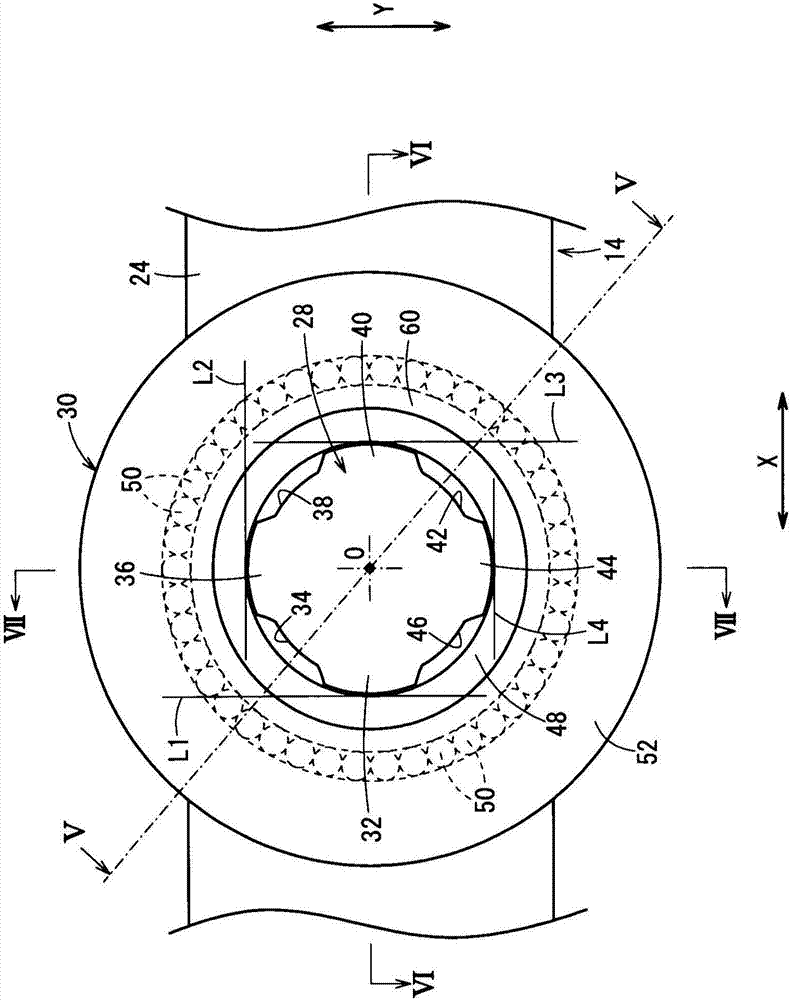

[0028] Hereinafter, a constant velocity joint according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0029] figure 1 A constant velocity joint 10 according to an embodiment of the invention is shown in cross section, the view being taken along a line perpendicular to the axial direction of the constant velocity joint. figure 2 The constant velocity joint is shown in a fragmentary sectional side view along the axial direction of the constant velocity joint. exist figure 1 , arrow X indicates the width direction or lateral direction of the outer member 12 . exist figure 2 , arrow Y indicates the longitudinal direction of the constant velocity joint 10 . The X direction and the Y direction are perpendicular to each other.

[0030] The constant velocity joint 10 includes an outer member 12 and an inner member 14 . The outer member 12 has a bottomed cup portion 16 and an unillustrated shaft pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com