Delay element test device and method

A technology of extension body and cavity, which is used in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of high test cost, long time period, and hidden safety hazards, so as to reduce the accident rate, reduce test errors, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the above.

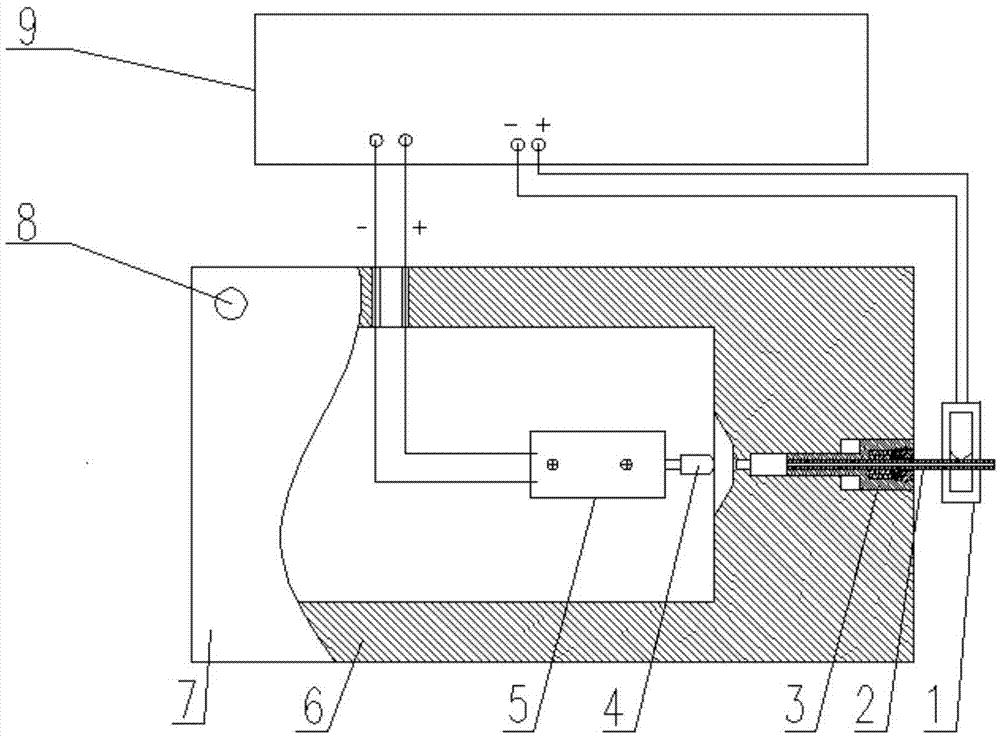

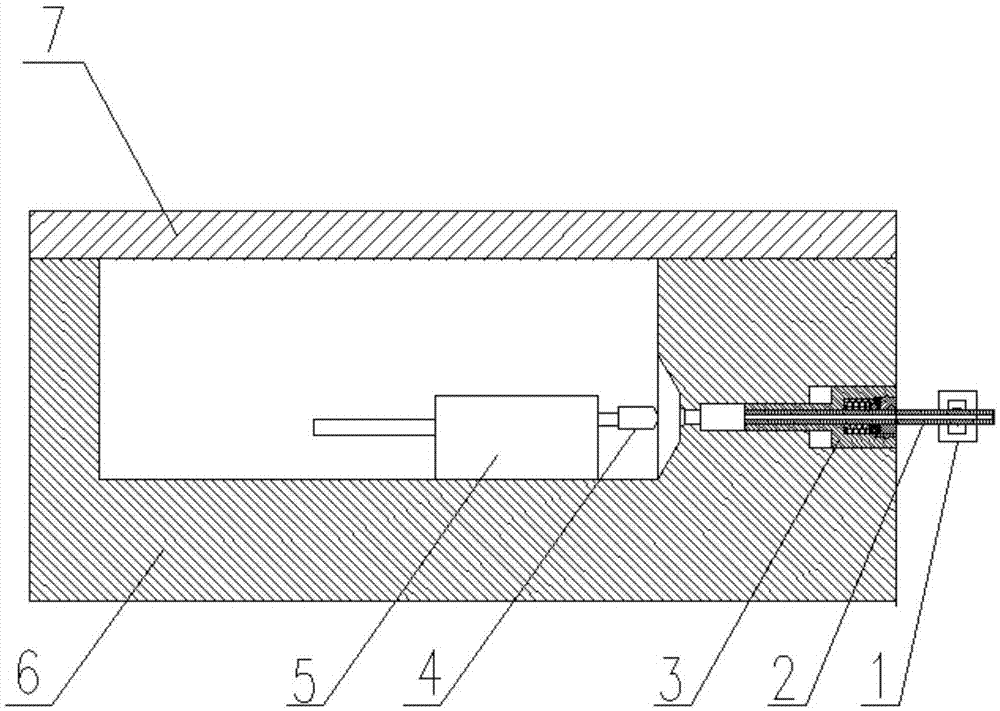

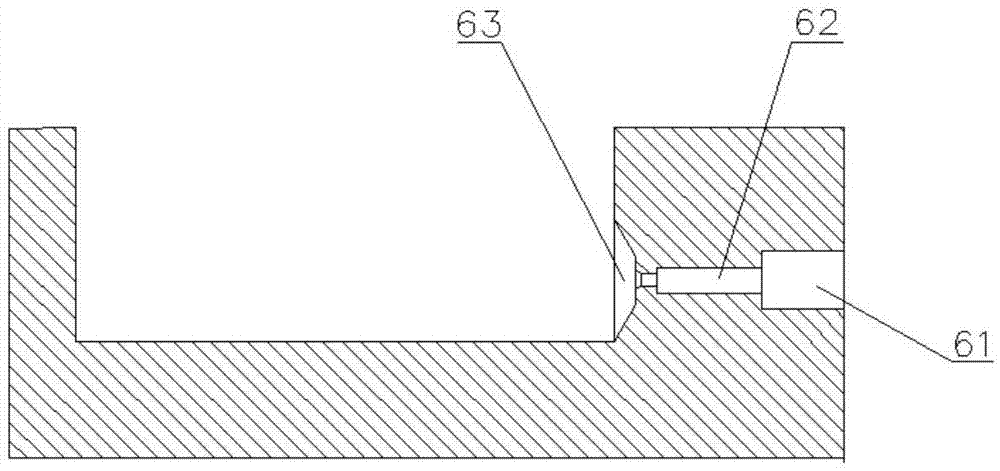

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A device for deferred body testing shown includes a base 6, a signal processor 9, a signal detector 1, a cover plate 7, a detonating tube 2, a quick connection device 3, and an operational amplifier 5, a signal detector 1 and an operational amplifier 5 are respectively connected to the signal processor 9, the signal detector 1 is installed on the detonating tube 2, the operational amplifier 5 is installed on the inner wall of the base 6, and the base 6 is a square cavity structure with an upper opening and a bottom sealed, the cover plate 7 is installed at the upper edge of the base 6. The side wall of the base 6 is sequentially provided with a connecting mounting hole 61, a filling chamber 62, and a photometric hole 63 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com