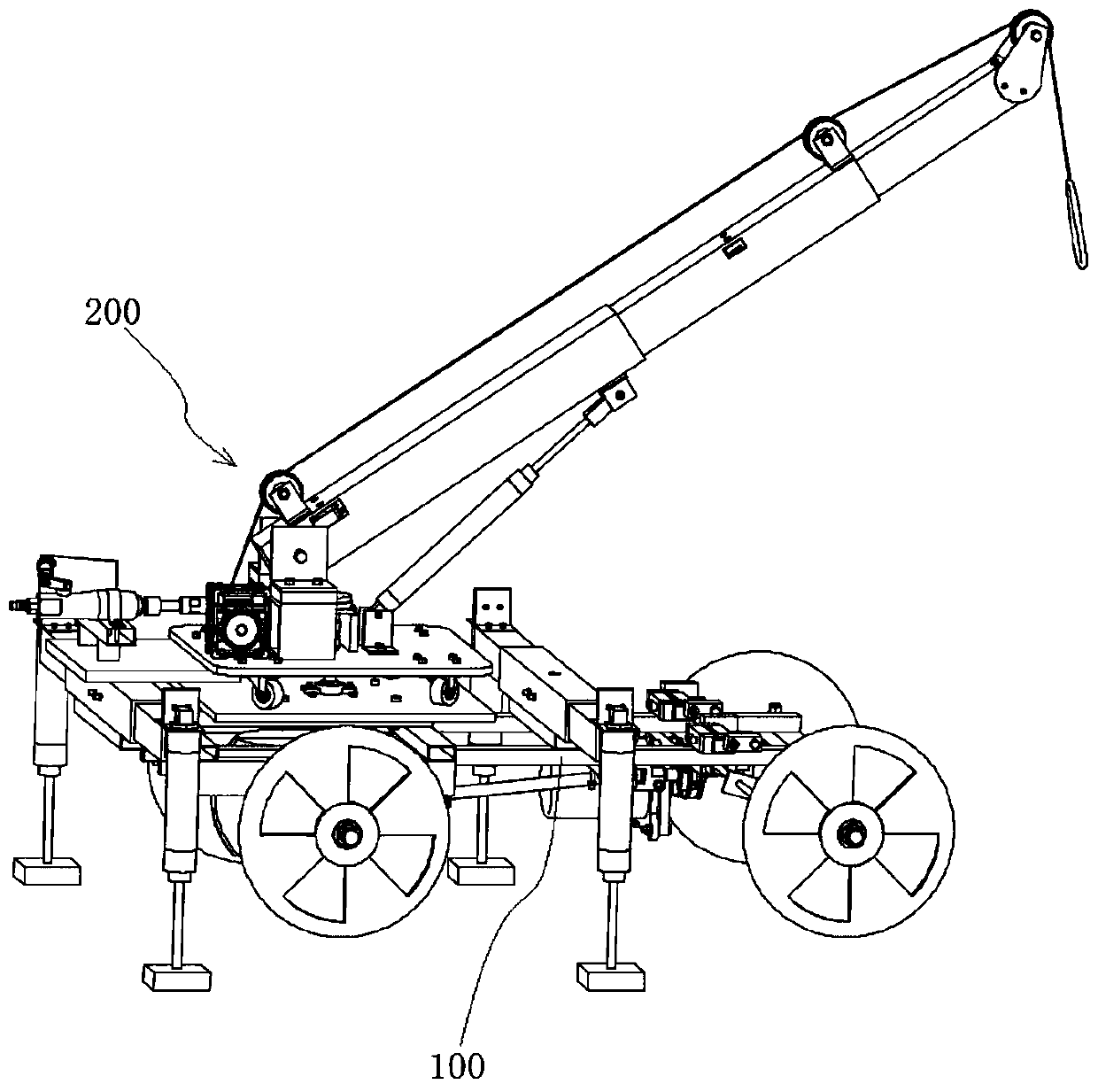

A car chassis of a pneumatic car crane

A pneumatic vehicle and vehicle chassis technology, applied in simulators, space navigation condition simulation devices, instruments, etc., can solve the problems of large volume and complex structure of truck cranes, achieve low production cost, simple structure realization, and improve learning interest Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

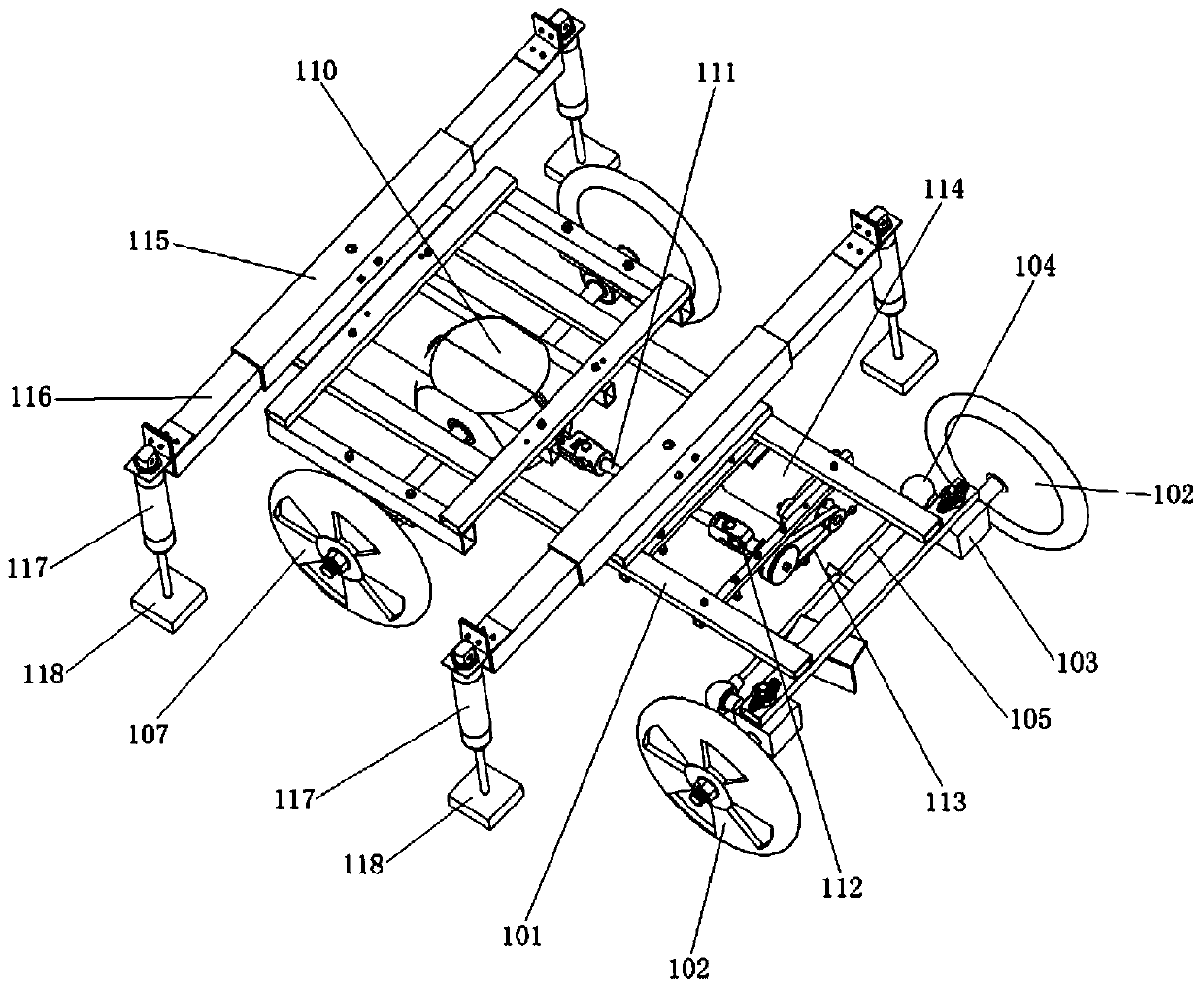

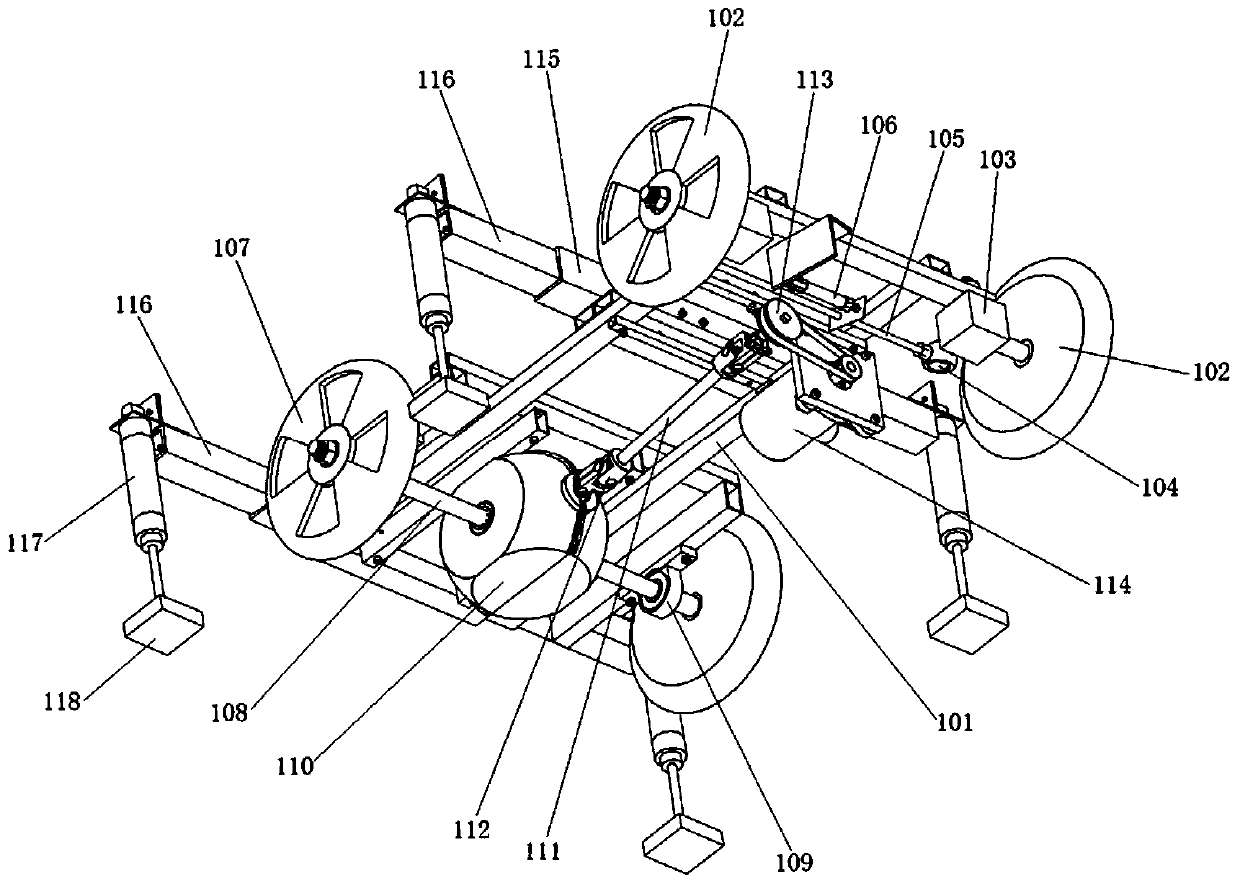

[0028] to combine figure 2 and image 3 As shown, the automobile chassis of a kind of pneumatic truck crane of the present embodiment comprises a vehicle frame 101, two front wheels 102 installed on the front end of the vehicle frame 101 through the front axle, and two rear wheels 102 installed on the rear end of the vehicle frame 101 through the rear axle. Wheels 107, two sets of lifting legs mounted on the vehicle frame 101, steering cylinders 106 for controlling the steering of the front wheels 102, and wind motors 114 for driving the rear wheels 107 to rotate. The vehicle frame 101 adopts a welded vehicle frame, which has a stable and reliable structure and high rigidity. The steering cylinder 106 is located between the vehicle frame 101 and the front axle, and the telescopic movement of the steering cylinder 106 drives the two front wheels 102 to deflect synchronously; The differential 110 in the bridge is connected, and the air motor 114 converts the gas pressure into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com