A new type of chip diode manufacturing process and its special welding mold

A manufacturing process and welding mold technology, applied in the field of new chip diode manufacturing process, can solve the problems of restricting the improvement of product electrical yield and production cost, and achieve the effects of low welding stress, improved utilization rate, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The new chip diode manufacturing process of this embodiment, the steps are as follows:

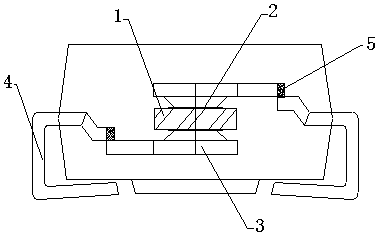

[0028] (1) if figure 1 As shown, the chip 1, the soldering piece 2 and the oxygen-free copper connecting piece 3 are precisely positioned using a special welding mold, so that the P pole connecting piece extends out of the P electrode of the chip horizontally, and the N pole connecting piece extends out of the N electrode of the chip horizontally; Then put the special welding mold in the tunnel furnace and weld at 360°C for 7 minutes. After the welding piece is melted, the P pole connecting piece, the N pole connecting piece and the chip form a stable Z-shaped structure;

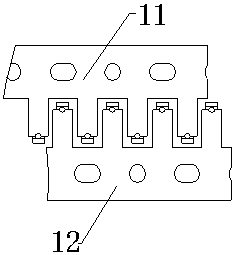

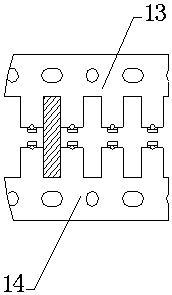

[0029] (2) The chip 1 welded with the connecting piece 3 is taken out by an intelligent manipulator and placed on the laser welding tool; then the frame 4 with several lead brackets distributed inside is placed on the corresponding laser welding tool; image 3 As shown, the lead end of the upper frame 11 is provi...

Embodiment 2

[0032] The new chip diode manufacturing process of this embodiment, the steps are as follows:

[0033] (1) if figure 1 As shown, the chip 1, the soldering piece 2 and the oxygen-free copper connecting piece 3 are precisely positioned using a special welding mold, so that the P pole connecting piece extends out of the P electrode of the chip horizontally, and the N pole connecting piece extends out of the N electrode of the chip horizontally; Then put the special welding mold in the tunnel furnace and weld at 375°C for 12 minutes. After the welding piece is melted, the P pole connecting piece, the N pole connecting piece and the chip form a stable Z-shaped structure;

[0034] (2) Take out the chip 1 welded with the connecting piece 3 through the intelligent manipulator, and place it on the laser welding tool; then place the frame 4 with several lead brackets distributed on the inside on the corresponding laser welding tool; image 3 As shown, the lead end of the upper frame 11...

Embodiment 3

[0037] The new chip diode manufacturing process of this embodiment, the steps are as follows:

[0038] (1) if figure 1 As shown, the chip 1, the soldering piece 2 and the oxygen-free copper connecting piece 3 are precisely positioned using a special welding mold, so that the P pole connecting piece extends out of the P electrode of the chip horizontally, and the N pole connecting piece extends out of the N electrode of the chip horizontally; Then put the special welding mold in the tunnel furnace and weld at 370°C for 10 minutes. After the welding piece is melted, the P pole connecting piece, the N pole connecting piece and the chip form a stable Z-shaped structure;

[0039] (2) Take out the chip 1 welded with the connecting piece 3 through the intelligent manipulator, and place it on the laser welding tool; then place the frame 4 with several lead brackets distributed on the inside on the corresponding laser welding tool; image 3 As shown, the lead end of the upper frame 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com