A method for coating LED fluorescent powder glue

A phosphor and LED module technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult to obtain the ideal phosphor powder shape, complex phosphor coating methods, etc., to improve the consistency of light color and cost Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

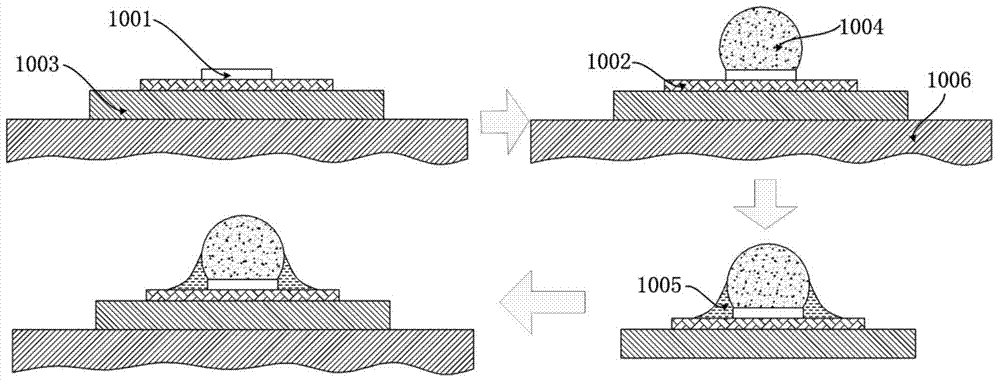

Method used

Image

Examples

Embodiment 1

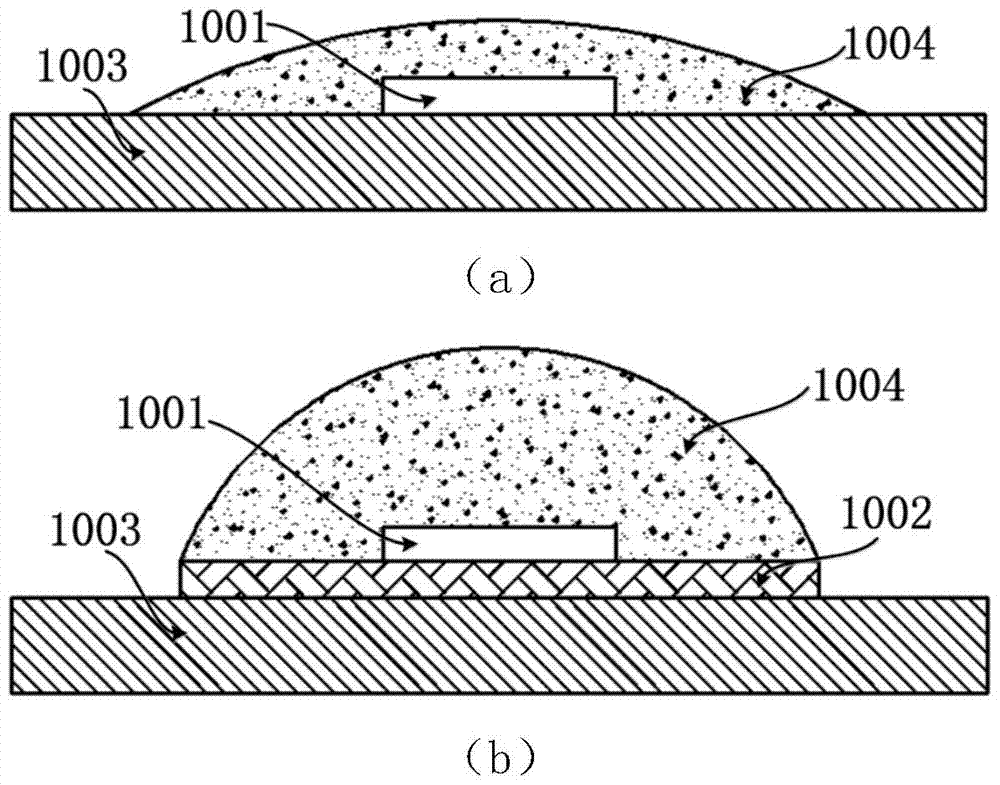

[0042] S1: Place the LED module that has completed the chip mounting and circuit connection on the heating plate. The LED chip is a rectangular chip, the thickness of the rectangular chip is 1 mm, and the length L and width W of the rectangular chip are both 3 mm. The ratio of the volume of phosphor glue coated on the upper surface of the chip to the area of the upper surface of the rectangular chip is (L+W) / 8, and the heating temperature of the LED module is 100°C.

[0043] S2: After the temperature of the LED module is stabilized at 100°C, apply 6.75 microliters of fluorescent powder glue with a set concentration of 0.02 g / ml on the upper surface of the chip, and stand still for a certain period of time until the set amount of phosphor powder is applied The glue forms a spherical-segment-like topography on the upper surface of the chip.

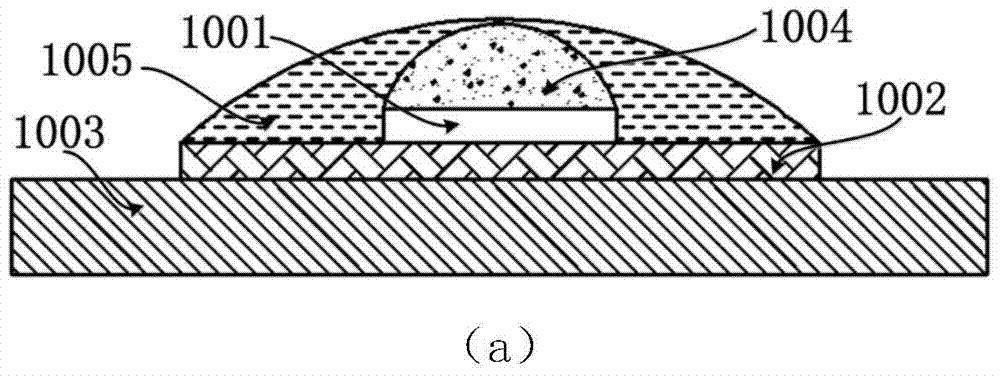

[0044] S3: Remove the LED module from the heating substrate, and apply 4.1 microliters of fluorescent powder glue with a set concentrati...

Embodiment 2

[0047] S1: Place the LED module that has completed the chip mounting and circuit connection on the heating plate. The LED chip is a rectangular chip, the thickness of the rectangular chip is 0.1 mm, and the length L and width W of the rectangular chip are both 1 mm. The ratio of the coating volume to the area of the upper surface of the rectangular chip was (L+W) / 2, and the heating temperature of the LED module was 150°C.

[0048] S2: After the temperature of the LED module is stabilized at 150°C, apply 1 microliter of fluorescent powder glue with a set amount of 1 g / ml on the upper surface of the chip, and stand still for a certain period of time until the set amount of phosphor powder is applied. The glue forms a spherical-segment-like topography on the upper surface of the chip.

[0049] S3: Remove the LED module from the heating substrate, and apply 0.8 microliters of phosphor glue with a set concentration of 1 g / ml on the side surface of the chip, and the concentration ...

Embodiment 3

[0052] S1: Place the LED module that has completed the chip mounting and circuit connection on the heating plate. The LED chip is a rectangular chip, the thickness of the rectangular chip is 0.01 mm, and the length L and width W of the rectangular chip are both 0.5 mm. The ratio of the coating volume to the area of the upper surface of the rectangular chip was 3(L+W) / 2, and the heating temperature of the LED module was 180°C.

[0053] S2: After the temperature of the LED module is stabilized at 180°C, apply 0.375 microliters of fluorescent powder glue with a set concentration of 4 g / ml on the upper surface of the chip, and stand still for a certain period of time until the set amount of phosphor powder is applied The glue forms a spherical-segment-like topography on the upper surface of the chip.

[0054] S3: Remove the LED module from the heating substrate, and apply 0.2 microliters of fluorescent powder glue with a set concentration of 5 g / ml on the side surface of the chi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap