Rotary shaft of permanent magnet motor and installation method thereof

A technology of permanent magnet motor and installation method, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of increasing the difficulty of magnetic bearing control, radial magnetic bearing interference, etc., to avoid thermal demagnetization, eliminate interference, The effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the invention, some specific details are set forth in detail. The present invention can be fully understood by those skilled in the art without the description of these detailed parts. To avoid obscuring the essence of the present invention, well-known methods, procedures, procedures, and components have not been described in detail.

[0035] The following defines the directions in this application as follows: the inner side is the side close to the axis of the rotating shaft in the radial direction, and the outer side is the side away from the axial direction of the rotating shaft; the end face is a surface located at one end in the axial direction and generally perpendicular to the axis of the rotating shaft .

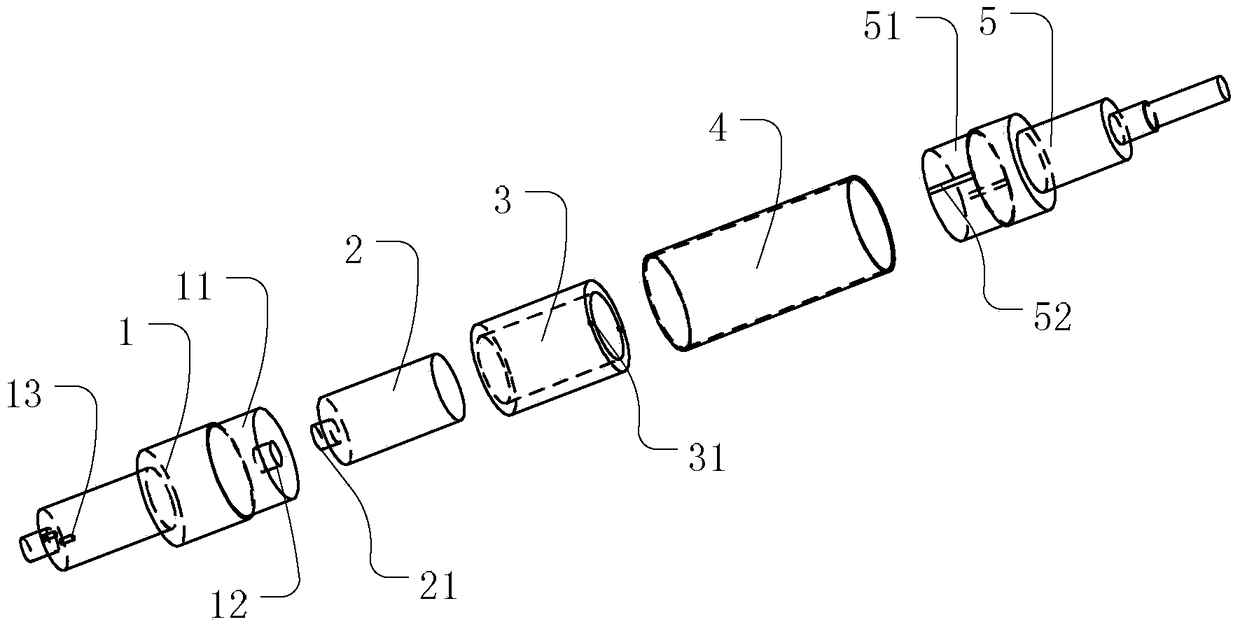

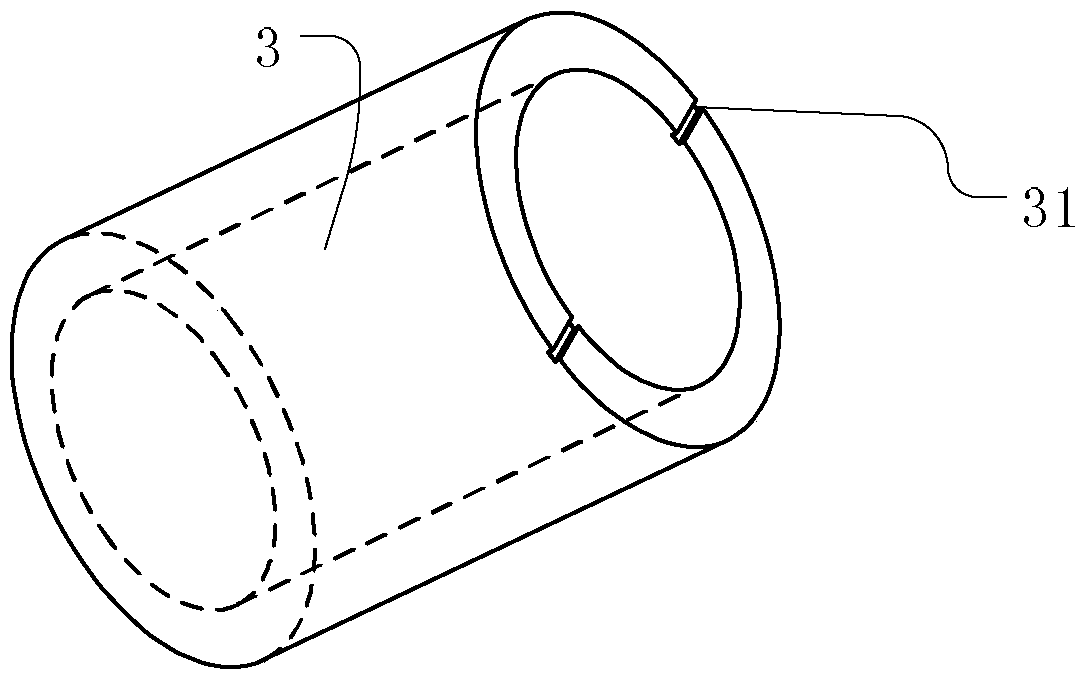

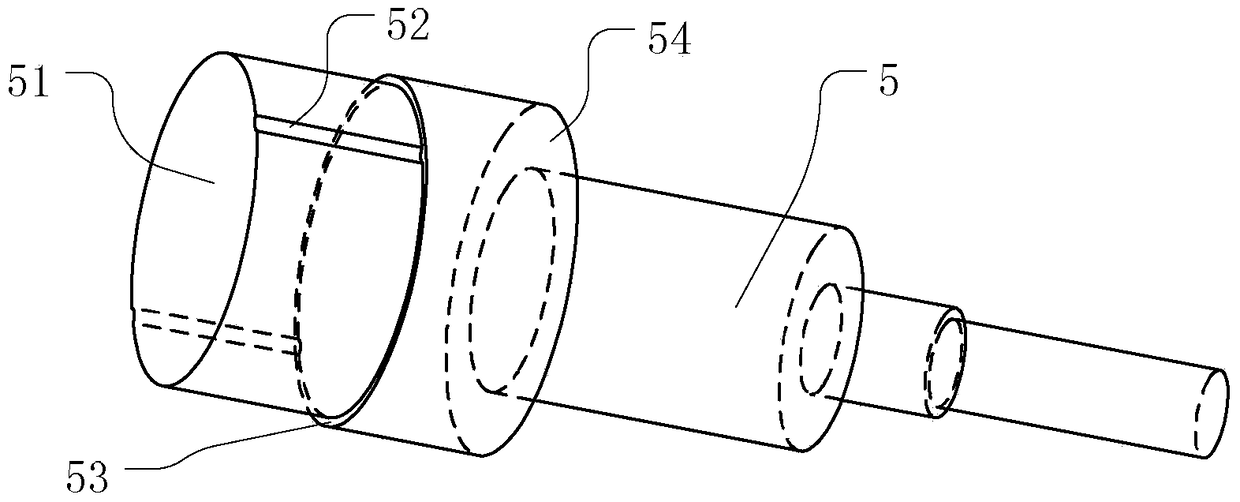

[0036] Such as Figure 1-5 As shown, the present application relates to a permanent magnet motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com