Linear Rotary Drilling Motor

A straight line and stator technology, applied in electromechanical devices, electrical components, propulsion systems, etc., can solve problems affecting work efficiency and economic benefits, difficult drilling positions or depths, and low drilling accuracy, so as to improve the utilization of internal space , Improve the torque/thrust density, reduce the effect of axial magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

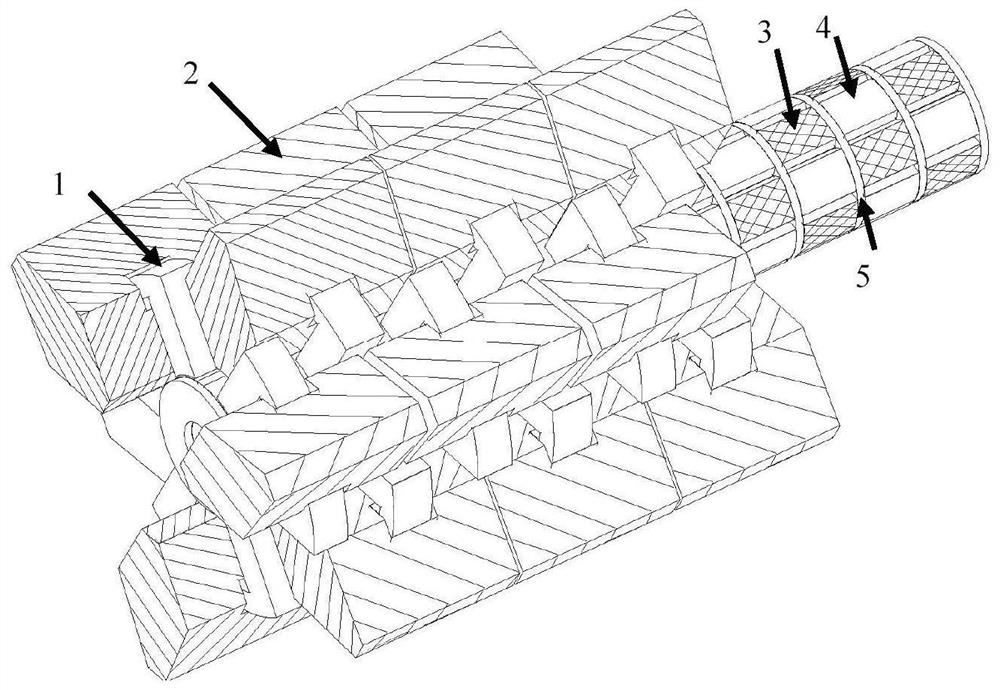

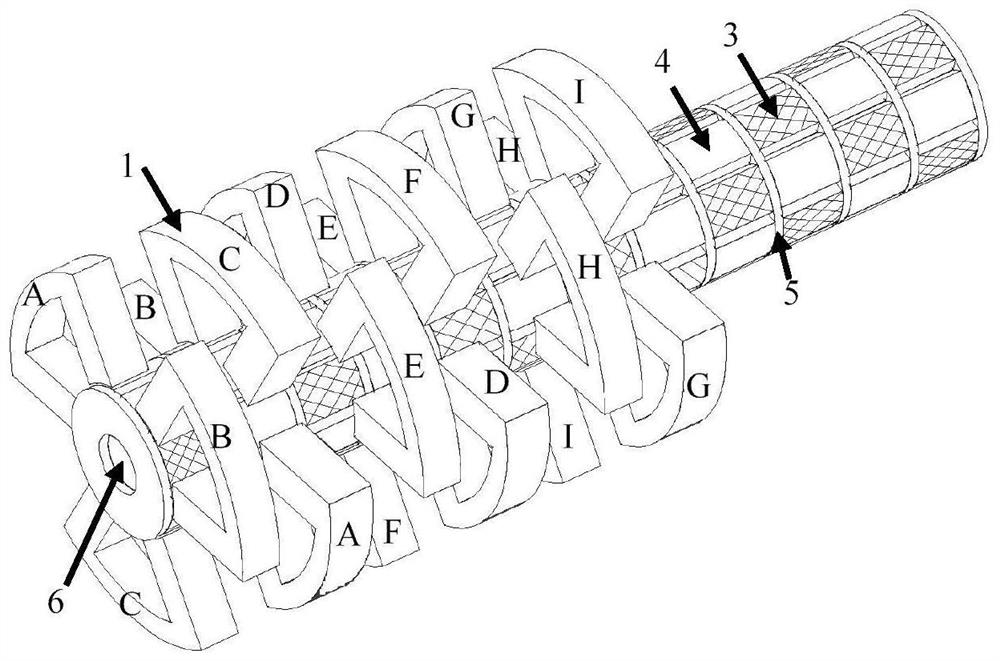

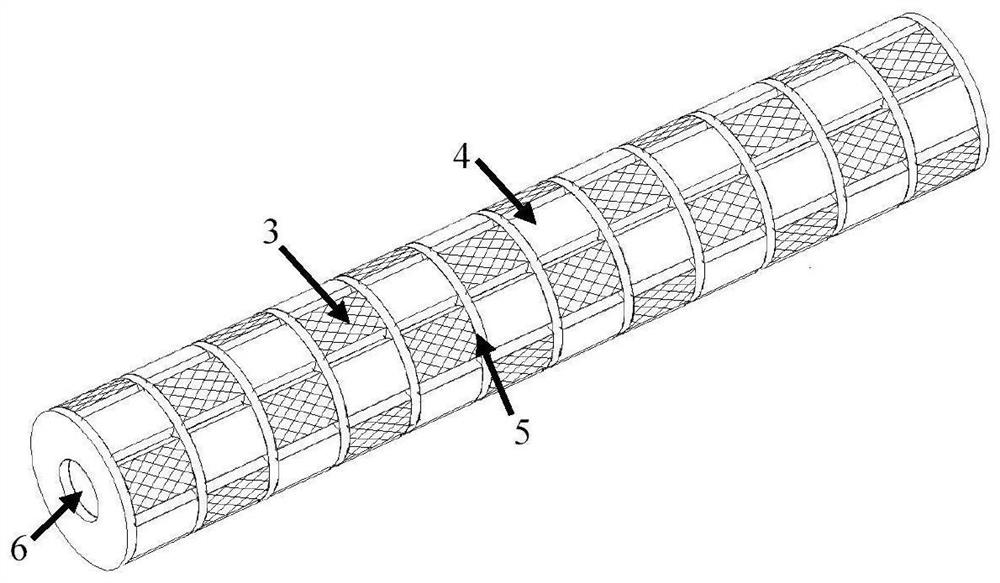

[0018] The linear rotary drilling motor, such as figure 1 As shown, the motor is composed of a U-shaped stator core (1), a ring winding (2), a permanent magnet S pole (3), a permanent magnet N pole (4) and a magnetic isolation ring (5). The mover structure is as follows image 3 As shown, it consists of a permanent magnet S pole (3), a permanent magnet N pole (4), a magnetic isolation ring (5) and a mover iron core (6).

[0019] The stator part of the motor has three U-shaped stator cores in the circumferential direction, and the winding control form is (A, B, C) (D, E, F) (G, H, I) when rotating, and in the axial direction U Stator cores are arranged in a staggered manner, and the control form of the winding is (A,D,G)(B,E,H)(C,F,I) during linear motion. The winding arrangement is as follows: figure 2 shown in . The ring winding can be wound and installed before the module is assembled, which simplifies the manufacturing and assembly process and reduces the cost of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com