Connecting rod pressure bushing jig with pressure head

A pressure head and lining technology, applied in the direction of connecting rods, manufacturing tools, metal processing, etc., can solve the problems of not meeting the requirements of drawing fit degree, affecting the fit degree of bushing and connecting rod, etc., so as to prevent pressing deformation , The effect of high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

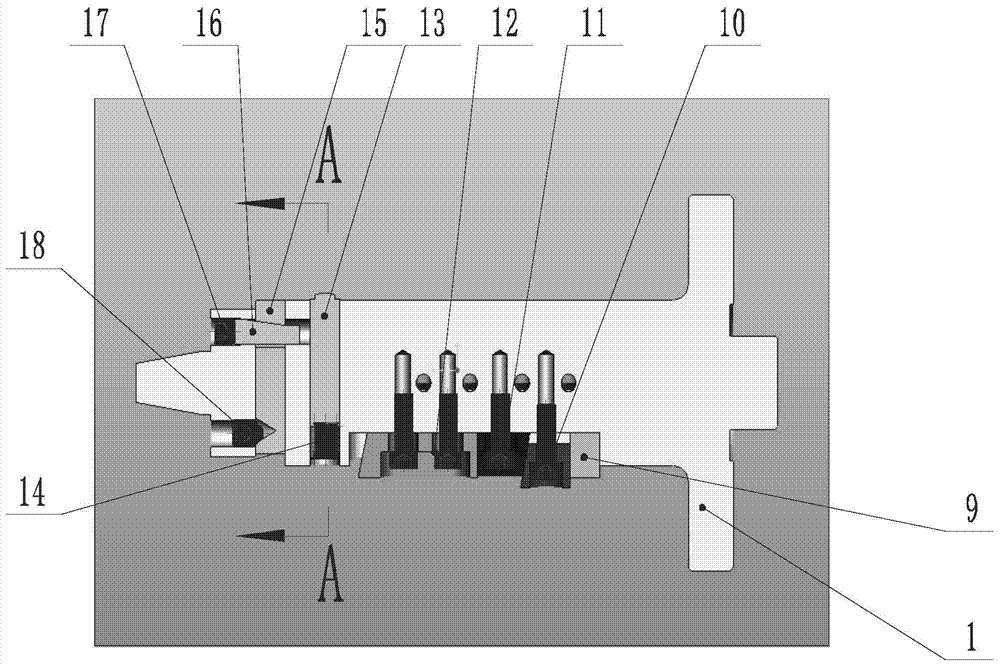

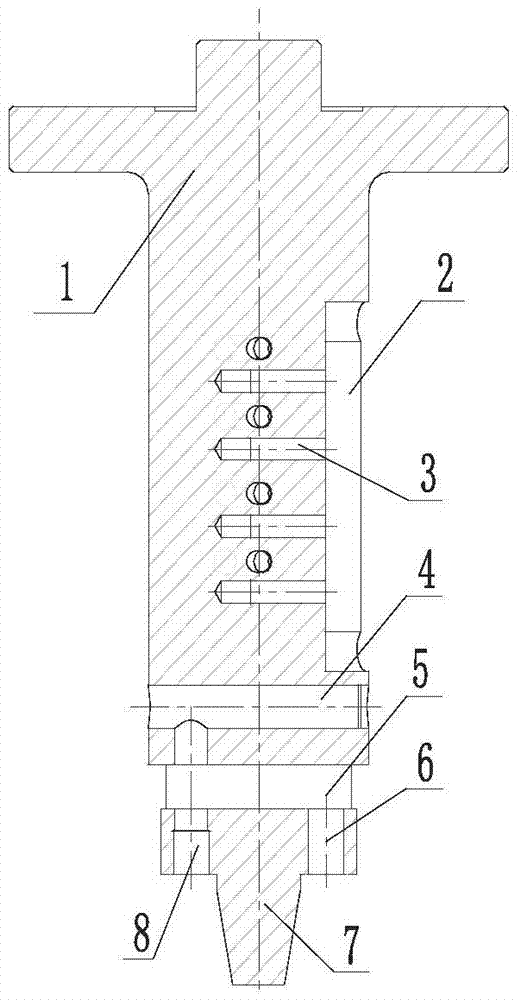

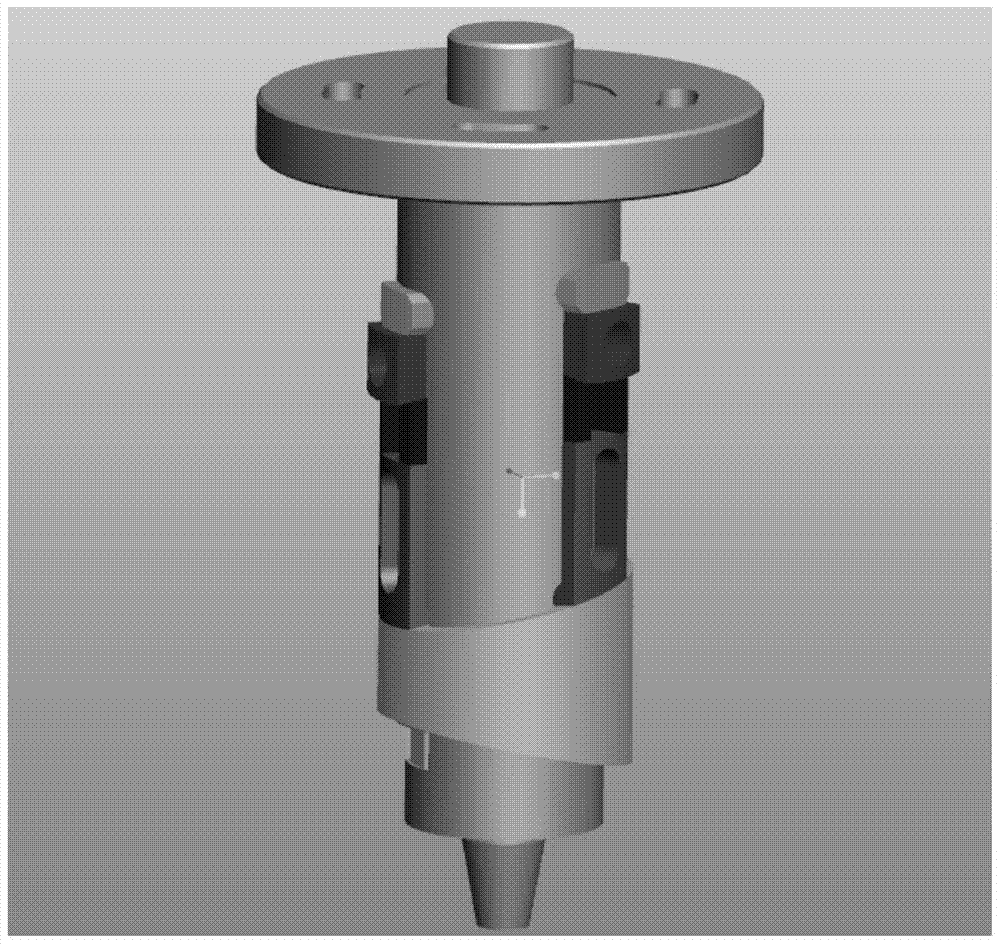

[0013] Embodiment 1: with reference to attached Figure 1-6 . An indenter for a connecting rod pressing bushing jig is characterized in that: the upper end of the indenter 1 is a machine tool connection surface 1, the lower end of the indenter 1 is a tapered column 7, and the head and body of the indenter 1 are provided with a plurality of grooves 2, each There are multiple countersunk holes 3 horizontally tapped on the bottom of the groove 2 from top to bottom. The lower part of the groove 2 is horizontally opened with a head hole 4 and a through hole 5 from top to bottom. The through thread hole 6 and the two-way through thread button hole 8; the pressing block 12, the lower wedge-shaped block 11, the upper wedge-shaped block 10, and the cushion block 9 are superimposed in sequence from bottom to top in the groove 2, and the pressing block 12, the lower wedge-shaped block The shape block 11 and the upper wedge shape block 10 are screwed with the respective countersunk screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com