Thermal shrinkage machine for production of flapwheel

A heat shrinking machine and thousand-sheet wheel technology, which is applied in metal processing equipment, grinding devices, grinding/polishing equipment, etc., can solve low production efficiency, high labor costs, and thousand-sheet wheels without abrasive belt cylinder casings and other problems, to achieve large tightening force, satisfy rapid shrinkage, and good arc guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described below with reference to the accompanying drawings and examples.

[0015] Glossary

[0016] Abrasive belt cylinder refers to a bundle of tubular abrasive belts bonded by a large number of abrasive belts, and its cross section is circular.

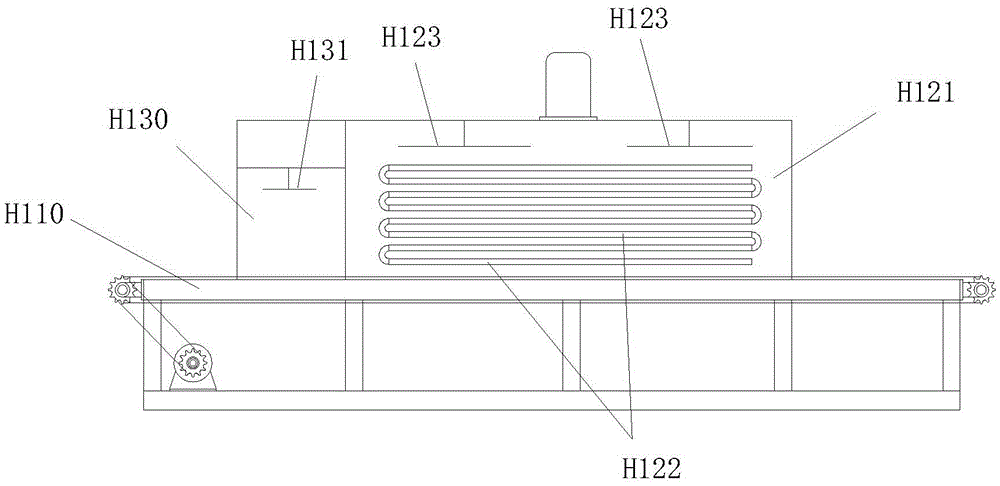

[0017] like figure 1 As shown, the present invention discloses a heat-shrinking machine structure for the production of thousand-page wheels. After the abrasive belt cylinder is arc-guided, a layer of heat-shrinkable film will be covered. After the heat-shrinkable film shrinks, the abrasive belt cylinder will be further tightened. It not only prevents the arc-guiding film from loosening, but also improves the arc-guiding effect of the abrasive belt cylinder. Wherein, the structure of the heat shrinking machine includes a conveyor belt H110 for conveying the abrasive belt cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com