Vacuum plate vulcanizing machine

A technology of flat vulcanizing machine and vulcanizing machine, applied in the direction of presses, manufacturing tools, etc., can solve the problems such as the inability to continuously produce belt-type high-elastic backing plates, achieve small hydraulic impact, reduce connecting pipelines and leakage points, and improve the leading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

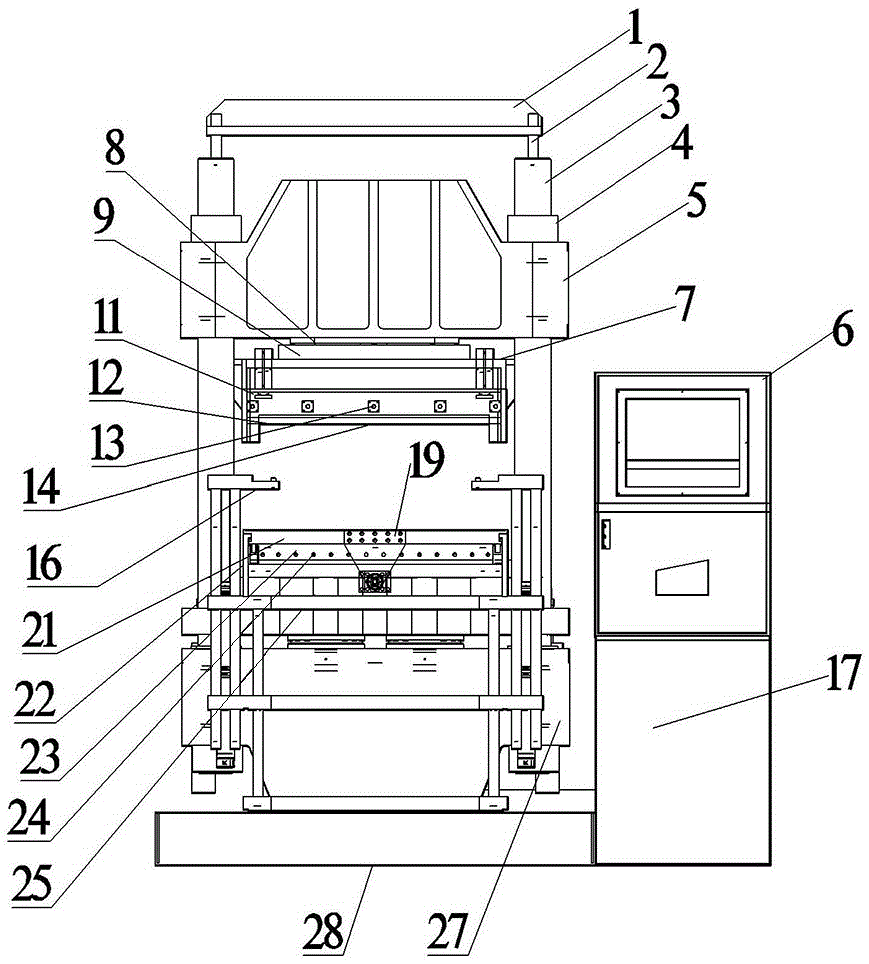

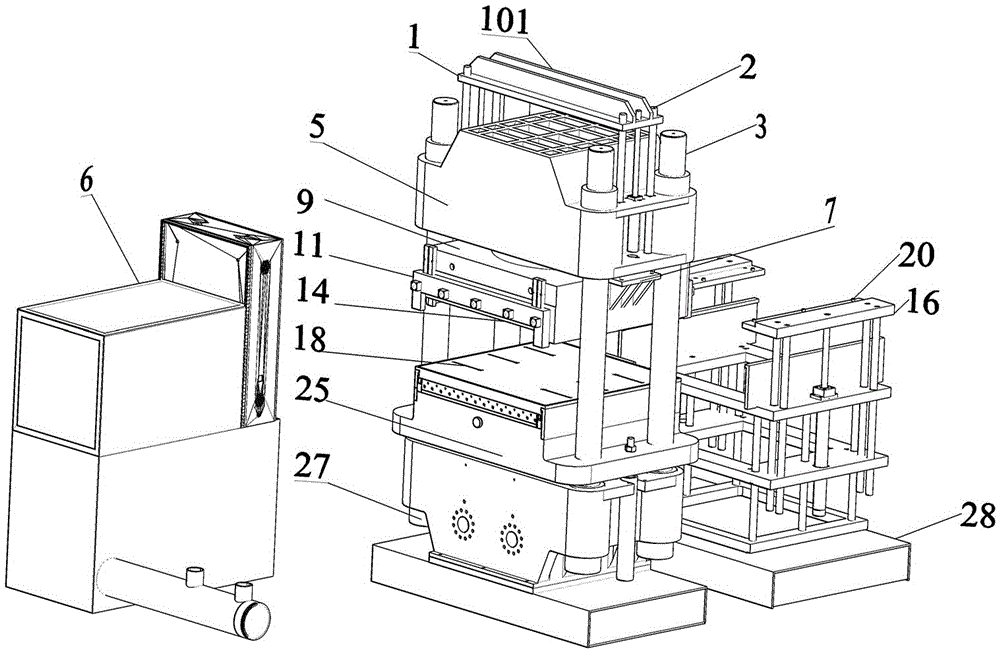

[0011] Such as Figure 1 to Figure 2 It can be seen that the present invention includes: a vulcanizing machine body 101, a vacuum box 28, and the vulcanizing machine body 101 includes: a vacuum plate 1, an upper seat 5, a vacuum cover 9, a middle seat 25, a lower template 23, and the vacuum plate 1 is fixed on the vacuum cover cylinder 2, the other end of the vacuum cover cylinder 2 passes through the upper seat 5 and is fixed on the vacuum cover slide plate 7, the vacuum slide plate cylinder 7 is fixed on the vacuum cover 9, and the vacuum cover 9 passes through The vacuum column connecting plate 8 is fixed on the bottom of the upper seat 5; the upper template 12 is built inside the vacuum cover 9; the other end of the large column 3 passes through the bottom and is fixed on the middle seat 25 and then connected with the main oil cylinder 27. The main piston 26 of the main oil cylinder 27 is connected with the middle seat 25, and the lower mold plate 23 and the lower mold sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com