Novel push rod turnover equipment

A technology of flipping equipment and push rods is applied in the field of stacker equipment and goods flipping in stacking equipment, which can solve the problems of high price of manipulators and high operation requirements, and achieve the effect of fast flipping and low manual intervention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

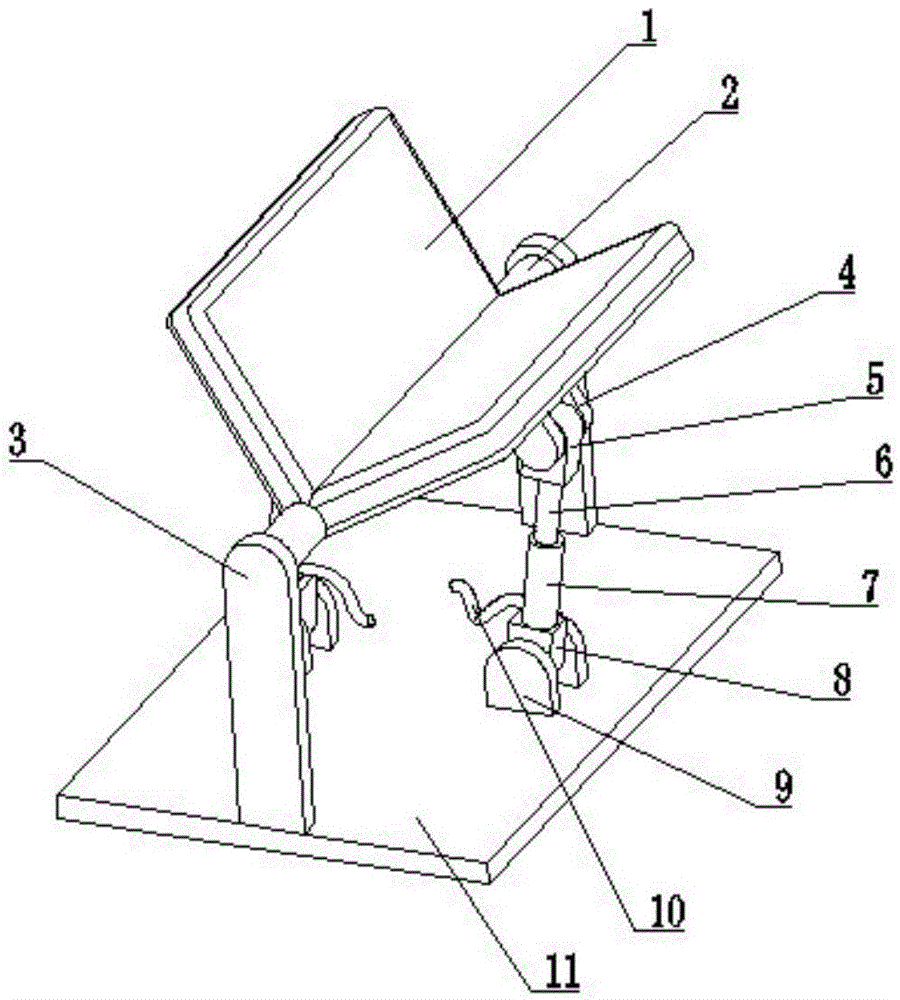

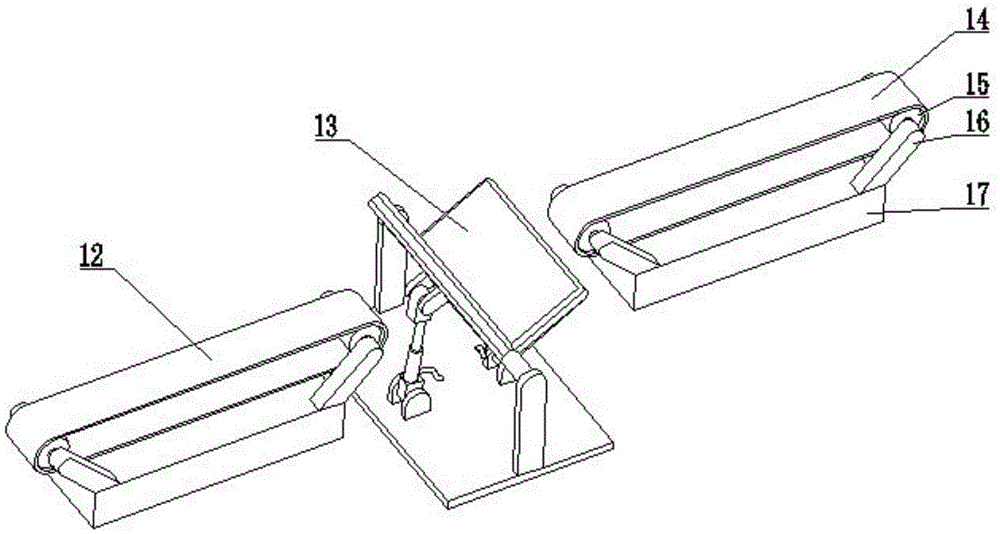

[0016] Refer to figure 1 with figure 2 , The present invention is a new type of push rod turning equipment, including a folding plate 1, a rotating shaft 2, a support rod 3, a hinge ring, a pneumatic rod 6, a pneumatic cylinder 7 and a bottom plate 11. The bottom plate 11 is fixedly installed with support rods at both ends 3. A rotating shaft 2 is installed at the upper end of the support rod 3, and the folding plate 1 is installed on the rotating shaft 2; the first hinge ring 4 is installed on the folding plate 1, and the first hinge ring 4 is hinged with the second hinge ring 5; The four hinged ring 9 is installed on the bottom plate 11, the third hinged ring 8 and the fourth hinged ring 9 are hinged; the second hinged ring 5 is fixedly connected with a pneumatic rod 6, and the third hinged ring 8 is fixedly connected with a pneumatic cylinder 7 , The pneumatic rod 6 is installed in cooperation with the pneumatic cylinder 7; the side of the pneumatic cylinder 7 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com