Building guard railing

A technology of guardrail and guardrail body, which is applied to buildings, building structures, railings, etc., can solve the problems of affecting aesthetics, cannot be reused, inconvenient for transportation and installation, etc., and achieves convenient transportation, firm installation, and convenient relative. moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

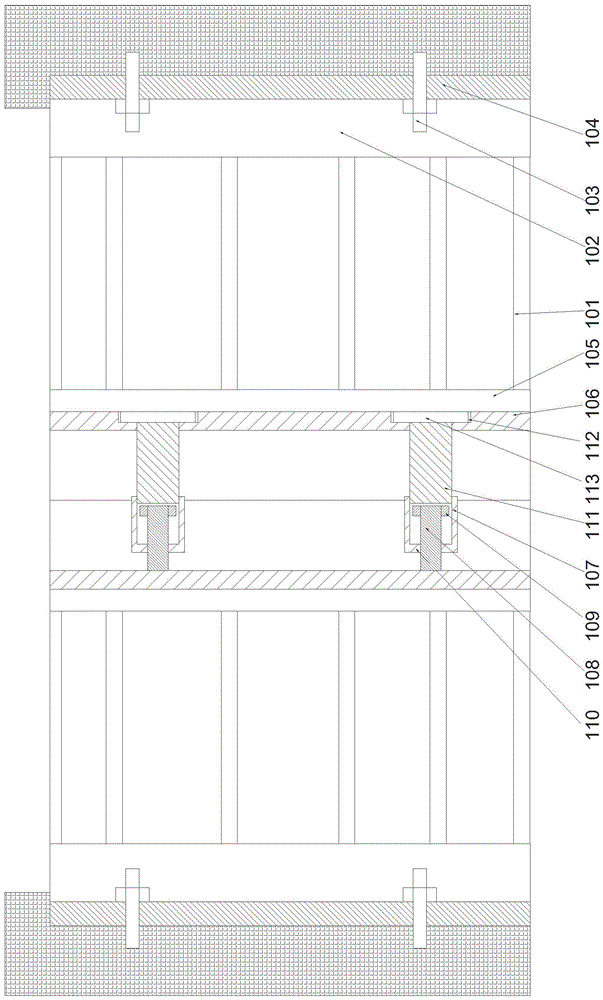

[0021] Such as figure 1 As shown, a building guardrail includes at least two interconnected guardrail bodies 101, and a fixing device is provided on one side of the guardrail body 101 located at the edge, and the fixing device includes embedded bolts 103 The fixed plate 102 fixedly connected to the building exterior wall is provided with a stepped groove 104 on one side of the fixed plate 102, and the stepped groove 104 is arranged along the length direction of the fixed plate 102. The embedded bolts 103 runs through the side wall of the stepped groove 104 and is fixedly connected to the inner side of the stepped groove 104 by nuts, and fixed ends 105 are respectively arranged on the adjacent guardrail body 101, and the fixed ends 105 and the fixed plate 102 are parallel to each other, fixed flanges 106 are respectively arranged in the middle of the same side of the fixed end 105, and the fixed flanges 106 are respectively arranged along the length direction of the fixed end 1...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, in order to facilitate the installation of the limiting part, in this embodiment, preferably, the end of the connecting sleeve 108 away from the fixing flange 106 is provided with an external thread, The limiting portion 109 is threadedly connected to the connecting sleeve 108 .

[0025] In order to facilitate the installation of the fixing rod, in this embodiment, preferably, a threaded hole is provided on the fixing flange 106 for installing the fixing rod 111, and the fixing rod 111 is screwed to the fixing rod 111. on the flange 106.

[0026] In order to make the structure of the fixed rod more stable and facilitate its installation, in this embodiment, preferably, a counterbore 112 is provided on the fixed flange 106 for installing the fixed rod 111, and a counterbore 112 is provided on the fixed rod 111. 111 is provided with a hexagon nut 113 at the end away from the connecting sleeve 108 , and the hexagon nut 113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com